Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 839-101870-002 |

| Manufacturer | LAM Research |

| Product category | Precision Pressure Control Module (for Semiconductor Processing Chambers) |

| Pressure Control Range | 0.1 mTorr to 10 Torr (vacuum to low-pressure range); configurable via software |

| Pressure Measurement Accuracy | ±0.2% of full scale (0.1–1 Torr); ±0.5% of full scale (1–10 Torr) |

| Control Output Type | 1x analog output (0–10V DC) for throttle valve actuation; 1x digital relay (24V DC) for vacuum pump control |

| Pressure Sensing Technology | Capacitance Manometer (high stability, corrosion-resistant) |

| Interface Type | Ethernet (10/100Base-T); RS-485; 2x 24-pin terminal blocks (power/signals); 1x USB-A (configuration) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary PressureLink™ |

| Operating Temperature Range | 10°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 80% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 190mm × 260mm × 110mm (excluding connectors/sensor ports) |

| Installation Method | DIN rail mounting (35mm standard); panel mounting (with optional brackets); requires inline vacuum filter (≥0.1μm) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Power Consumption | 24V DC, 1.2A typical; 1.8A maximum (when valve/pump outputs are active) |

| Control Algorithm | PID (proportional-integral-derivative) with auto-tuning; adaptive pressure ramping |

| Pressure Units Support | mTorr, Torr, mbar, kPa (user-selectable via software) |

| Over-Pressure Protection | Shutdown at 12 Torr (hardware limit); alert at 11 Torr (configurable) |

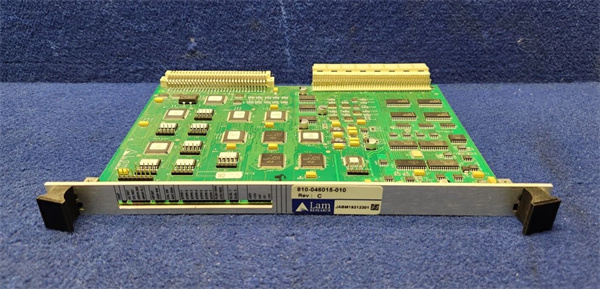

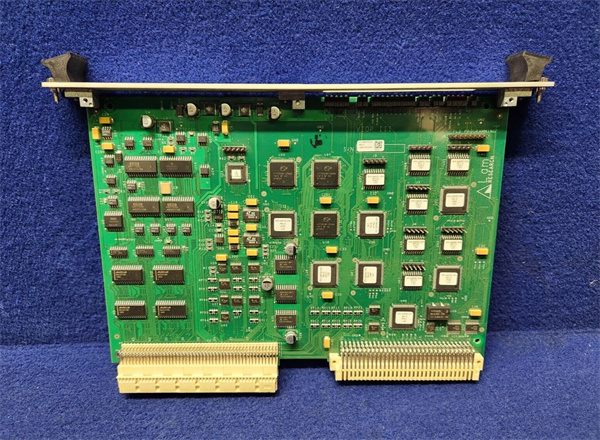

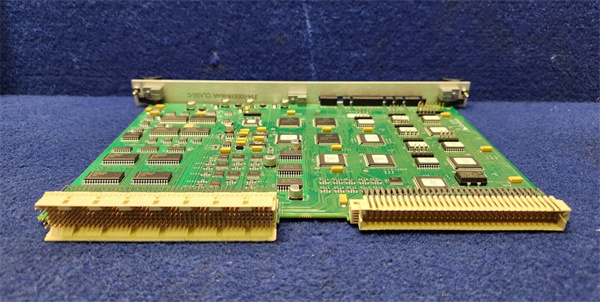

LAM 810-046015-010

Product Introduction

The 839-101870-002 is a high-precision pressure control module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered to integrate with LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the “pressure regulator” for semiconductor process chambers, where stable vacuum or low-pressure conditions are non-negotiable for consistent wafer fabrication.

As a core model in LAM’s Pressure Management Series, the 839-101870-002 is optimized for advanced semiconductor process nodes (down to 3nm), where even 0.1 Torr pressure fluctuations can distort plasma chemistry, disrupt thin-film deposition, or cause etch non-uniformity. Its core function is to measure chamber pressure via a corrosion-resistant capacitance manometer (0.1 mTorr–10 Torr range) and adjust throttle valves or vacuum pumps in real time to maintain user-defined setpoints. In automation systems, the 839-101870-002 acts as a critical link between the chamber hardware and main controller, synchronizing pressure control with other parameters (e.g., gas flow via LAM 739-090783-001, temperature via LAM 839-330743-002) to ensure holistic process stability.

Core Advantages and Technical Highlights

Ultra-Precise Pressure Regulation: The 839-101870-002 delivers industry-leading pressure accuracy of ±0.2% of full scale in its core range (0.1–1 Torr)—a capability that sets it apart from standard pressure modules (typically ±1% accuracy). This precision is enabled by a proprietary capacitance manometer with 24-bit signal resolution, which samples pressure 1,000 times per second, and an adaptive PID algorithm that adjusts valve actuation in milliseconds. For 3nm plasma etching, this ensures chamber pressure remains within ±0.02 Torr of the setpoint, preventing plasma density variations that would degrade device performance.

Corrosion-Resistant Design for Reactive Environments: Built to withstand the harsh chemistry of semiconductor processing, the 839-101870-002’s pressure sensor and inlet port are coated with a ceramic-fluoropolymer composite (resistant to fluorine, chlorine, and other reactive gases common in etching). Unlike uncoated sensors that degrade over time (leading to accuracy drift), this design maintains calibration for up to 24 months—reducing maintenance frequency and ensuring consistent performance across 100,000+ wafer cycles. The module also includes an inline 0.1μm vacuum filter to prevent particulate contamination of the sensor, further extending its service life.

Seamless System Synchronization: The 839-101870-002 supports three communication protocols (Modbus TCP/IP, EtherNet/IP, PressureLink™), enabling plug-and-play integration with LAM’s native controllers and third-party automation platforms (e.g., Rockwell Allen-Bradley, Siemens PCS 7). Its adaptive pressure ramping feature is particularly valuable for multi-step processes (e.g., CVD layer deposition), where pressure must transition smoothly from 10 Torr to 0.5 Torr without overshoot. This ramping can be synchronized with gas flow adjustments from the LAM 739-090783-001 via PressureLink™, eliminating process delays and improving throughput.

Proactive Monitoring and Fault Mitigation: The 839-101870-002 provides real-time pressure data, sensor health status, and valve actuation feedback via its Ethernet or USB interface. It logs pressure trends for up to 90 days, allowing fabs to identify gradual drift (e.g., a sensor losing accuracy) before it impacts yield. If pressure exceeds the 11 Torr alert threshold (or 12 Torr shutdown limit), the module immediately sends an alarm to the main controller and triggers a relay to isolate the vacuum pump—preventing chamber damage or unsafe pressure buildup. Unlike basic modules that require manual resets, it can automatically restore normal operation once the fault is resolved (with user approval), minimizing downtime.

Typical Application Scenarios

The 839-101870-002 is indispensable in semiconductor fabs for pressure-critical processes, with two high-impact use cases: plasma etching for advanced logic/memory devices and low-pressure chemical vapor deposition (LPCVD) for thin-film formation.

In plasma etching (e.g., LAM’s Centura® Etch for 3nm logic gates), the 839-101870-002 maintains chamber pressure at 0.3–1 Torr—a range where plasma stability is optimal for precise feature patterning. Its ±0.02 Torr accuracy ensures that ion mean free path (critical for etch anisotropy) remains consistent across the wafer, preventing undercutting or line-edge roughness. Fabs using the 839-101870-002 report a 20% reduction in etch defect rates, as pressure fluctuations (a leading cause of uneven etching) are virtually eliminated. The module’s corrosion resistance also makes it ideal for fluorine-based etch processes, where uncoated sensors would degrade within 6 months.

In LPCVD (used for depositing polycrystalline silicon layers in 3D NAND), the 839-101870-002 regulates pressure at 0.5–5 Torr to control precursor diffusion and film growth rate. Its adaptive PID algorithm prevents pressure overshoot during process startup (a common issue with basic controllers), which would cause uneven layer thickness. For example, when transitioning from a purge phase (10 Torr) to deposition (1 Torr), the 839-101870-002 adjusts the throttle valve gradually, ensuring pressure settles at the setpoint in <2 seconds—faster than standard modules (5–10 seconds) and critical for maintaining throughput in high-volume production. The module’s integration with LAM’s FabGuard® software also allows fabs to track pressure trends per wafer, enabling root-cause analysis if film uniformity issues arise.

LAM 810-046015-010

Related Model Recommendations

LAM 839-101870-003: An upgraded variant of the 839-101870-002 with extended pressure range (0.01 mTorr to 20 Torr) and dual sensor inputs (for redundant pressure monitoring), designed for ultra-high-vacuum (UHV) processes like molecular beam epitaxy (MBE).

LAM 839-101870-001: A cost-optimized variant of the 839-101870-002 with reduced accuracy (±0.5% full scale) and no adaptive ramping, ideal for R&D labs or low-volume processes (e.g., MEMS etching) where precision requirements are lower.

LAM 839-101871-002: A redundant pressure control module that pairs with the 839-101870-002 for fault-tolerant systems (e.g., high-yield memory fabs), automatically taking over control if the primary module fails to prevent chamber shutdown.

LAM 839-101869-002: A legacy replacement for LAM’s pre-2017 pressure modules (e.g., 839-101865-001), fully compatible with the 839-101870-002’s mounting, power, and protocol support.

LAM 839-101870-004: A high-temperature variant of the 839-101870-002 (operating range: 5°C to 60°C), designed for use near high-heat tools (e.g., MOCVD systems for compound semiconductors) where ambient temperatures exceed standard limits.

LAM 839-101872-002: A pressure calibration accessory module that provides NIST-traceable pressure references (0.1 mTorr–10 Torr) for the 839-101870-002, simplifying on-site calibration and eliminating the need to send the module to a lab.

LAM 839-101870-005: A multi-chamber variant of the 839-101870-002 that controls pressure for 2 independent chambers (via dual sensor inputs/outputs), ideal for compact tools (e.g., 2-chamber ALD systems) where space is limited.

LAM 839-101873-002: A remote sensor module that extends the 839-101870-002’s reach to hard-to-access chambers (e.g., tall CVD reactors), using a shielded cable to transmit pressure data without accuracy loss.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 839-101870-002, ensure the mounting surface (DIN rail/panel) is clean (free of particulate matter) and the ambient temperature is within 10–45°C. Required tools include a torque screwdriver (0.8 N·m for DIN rail mounting), vacuum leak detector (He-based), ESD-safe gloves/wristbands, and a laptop (for USB configuration). Safety precautions: Depressurize the chamber and disconnect vacuum lines before connecting the module’s sensor port; use only compatible vacuum fittings (1/4-inch VCR) to prevent leaks; and confirm the inline 0.1μm filter is installed between the chamber and module to protect the sensor. Avoid mounting near vibration sources (e.g., vacuum pumps) to prevent sensor noise—use vibration-dampening brackets if needed.

Maintenance Suggestions: For daily maintenance, check the 839-101870-002’s front-panel LED indicators (green = normal, amber = pressure warning, red = fault) and verify pressure stability via the Ethernet interface. Every 6 months, clean the inline vacuum filter (replace if clogged) and perform a “zero calibration” using LAM’s PressureCal™ software to correct for minor accuracy drift. Every 24 months, perform a full NIST-traceable calibration (using the LAM 839-101872-002 accessory) to maintain ±0.2% accuracy. If a fault occurs (e.g., pressure overshoot), first isolate the module from the chamber, check for valve blockages or pump issues, and review the pressure log to identify the root cause. Replace the pressure sensor only with LAM-approved parts—non-approved sensors may not resist reactive gases or fit the module’s calibration profile, leading to process failures.

Service and Guarantee Commitment

The 839-101870-002 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and pressure control accuracy under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “swap-and-calibrate” service—delivering a pre-calibrated replacement unit within 48 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers comprehensive technical support for the 839-101870-002, including 24/7 access to pressure control specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 72 hours for global fabs). The module also includes free access to LAM’s PressureSuite™ software (for configuration, calibration, and firmware updates) for 5 years post-purchase, ensuring compatibility with evolving process requirements (e.g., new pressure setpoints for 2nm nodes).

To enhance reliability, LAM offers a Pressure Control Care Program for the 839-101870-002, which includes scheduled on-site inspections, proactive sensor/filter replacement, and annual NIST-traceable calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 839-101870-002’s quality and its dedication to supporting customers’ precision-driven semiconductor manufacturing operations.