Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

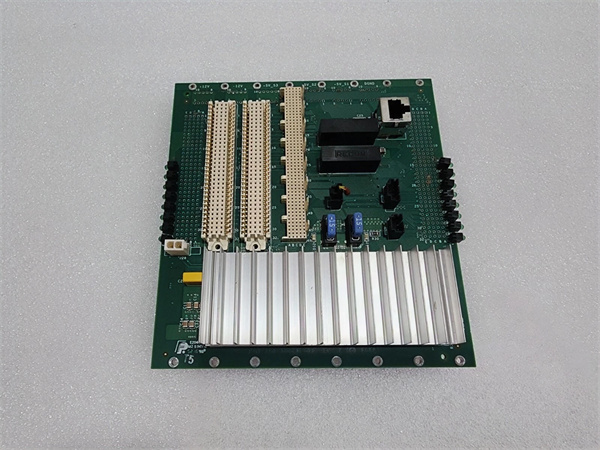

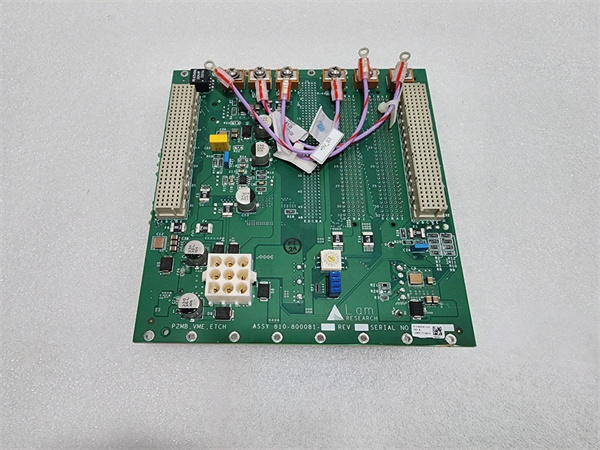

| Product model | 839-330743-002 |

| Manufacturer | LAM Research |

| Product category | Precision Temperature Control Module (for Semiconductor Processing Chambers) |

| Temperature Control Range | -20°C to +200°C (configurable via software) |

| Temperature Regulation Accuracy | ±0.1°C (at setpoint, 25–150°C); ±0.3°C (full range) |

| Temperature Sensing Inputs | 4x RTD inputs (Pt100, 3-wire/4-wire); 2x thermocouple inputs (Type K/J) |

| Heating/Cooling Outputs | 2x relay outputs (240V AC, 10A max) for heaters; 1x analog output (0–10V DC) for cooling valves |

| Interface Type | Ethernet (10/100Base-T); RS-485; 2x 32-pin terminal blocks (power/sensors/outputs); 1x USB-A (configuration) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary ThermalLink™ |

| Operating Temperature Range | 5°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 80% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 210mm × 300mm × 130mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (3U height); panel mounting (with optional brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Power Consumption | 100–240V AC (50/60 Hz), 1.2A typical; 2.0A maximum |

| Control Algorithm | PID (proportional-integral-derivative) with auto-tuning; on/off control (optional) |

| Over-Temperature Protection | Dual-stage (warning at 10°C above setpoint; shutdown at 15°C above setpoint) |

Product Introduction

The LAM 839-330743-002 is a high-precision temperature control module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered for integration into LAM’s flagship wafer processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the core thermal management unit for processing chambers, where stable temperatures are critical to wafer quality and process repeatability.

As a key model in LAM’s Thermal Control Series, the LAM 839-330743-002 is optimized for advanced semiconductor process nodes (down to 3nm), where even minute temperature fluctuations (±0.5°C or more) can distort thin-film deposition, alter etch profiles, or cause device defects. Its primary function is to monitor chamber temperatures via RTD/thermocouple sensors and adjust heating/cooling systems in real time to maintain user-defined setpoints. In automation systems, the LAM 839-330743-002 acts as a bridge between the main controller and thermal hardware, enabling seamless synchronization of temperature with other process parameters (e.g., gas flow, pressure)—ensuring consistent results across thousands of wafers.

Core Advantages and Technical Highlights

Ultra-Precise Temperature Regulation: The LAM 839-330743-002 delivers industry-leading temperature accuracy of ±0.1°C within its core operating range (25–150°C), a critical capability for 3nm/5nm process nodes. This precision is achieved through a advanced PID algorithm with auto-tuning, which continuously adjusts heating/cooling outputs based on sensor feedback (sampled 500 times per second). Unlike basic temperature controllers, it also compensates for ambient temperature drift and sensor lag, ensuring setpoint stability even during long production runs.

Multi-Sensor Compatibility and Redundancy: The LAM 839-330743-002 supports up to 6 temperature sensing inputs (4x Pt100 RTDs, 2x thermocouples), allowing fabs to monitor multiple zones within a single processing chamber (e.g., chamber wall, wafer stage, gas inlet). This multi-zone monitoring enables targeted thermal adjustments—for example, cooling the chamber wall while heating the wafer stage—to prevent condensation of process gases. Additionally, the module supports sensor redundancy (e.g., two RTDs for the same zone), triggering an alert if readings diverge by more than 0.5°C, which enhances process safety and reduces wafer scrappage.

Semiconductor-Grade Durability: Built to comply with SEMI S2/S8/S14 standards, the LAM 839-330743-002 features a corrosion-resistant aluminum housing and conformal-coated circuit boards that protect against low-level process gas leaks (e.g., fluorine, ammonia) common in etching/CVD systems. It also withstands electrostatic discharge (ESD) up to 15kV and vibration (10G peak, 10–500Hz)—critical for reliable operation in high-volume fabs with adjacent tool vibration. These design choices extend the module’s mean time between failures (MTBF) to over 180,000 hours.

User-Friendly Configuration and Diagnostics: The LAM 839-330743-002 simplifies setup via its USB-A port and LAM’s ThermalSuite™ configuration software, which allows users to define temperature setpoints, tune PID parameters, and set alarm thresholds with a graphical interface. It also includes built-in diagnostics that monitor sensor health, output circuit integrity, and power supply stability in real time. Faults (e.g., open RTD, over-temperature) are logged with time stamps and error codes, accessible via Ethernet or USB—enabling maintenance teams to quickly identify issues without shutting down the entire chamber.

Typical Application Scenarios

The LAM 839-330743-002 is indispensable in semiconductor fabs for thermal-critical processes, with two high-impact use cases: atomic layer deposition (ALD) for thin-film formation and plasma etching for advanced logic/memory devices.

In ALD (used for ultra-thin dielectric layers in 3D NAND), the LAM 839-330743-002 maintains the wafer stage at a precise temperature (typically 100–150°C) to ensure uniform precursor adsorption and reaction. Its ±0.1°C accuracy prevents uneven layer thickness (a common cause of device failure in 3D NAND), while multi-zone monitoring (chamber wall + stage) prevents precursor condensation on cold surfaces. Fabs using LAM’s Sym3® ALD systems rely on the LAM 839-330743-002 to maintain temperature stability across 24/7 production, directly improving yield by reducing layer defects by up to 25%.

In plasma etching for 3nm logic devices, the LAM 839-330743-002 controls the chamber wall temperature (often kept at -10–20°C) to manage plasma chemistry and prevent etch byproducts from depositing on the chamber interior. Its dual-stage over-temperature protection also safeguards the chamber from thermal damage if the cooling system fails—critical, as chamber repairs can cost tens of thousands of dollars and halt production for days. The module’s compatibility with LAM’s ControlLink™ protocol further allows it to sync with gas flow modules (e.g., LAM 739-090783-001) and high-voltage power supplies (e.g., LAM 810-800082-043), ensuring all process parameters work in harmony.

LAM 810-800081-022

Related Model Recommendations

LAM 839-330743-003: An upgraded variant of the LAM 839-330743-002 with extended temperature range (-40°C to +300°C) and additional outputs (4x relay outputs), designed for high-temperature processes like metal organic CVD (MOCVD).

LAM 839-330743-001: A lower-cost variant of the LAM 839-330743-002 with reduced sensor inputs (2x RTDs, 1x thermocouple) and no analog cooling output, ideal for R&D labs or low-volume etching tools.

LAM 839-330744-002: A redundant temperature control module that pairs with the LAM 839-330743-002 for fault-tolerant systems (e.g., high-yield memory fabs), automatically taking over if the primary module fails to prevent chamber shutdown.

LAM 839-330742-002: A legacy replacement for LAM’s pre-2016 temperature controllers (e.g., 839-330739-001), fully compatible with the LAM 839-330743-002’s mounting, power, and protocol support.

LAM 839-330743-004: A wireless-enabled variant of the LAM 839-330743-002 (Wi-Fi 6, Bluetooth 5.2), enabling remote monitoring of chamber temperatures in hard-to-access cleanroom areas.

LAM 839-330745-002: A temperature monitoring accessory module that adds 8x additional RTD inputs to the LAM 839-330743-002, ideal for large chambers with multiple thermal zones (e.g., 300mm wafer etchers).

LAM 839-330743-005: A safety-enhanced variant of the LAM 839-330743-002 with SIL 2 certification, designed for tools with critical thermal safety requirements (e.g., high-temperature CVD chambers).

LAM 839-330746-002: A calibration accessory module that provides NIST-traceable temperature references for the LAM 839-330743-002, simplifying on-site calibration and ensuring long-term accuracy.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the LAM 839-330743-002, ensure the 19-inch rack or panel is clean (free of particulate matter) and the ambient temperature is within 5–45°C. Required tools include a torque wrench (2.5 N·m for rack mounting), multimeter (to verify AC power), ESD-safe gloves/wristbands, and a laptop (for USB configuration). Safety precautions: Disconnect AC power to the host system before wiring; use shielded cables for RTD/thermocouple inputs to minimize electromagnetic interference (EMI); and confirm the module’s ground connection (≥10AWG wire) is secure to prevent ESD damage. Avoid mounting near high-voltage components (e.g., plasma power supplies) or cooling fans to prevent temperature drift from airflow.

Maintenance Suggestions: For daily maintenance, check the LAM 839-330743-002’s front-panel LED indicators (green = normal, amber = temperature warning, red = fault) and verify setpoint stability via the Ethernet interface. Every 6 months, perform a sensor calibration using LAM’s ThermalCal™ tool (traceable to NIST standards) to maintain ±0.1°C accuracy. If a fault occurs (e.g., open RTD), first isolate the module from power, inspect sensor wiring for damage, and replace faulty sensors with LAM-approved Pt100/Type K components—non-approved sensors may cause accuracy issues or void the warranty. Every 12 months, inspect the module’s conformal coating for signs of wear or corrosion; if damage is found, contact LAM’s service team for professional re-coating to maintain SEMI compliance. Additionally, update the module’s firmware annually via USB using LAM’s ThermalSuite™ software to access new features and performance improvements.

Service and Guarantee Commitment

The LAM 839-330743-002 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and temperature control accuracy under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “swap-and-calibrate” service—delivering a pre-calibrated replacement unit within 48 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers comprehensive technical support for the LAM 839-330743-002, including 24/7 access to thermal control specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 72 hours for global fabs). The module also includes free access to LAM’s ThermalSuite™ software (for configuration, calibration, and firmware updates) for 5 years post-purchase, ensuring long-term compatibility with evolving process needs.

To enhance reliability, LAM offers a Thermal Care Program for the LAM 839-330743-002, which includes scheduled on-site inspections, proactive sensor replacement, and annual NIST-traceable calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the LAM 839-330743-002’s quality and its dedication to supporting customers’ critical semiconductor manufacturing operations.