Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-234640-312 |

| Manufacturer | LAM Research |

| Product category | High-Reliability Power Distribution Module (for Semiconductor Processing Systems) |

| Input Voltage Range | 100–240V AC (single-phase), 50/60 Hz |

| Output Channels | 12x isolated DC output channels (8x 24V DC, 4x 48V DC) |

| Output Current Capacity | 24V DC channels: 5A max per channel (30A total); 48V DC channels: 3A max per channel (12A total) |

| Isolation Voltage | 2.5kV AC (input to output); 1kV AC (output to output) |

| Efficiency | ≥92% (at full load, 230V AC input) |

| Interface Type | RS-485; 2x 60-pin terminal blocks (input power/outputs); 1x USB-C (configuration/monitoring) |

| Communication Protocol | Modbus RTU, LAM Proprietary PowerLink™ |

| Operating Temperature Range | 0°C to 50°C (non-condensing) |

| Relative Humidity Tolerance | 5% to 90% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 250mm × 320mm × 160mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (4U height); panel mounting (with optional heat-dissipating brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Protection Features | Over-voltage, over-current, short-circuit, over-temperature, and reverse-polarity protection |

| Monitoring Capabilities | Real-time voltage/current monitoring per channel; power consumption logging |

| Cooling Method | Forced-air cooling (2x variable-speed fans); passive heat sinks |

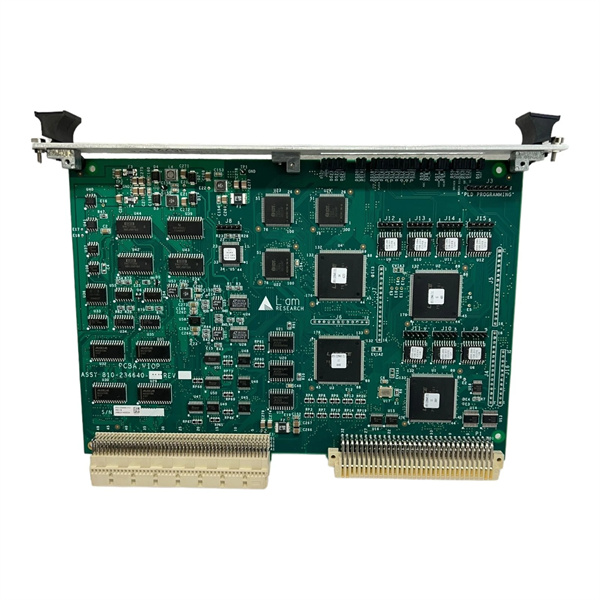

LAM 810-234640-312

Product Introduction

The 810-234640-312 is a high-reliability power distribution module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered to integrate with LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the “power backbone” for delivering stable, isolated DC power to critical subsystems.

As a core model in LAM’s Power Management Series, the 810-234640-312 is optimized for advanced semiconductor process nodes (down to 3nm), where uninterrupted, clean power is essential to preventing subsystem failures, maintaining process stability, and avoiding costly wafer scrappage. Its core function is to convert and distribute 100–240V AC input into 12 isolated DC outputs (8x 24V DC, 4x 48V DC), each with independent protection and monitoring. In automation systems, the 810-234640-312 acts as a critical intermediary between the facility’s power grid and sensitive hardware (e.g., 810-013872-105 motion control modules, 810-225420-002 DAQ modules), ensuring consistent power delivery even during grid fluctuations.

Core Advantages and Technical Highlights

Multi-Channel Isolation and Stability: The 810-234640-312 features 12 fully isolated output channels (2.5kV AC input-to-output isolation, 1kV AC output-to-output isolation)—a key advantage over non-isolated power modules. This isolation prevents cross-channel interference (e.g., voltage spikes from a motion motor affecting a DAQ module’s sensitive analog circuits), critical for 3nm/5nm processes where electrical noise can distort sensor data or disrupt motion precision. Each channel also maintains ±1% voltage regulation (even at 90% load), ensuring subsystems like the 810-013872-105 receive the stable power needed for ±0.001mm positioning accuracy.

Comprehensive Protection Mechanisms: Unlike basic power supplies, the 810-234640-312 includes multi-layer protection for both the module and connected subsystems: over-voltage protection (triggers at 115% of nominal output), over-current protection (adjustable per channel), short-circuit protection (instantaneous shutdown), over-temperature protection (activates at 70°C), and reverse-polarity protection. For example, if a 810-225420-002 DAQ module experiences a short circuit, the 810-234640-312 shuts down only the affected 24V channel—leaving other subsystems (e.g., temperature controllers) operational, minimizing downtime.

Real-Time Monitoring and Diagnostics: The 810-234640-312 provides granular real-time monitoring of voltage, current, and temperature for each output channel, accessible via RS-485 or USB-C. It also logs power consumption data (per channel, per hour) for up to 90 days, enabling fabs to identify inefficient subsystems or predict power-related issues. For instance, a gradual increase in current draw on a 48V channel powering a linear motor could indicate motor wear—allowing maintenance teams to replace the motor before it fails, avoiding unplanned production stops.

Semiconductor-Grade Durability and Efficiency: Built to comply with SEMI S2/S8/S14 standards, the 810-234640-312 features a corrosion-resistant aluminum housing (to withstand low-level process gas leaks) and conformal-coated circuit boards (to protect against ESD up to 15kV). Its ≥92% efficiency (at full load) reduces heat generation, while variable-speed fans and passive heat sinks maintain optimal operating temperature—extending the module’s mean time between failures (MTBF) to over 250,000 hours, far exceeding industry averages for power distribution units.

Typical Application Scenarios

The 810-234640-312 is indispensable in semiconductor fabs for power-critical operations, with two high-impact use cases: integrated subsystem power distribution in multi-chamber tools and legacy equipment power upgrades.

In multi-chamber tools (e.g., LAM’s Centura® Etch systems with 4 process chambers), the 810-234640-312 distributes power to a diverse set of subsystems: 24V DC channels power 810-225420-002 DAQ modules, temperature sensors, and chamber valves, while 48V DC channels power 810-013872-105 motion control modules and linear stage motors. Its channel isolation ensures that a power fluctuation in a motion motor does not disrupt DAQ data capture, critical for maintaining etch uniformity across 300mm wafers. Fabs using the 810-234640-312 report a 35% reduction in power-related subsystem failures, directly improving tool uptime.

In legacy equipment upgrades (e.g., pre-2018 Sym3® CVD systems), the 810-234640-312 replaces outdated, non-isolated power supplies that lack monitoring and protection. For example, a fab upgrading a legacy Sym3® system to support 5nm processes can install the 810-234640-312 to power new high-precision subsystems (e.g., advanced pressure sensors) while maintaining compatibility with existing hardware. The module’s real-time monitoring also allows the fab to integrate power data into LAM’s FabGuard® analytics platform, enabling predictive maintenance for the entire tool—extending its useful life by 5–7 years.

LAM 810-234640-312

Related Model Recommendations

LAM 810-234640-313: An upgraded variant of the 810-234640-312 with 16 output channels (10x 24V DC, 6x 48V DC) and higher total current capacity (40A for 24V, 18A for 48V), designed for large-scale tools (e.g., 8-chamber etch systems).

LAM 810-234640-311: A compact variant of the 810-234640-312 (3U rack height, 8 output channels) with reduced current capacity (3A per 24V channel, 2A per 48V channel), ideal for R&D labs or small-scale tools (e.g., single-chamber ALD systems).

LAM 810-234641-312: A redundant power distribution module that pairs with the 810-234640-312 for fault-tolerant systems (e.g., high-yield memory fabs), automatically switching to backup power if the primary module fails to prevent tool shutdown.

LAM 810-234639-312: A legacy replacement for LAM’s pre-2019 power modules (e.g., 810-234635-301), fully compatible with the 810-234640-312’s mounting, power inputs, and communication protocols.

LAM 810-234640-314: A high-temperature variant of the 810-234640-312 (operating range: -10°C to 60°C) with enhanced cooling (4x fans), designed for use near high-heat tools (e.g., MOCVD systems).

LAM 810-234642-312: A monitoring accessory module that adds Ethernet connectivity to the 810-234640-312, enabling remote power data access via LAM’s FabGuard® software (vs. RS-485 only).

LAM 810-234640-315: A low-voltage variant of the 810-234640-312 (outputs: 12x 12V DC, 5A per channel), optimized for powering sensitive sensors (e.g., optical wafer alignment sensors) in 3nm processes.

LAM 810-234643-312: A surge protection accessory module that connects between the AC input and 810-234640-312, shielding the module from facility power surges (common in fabs with high-power tools).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-234640-312, ensure the 19-inch rack or panel is clean (free of particulate matter) and the ambient temperature is within 0–50°C. Required tools include a torque wrench (3.5 N·m for rack mounting), multimeter (to verify AC input voltage), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect facility AC power before wiring; use color-coded cables (per LAM’s guidelines) for outputs to avoid misconnections to subsystems (e.g., 24V to 810-225420-002, 48V to 810-013872-105); and confirm the module’s ground connection (≥6AWG wire) is secure to prevent electrical hazards. Ensure at least 15cm clearance around the module for airflow (critical for fan cooling).

Maintenance Suggestions: For daily maintenance, check the 810-234640-312’s front-panel LED indicators (green = normal, amber = warning, red = fault) and verify channel voltage/current via the USB-C interface. Every 3 months, clean the fan filters with compressed air (≤50psi) to prevent overheating—clogged filters are a common cause of over-temperature faults. Every 12 months, update the module’s firmware via LAM’s PowerSuite™ software to access enhanced monitoring features and security patches. If a fault occurs (e.g., short-circuit on a 24V channel), first disconnect AC power, isolate the affected subsystem, and use the module’s diagnostic tool to confirm the fault source—replace damaged output fuses with LAM-approved fuses only (non-approved fuses may compromise safety). Avoid opening the module’s housing, as internal components are ESD-sensitive and require factory servicing.

Service and Guarantee Commitment

The 810-234640-312 comes with a 48-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and power distribution performance under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize tool downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers end-to-end technical support for the 810-234640-312, including 24/7 access to power management specialists via phone/email, remote diagnostics (via USB-C or RS-485), and on-site troubleshooting (available within 48 hours for global fabs). The module also includes free access to LAM’s PowerSuite™ software (for configuration, monitoring, and firmware updates) for 5 years post-purchase, ensuring compatibility with evolving subsystem power requirements.

To enhance reliability, LAM offers a Power Distribution Care Program for the 810-234640-312, which includes scheduled on-site inspections, proactive fan/filter replacement, and annual calibration of voltage monitoring circuits—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 810-234640-312’s quality and its dedication to supporting customers’ uninterrupted semiconductor manufacturing operations.