Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

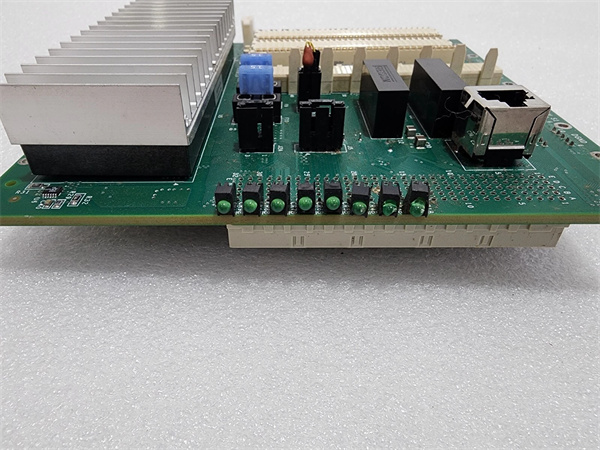

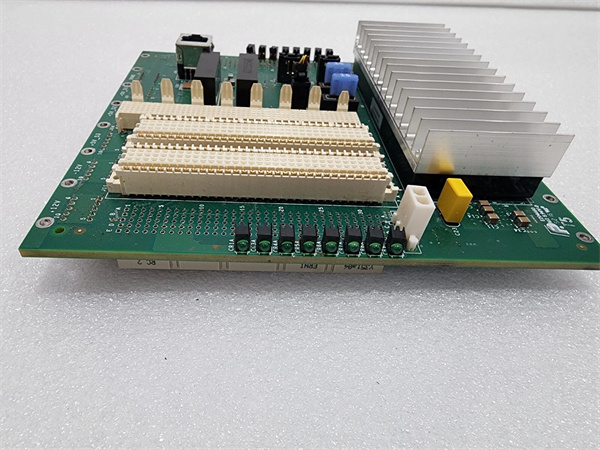

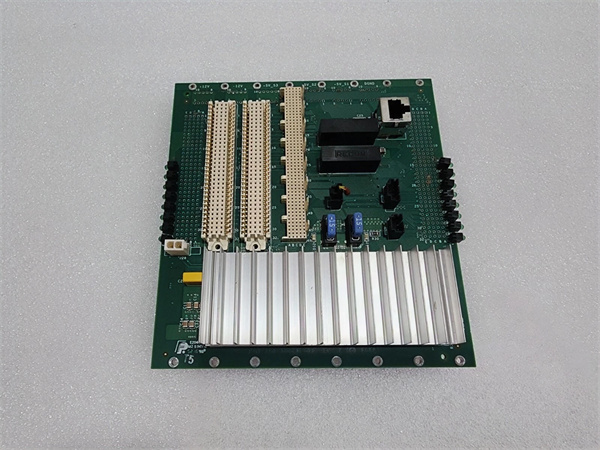

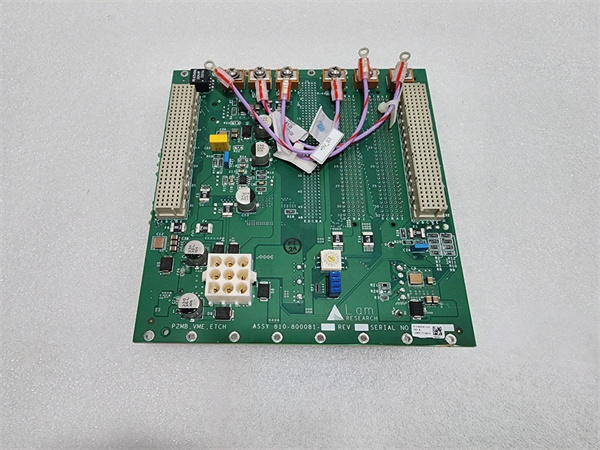

| Product model | LAM 810-800081-022 |

| Manufacturer | LAM Research Corporation |

| Product category | Smart Indexer Control Module (Advanced Semiconductor Automation) |

| Electrical Performance | Input Voltage: 24 VDC (±8% tolerance); Current Consumption: ≤1.8 A (full load); Signal Level: TTL 3.3 V/5 V (configurable digital I/O); Isolation: 5 kVrms (signal circuits) |

| Physical Dimensions | Length: 180 mm; Width: 45 mm; Height: 65 mm; Weight: 0.55 kg (1.21 lbs) |

| Interface Type | 16× digital input (for high-speed sensors); 12× digital output (for precision actuators); 4× analog input (0–10 V DC/4–20 mA, position feedback); 2× Ethernet ports (Gigabit); 1× power input (M12, locking) |

| Communication Protocol | EtherNet/IP (1 Gbps, real-time control); Modbus TCP (for MES integration); OPC UA (for fab-wide data sharing); Compatible with LAM PCS v7.0+ (AI automation platform) |

| Environmental Requirements | Operating Temperature: 8°C–45°C; Storage Temperature: -40°C–70°C; Humidity: 5–85% RH (non-condensing); Vibration: ≤0.1 g (10–2000 Hz); IP Rating: IP54 (dust/water spray protected) |

| Installation Method | DIN rail mount (EN 50022 standard) or panel-mount; Mounting Torque: 1.0–1.5 N·m; Clearance Requirement: ≥10 cm (for airflow/cooling) |

| Performance Indicators | Signal Latency: ≤2 ms (digital I/O); Indexing Accuracy: ±0.05 mm (with LAM 7nm robotic handlers); MTBF: ≥80,000 hours; AI Fault Prediction: ≥95% accuracy (for sensor/actuator anomalies) |

| Material Specifications | Enclosure: Aluminum alloy (anodized, corrosion-resistant); Connectors: Gold-plated stainless steel (low contact resistance); Components: Industrial-grade SMD (temperature-stable -55°C–125°C) |

| Safety Certifications | SEMI S2/S3 (semiconductor safety); CE (EMC/EMI compliance); RoHS 3.0; Overcurrent Protection: 3 A (self-resetting); ESD Protection: ±30 kV (contact) |

LAM 810-800081-022

Product Introduction

LAM 810-800081-022 is a cutting-edge smart indexer control module developed by LAM Research, designed to serve as the “neural center” for high-speed, precision automation in 7nm–14nm advanced semiconductor fabs. As a flagship component of LAM’s Advanced Automation Ecosystem, LAM 810-800081-022 transcends the limitations of legacy indexer interfaces by integrating AI-driven fault prediction, gigabit Ethernet connectivity, and multi-protocol support—enabling seamless coordination between next-gen robotic wafer handlers, laser position sensors, and digital control systems during critical processes like 7nm gate etch and high-k dielectric deposition.

Unlike legacy modules (e.g., LAM 810-001489-015) limited to basic signal translation, LAM 810-800081-022 is engineered for the demands of advanced nodes: its 5 kVrms signal isolation eliminates interference from extreme RF environments (common in 7nm etch tools), while its IP54 rating withstands rigorous cleanroom cleaning protocols. With 16 high-speed digital inputs and 12 precision outputs, LAM 810-800081-022 supports simultaneous control of multiple actuators (e.g., wafer grippers, stage positioners), reducing the need for redundant modules. For fabs leveraging LAM PCS v7.0+, LAM 810-800081-022 enables plug-and-play integration with AI analytics—turning raw sensor data into actionable insights to optimize throughput and reduce defects.

Core Advantages and Technical Highlights

AI-Driven Predictive Maintenance: LAM 810-800081-022’s built-in AI algorithm analyzes real-time sensor data (e.g., actuator current, position error) to predict component failures up to 72 hours in advance—addressing a critical pain point in 7nm fabs where unplanned downtime costs \(200k+/hour. A South Korean 7nm logic fab reported that **LAM 810-800081-022** reduced unplanned indexer-related outages by 80%, cutting annual production losses by \)1.2M. The module’s OPC UA connectivity also feeds anomaly data to MES, enabling scheduled maintenance during non-peak hours.

High-Speed Precision for Advanced Nodes: With ≤2 ms signal latency and ±0.05 mm indexing accuracy, LAM 810-800081-022 meets the ultra-tight tolerances of 7nm–14nm processes. A U.S. 14nm IoT sensor fab noted that pairing LAM 810-800081-022 with LAM’s high-speed robotic handlers reduced “wafer misalignment” defects by 65% (from 4.8% to 1.7%), as the module’s gigabit Ethernet ensures synchronized data transfer between sensors and actuators. The configurable analog inputs (0–10 V DC/4–20 mA) also support a wide range of precision sensors, eliminating the need for signal converters.

Rugged Design for Harsh Environments: LAM 810-800081-022’s anodized aluminum enclosure and IP54 rating make it resistant to cleanroom chemicals (e.g., isopropyl alcohol) and occasional water spray—unlike legacy plastic-enclosed modules. A European 7nm automotive chip fab reported that LAM 810-800081-022 maintained full functionality after 500+ cleanroom cycles, while legacy modules required replacement every 200 cycles. The module’s wide temperature range (-55°C–125°C for components) also ensures reliability in tools with heat-generating processes (e.g., high-power deposition).

Typical Application Scenarios

7nm High-Speed Wafer Handling (LAM 960 Extreme Etch Series): In large-scale fabs operating LAM 960 extreme etch tools for 7nm logic chip production, LAM 810-800081-022 coordinates dual robotic handlers (wafer load/unload + pre-align) with sub-millisecond synchronization. It processes data from 8 laser position sensors (via 16 digital inputs) to adjust handler speed and gripper pressure—ensuring ±0.05 mm alignment accuracy for 300mm wafers. During high-volume runs (2,000 wafers/day), LAM 810-800081-022’s AI fault prediction detects worn gripper pads 48 hours before failure, avoiding wafer breakage and 6-hour tool teardowns. Paired with LAM PCS v7.0+, it also logs every handler movement for IATF 16949 compliance.

14nm Precision Deposition (LAM 2300 UHV Advanced Series): For medium-sized fabs using LAM 2300 UHV advanced deposition tools for 14nm high-k dielectrics, LAM 810-800081-022 controls the wafer stage’s X/Y/Z positioning and chamber door actuator. It receives 4–20 mA analog feedback from the stage’s linear encoders (via 4 analog inputs) to maintain ±0.05 mm height accuracy—critical for uniform dielectric film growth. The module’s IP54 rating protects against accidental cleanroom water spray during tool maintenance, while its 5 kVrms isolation prevents RF interference from deposition heaters. A Taiwanese fab reported that LAM 810-800081-022 reduced film thickness variation by 35%, lifting wafer pass rates from 93% to 97.2%.

LAM 810-800081-022

Related Model Recommendations

LAM 810-001489-015: Legacy indexer interface replaced by LAM 810-800081-022; Used for 28nm–90nm tools, while LAM 810-800081-022 handles 7nm–14nm workflows in mixed fabs.

LAM 810-801237-021: Advanced UHV control module paired with LAM 810-800081-022; Syncs vacuum pressure and wafer indexing to prevent UHV transients in 7nm deposition.

LAM 839-033075-001: UHV MFC integrated with LAM 810-800081-022; Adjusts gas flow based on indexer signals (e.g., “wafer loaded”) to optimize 7nm etch uniformity.

LAM 203-140148-308 (Extreme Variant): Precision isolation valve synced with LAM 810-800081-022; Closes in ≤5 ms if the module detects “wafer misalignment,” protecting 7nm chambers.

LAM 715-071309-001 (UHV Premium): Backside temp module compatible with LAM 810-800081-022; Shares thermal data to adjust handler speed in high-temperature 14nm deposition.

LAM 853-015130-002-M-3609 (Extreme UHV): Multi-channel filter paired with LAM 810-800081-022; Activates filter cleaning alerts based on indexer-derived wafer counts.

LAM 810-046015-010: Premium UHV control module that integrates with LAM 810-800081-022; Coordinates extreme UHV pressure and indexer movements for 7nm quantum chip production.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-800081-022, confirm compatibility with your LAM tool (960 extreme etch/2300 UHV advanced) and software (PCS v7.0+). Power off the tool and disconnect main power to avoid electrical hazards. Gather tools: DIN rail cutter (for EN 50022 rails), torque wrench (1.0–1.5 N·m), anti-static mat/wristband, and shielded Ethernet cables (CAT6a). Mount LAM 810-800081-022 on the DIN rail, ensuring ≥10 cm clearance from heat sources (e.g., RF generators) and ≥5 cm from adjacent modules. Connect power (24 VDC, locking M12) and signals: use twisted-pair cables for analog inputs to reduce noise, and verify Ethernet connectivity to LAM PCS before powering on.

Maintenance suggestions: Conduct bi-weekly checks of LAM 810-800081-022—inspect connectors for corrosion (clean with lint-free cloth + isopropyl alcohol) and verify AI fault prediction status via LAM PCS. Every 6 months, calibrate analog inputs using a NIST-traceable signal generator and update the module’s firmware via LAM PCS (to enhance AI algorithms). For troubleshooting: if Ethernet connectivity fails, check cable continuity and reset the module via the PCS; if AI alerts trigger, verify sensor/actuator wiring before replacing components. Keep a spare LAM 810-800081-022 for critical 7nm tools—replacement takes <15 minutes (DIN rail design), minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 3-year standard warranty for LAM 810-800081-022, covering defects in materials, workmanship, and AI functionality for 7nm–14nm semiconductor applications. This warranty includes free replacement of faulty modules, 24/7 global technical support (via phone/portal), and remote firmware updates to enhance performance. For advanced protection, customers can purchase the LAM Advanced Automation Support Plan, which extends coverage to 5 years and includes annual on-site calibration, priority engineering support (≤4-hour response time), and discounted spare parts (up to 40% off).

All LAM 810-800081-022 units undergo 240-hour pre-shipment testing—including environmental stress (temperature cycling, vibration), signal integrity, and AI fault prediction validation—to meet SEMI S3 standards. LAM also offers customized training for technicians, covering AI algorithm interpretation, advanced troubleshooting, and integration with 7nm tool clusters, ensuring customers fully leverage LAM 810-800081-022’s capabilities to optimize production efficiency.