Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-225420-002 |

| Manufacturer | LAM Research |

| Product category | High-Speed Data Acquisition (DAQ) Module (for Semiconductor Processing Systems) |

| Analog Input Channels | 16x differential analog inputs (0–10V DC, 24-bit resolution) |

| Digital Input Channels | 8x digital status inputs (24V DC, sinking/sourcing) |

| Sampling Rate | Up to 1MSPS (mega-samples per second) per channel; 16MSPS aggregate |

| Data Storage Capacity | 32GB on-board SSD (expandable to 128GB via microSD slot) |

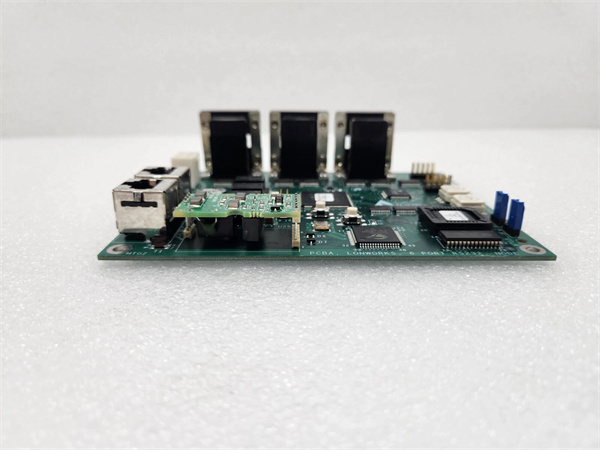

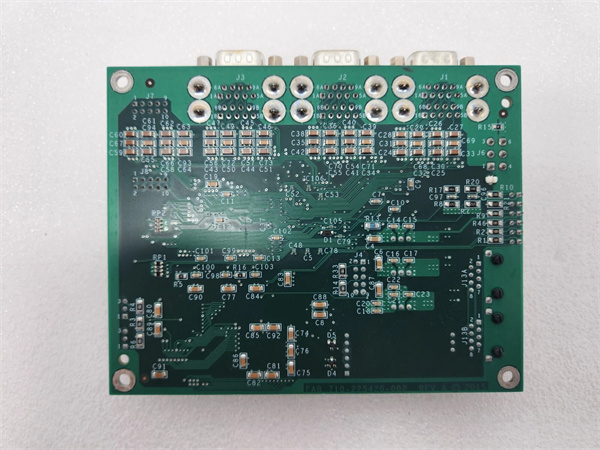

| Interface Type | Dual 10Gigabit Ethernet (SFP+); RS-485; 2x 48-pin terminal blocks (inputs/power); 1x USB-C (configuration) |

| Communication Protocol | UDP/IP (for high-speed data transfer), Modbus TCP/IP, LAM Proprietary DataLink™ |

| Operating Temperature Range | 0°C to 50°C (non-condensing) |

| Relative Humidity Tolerance | 5% to 90% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 230mm × 300mm × 140mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (3U height); DIN rail mounting (35mm standard, with adapter) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Power Consumption | 24V DC, 3.0A typical; 4.5A maximum (at full sampling rate) |

| Data Resolution | 24-bit (analog); 1-bit (digital) |

| Synchronization Support | PTP (Precision Time Protocol) v2.1 (±100ns accuracy) for multi-module sync |

LAM 810-225420-002

Product Introduction

The 810-225420-002 is a high-performance data acquisition (DAQ) module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered to integrate with LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the “data backbone” for capturing, storing, and transmitting critical process parameters in real time.

As a flagship model in LAM’s Data Acquisition Series, the 810-225420-002 is optimized for advanced semiconductor process nodes (down to 3nm), where granular, high-speed data monitoring is essential to identifying process drift, optimizing yield, and complying with industry traceability requirements. Its core function is to sample analog signals (e.g., temperature, pressure, gas flow) at up to 1MSPS per channel and digital status signals (e.g., valve positions, sensor alarms), then transmit this data to factory-wide control systems or local storage. In automation systems, the 810-225420-002 acts as a critical link between process hardware and data analytics tools, enabling real-time process adjustments and post-process root-cause analysis—key to maintaining consistency in high-volume wafer production.

Core Advantages and Technical Highlights

Ultra-High Sampling Speed and Resolution: The 810-225420-002 delivers a sampling rate of up to 1MSPS per analog channel (16MSPS aggregate) with 24-bit resolution—far exceeding the capabilities of standard DAQ modules (typically 100kSPS, 16-bit). This speed ensures that even transient process events (e.g., plasma ignition spikes, valve actuation delays) are captured with minimal latency, critical for troubleshooting intermittent defects in 3nm/5nm processes. The 24-bit resolution also provides sub-millivolt signal detection, allowing fabs to monitor subtle parameter shifts (e.g., 0.01V changes in pressure sensor output) that precede process failures.

High-Speed Data Transfer and Storage: Equipped with dual 10Gigabit Ethernet ports, the 810-225420-002 transmits data to central control systems at speeds up to 10Gbps—eliminating bottlenecks that plague slower DAQ modules. For scenarios where network connectivity is temporarily lost, its 32GB on-board SSD (expandable to 128GB) stores data locally, ensuring no critical information is lost. This “store-and-forward” capability is vital for fabs operating 24/7, where data gaps could compromise traceability or prevent timely fault diagnosis.

Multi-Module Synchronization: The 810-225420-002 supports PTP v2.1 synchronization, enabling precise alignment (±100ns accuracy) of data capture across multiple DAQ modules. This is critical for large-scale processing tools (e.g., multi-chamber etchers) where parameters from different chambers must be correlated to identify cross-chamber process interactions. Unlike modules relying on less accurate sync methods (e.g., RS-485 triggers), PTP ensures that time-stamped data from each 810-225420-002 module is aligned, simplifying analysis of system-wide performance.

Semiconductor-Grade Reliability: Built to comply with SEMI S2/S8/S14 standards, the 810-225420-002 features a ruggedized aluminum housing and conformal-coated circuit boards that resist corrosion from low-level process gas leaks (e.g., fluorine, chlorine) and protect against electrostatic discharge (ESD) up to 15kV. It also withstands vibration (10G peak, 10–500Hz) and temperature fluctuations (0–50°C), ensuring reliable operation in harsh fab environments. These design choices extend the module’s mean time between failures (MTBF) to over 200,000 hours.

Typical Application Scenarios

The 810-225420-002 is a foundational component in semiconductor fabs for data-driven process control, with two high-impact use cases: real-time plasma process monitoring and post-process yield analysis.

In real-time plasma process monitoring (e.g., LAM’s Centura® Etch systems), the 810-225420-002 samples analog signals from plasma impedance sensors, gas flow meters (e.g., paired with LAM 739-090783-001), and temperature controllers (e.g., LAM 839-330743-002) at 1MSPS. This high-speed data capture allows the system controller to detect plasma instability (e.g., sudden impedance spikes) within microseconds and adjust parameters (e.g., HV power via LAM 810-800082-043) to prevent wafer damage. Fabs using the 810-225420-002 report a 30% reduction in unplanned process interruptions, as transient issues are addressed before they escalate.

In post-process yield analysis, the 810-225420-002 stores historical process data (e.g., temperature profiles, pressure trends) on its on-board SSD, enabling engineers to correlate wafer defects (e.g., etch non-uniformity) with specific parameter deviations. For 3D NAND production, this traceability is critical—each wafer’s process data can be linked to its final yield, allowing teams to fine-tune recipes for maximum output. The module’s 10Gigabit Ethernet also enables seamless integration with LAM’s FabGuard® analytics platform, where machine learning algorithms use the 810-225420-002’s data to predict maintenance needs and optimize process parameters proactively.

LAM 810-225420-002

Related Model Recommendations

LAM 810-225420-003: An upgraded variant of the 810-225420-002 with 32 analog inputs (vs. 16) and 100GB on-board SSD, designed for multi-chamber tools (e.g., 8-chamber CVD systems) requiring extensive data capture.

LAM 810-225420-001: A cost-optimized variant of the 810-225420-002 with reduced sampling rate (500kSPS per channel) and 16GB SSD, ideal for R&D labs or low-volume specialty processes (e.g., MEMS fabrication).

LAM 810-225421-002: A redundant DAQ module that pairs with the 810-225420-002 for fault-tolerant systems (e.g., high-yield memory fabs), automatically taking over data capture if the primary module fails to avoid data loss.

LAM 810-225419-002: A legacy replacement for LAM’s pre-2018 DAQ modules (e.g., 810-225415-001), fully compatible with the 810-225420-002’s mounting, power, and protocol support.

LAM 810-225420-004: A wireless-enabled variant of the 810-225420-002 (Wi-Fi 6E, 5G), enabling data transfer in areas where Ethernet cabling is impractical (e.g., mobile wafer inspection tools).

LAM 810-225422-002: A data processing accessory module that offloads analytics from the 810-225420-002, running real-time trend analysis and anomaly detection to reduce network bandwidth usage.

LAM 810-225420-005: A high-temperature variant of the 810-225420-002 (operating range: -20°C to 70°C), designed for use near high-heat tools (e.g., MOCVD systems for compound semiconductors).

LAM 810-225423-002: A calibration accessory module that provides NIST-traceable voltage references for the 810-225420-002, simplifying on-site calibration of analog inputs and ensuring long-term data accuracy.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-225420-002, ensure the 19-inch rack or DIN rail is clean (free of particulate matter) and the ambient temperature is within 0–50°C. Required tools include a torque wrench (2.5 N·m for rack mounting, 0.8 N·m for DIN rail), multimeter (to verify 24V DC power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect power to the host system before wiring; use shielded twisted-pair cables for analog inputs to minimize electromagnetic interference (EMI); and confirm the module’s ground connection (≥8AWG wire) is secure to prevent ESD damage. For 10Gigabit Ethernet, use SFP+ transceivers and fiber cables rated for industrial use to ensure stable data transfer.

Maintenance Suggestions: For daily maintenance, check the 810-225420-002’s front-panel LED indicators (green = normal, amber = low storage/data warning, red = fault) and verify Ethernet link status via the module’s web interface. Every 3 months, back up on-board SSD data to a central server and check for firmware updates via LAM’s DataSuite™ software—install updates to access new features (e.g., enhanced PTP sync) and security patches. Every 12 months, perform a calibration check using LAM’s DAQCal™ tool (traceable to NIST standards) to verify analog input accuracy; replace shielded cables if signal noise exceeds 5mV. If a fault occurs (e.g., SSD failure), use the microSD slot to temporarily store data while replacing the SSD with a LAM-approved unit—non-approved SSDs may cause compatibility issues or data corruption.

Service and Guarantee Commitment

The 810-225420-002 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and data acquisition performance under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize data capture downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers end-to-end technical support for the 810-225420-002, including 24/7 access to DAQ specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours for global fabs). The module also includes free access to LAM’s DataSuite™ software (for configuration, data management, and firmware updates) for 5 years post-purchase, ensuring compatibility with evolving analytics platforms (e.g., LAM’s FabGuard® AI).

To enhance reliability, LAM offers a Data Acquisition Care Program for the 810-225420-002, which includes scheduled on-site inspections, proactive SSD replacement, and annual NIST-traceable calibration—tailored to the fab’s data retention requirements. This commitment reflects LAM’s confidence in the 810-225420-002’s quality and its dedication to supporting customers’ data-driven semiconductor manufacturing operations.