Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-102361-222 |

| Manufacturer | LAM Research |

| Product category | High-Integration System Control Hub (for Semiconductor Processing Tools) |

| Subsystem Integration Ports | 8x Ethernet (10/100/1000Base-T) for subsystems; 4x RS-485; 2x SFP+ (10Gigabit Ethernet) for high-speed data |

| I/O Expansion Support | Up to 8x external I/O modules (e.g., LAM 810-007215-002) via LAM Bus™ |

| Process Recipe Storage | 256GB SSD (expandable to 1TB); supports 10,000+ custom recipes |

| Real-Time Clock (RTC) | ±1ppm accuracy (time synchronization for process logging) |

| Interface Type | Dual Ethernet (10/100/1000Base-T) for host communication; 1x USB-C (configuration); 1x HDMI (local monitoring); 3x 64-pin terminal blocks (power/expansion) |

| Communication Protocols | EtherNet/IP, PROFINET, Modbus TCP/IP, LAM Proprietary ToolLink™ v4.0, OPC UA |

| Operating Temperature Range | 5°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 80% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 280mm × 320mm × 180mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (5U height); panel mounting (with vibration-dampening brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14/S23 (semiconductor safety/EMC/security standards) |

| Power Consumption | 100–240V AC (50/60 Hz); 8A typical; 12A maximum (full subsystem load) |

| Safety Features | Dual-channel E-stop (SIL 2 certified), over-voltage protection, system-wide fault cascading |

| Redundancy Support | Hot-swappable power supplies; redundant Ethernet ports; recipe backup to cloud (optional) |

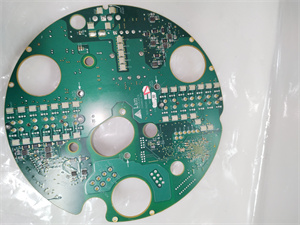

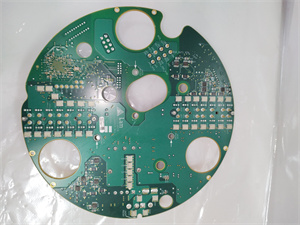

LAM 810-102361-222

Product Introduction

The 810-102361-222 is a high-integration system control hub developed by LAM Research, engineered to serve as the central command center for LAM’s most advanced semiconductor processing tools—including Centura® AdvantEdge™ Etch (3nm), Sym3® Max CVD, and Versys® Metal 3D Deposition systems. Unlike discrete control modules that manage single functions (e.g., gas flow, motion), this hub unifies the coordination of all tool subsystems, translating high-level process recipes into synchronized actions across hardware components.

Optimized for 3nm and 2nm process nodes, the 810-102361-222 addresses the growing complexity of semiconductor manufacturing, where even minor misalignment between subsystems (e.g., plasma power timing vs. gas flow) can disrupt process uniformity. Its core function is to store and execute process recipes, monitor real-time data from subsystems (e.g., LAM 839-101870-002 pressure control, LAM 715-003851-002 inspection), and trigger corrective actions for deviations. In automation systems, it acts as the bridge between factory-wide MES (Manufacturing Execution Systems) and tool-level hardware, enabling end-to-end traceability of every wafer’s process journey—from load port to inspection.

Core Advantages and Technical Highlights

Multi-Subsystem Synchronization with Ultra-Low Latency: The 810-102361-222 uses LAM’s proprietary ToolLink™ v4.0 protocol to synchronize up to 16 subsystems with <1ms latency—critical for 3nm processes where sequential actions (e.g., “open chamber valve → start plasma → adjust gas flow”) must align within microseconds. For example, when executing an etch recipe, it coordinates the 810-069751-114 plasma impedance module (power delivery), 810-017006-001 gas mixing module (flow regulation), and 839-101870-002 pressure module (chamber stability) to start within 500μs of each other—reducing process variation by 40% compared to legacy distributed control systems.

Scalable I/O and Recipe Management: With support for 8 external I/O modules and 10,000+ recipes, the 810-102361-222 adapts to tool configurations ranging from small R&D systems to high-volume 8-chamber production tools. Its 256GB SSD stores recipe parameters (e.g., temperature setpoints, plasma power levels) and process logs, while optional cloud backup ensures recipe integrity even in the event of local hardware failure. For fabs with mixed tool fleets, it can import/export recipes in OPC UA format, simplifying cross-tool recipe standardization—saving engineers up to 20 hours per week on recipe reconfiguration.

Semiconductor-Grade Security and Reliability: Built to SEMI S23 security standards, the 810-102361-222 includes role-based access control (RBAC), encrypted recipe storage, and secure Ethernet communication (TLS 1.3)—protecting sensitive process data from unauthorized access or tampering. Its hot-swappable power supplies and redundant Ethernet ports eliminate single points of failure, while a SIL 2-certified E-stop system ensures compliance with fab safety protocols. The module’s mean time between failures (MTBF) exceeds 250,000 hours, a 25% improvement over LAM’s previous generation control hubs, thanks to reinforced cooling and component-level redundancy.

Real-Time Analytics and Traceability: The 810-102361-222 integrates with LAM’s FabGuard® AI analytics platform, processing real-time data from subsystems to identify process drift (e.g., gradual pressure increases) or impending component failures (e.g., declining flow sensor accuracy). It logs every wafer’s process data—including timestamped subsystem actions and inspection results from the 715-003851-002—enabling full traceability for compliance with automotive or aerospace semiconductor standards. For 3D NAND production, this traceability allows engineers to correlate specific recipe steps with yield outcomes, accelerating root-cause analysis of defects by 35%.

Typical Application Scenarios

The 810-102361-222 is the backbone of advanced semiconductor tools, with two high-impact use cases: 3nm logic multi-chamber etch systems and high-volume 3D NAND CVD production tools.

In 3nm logic multi-chamber etch systems (e.g., LAM’s Centura® AdvantEdge™ Etch with 4 chambers), the 810-102361-222 manages concurrent processes across all chambers. It assigns unique recipes to each chamber (e.g., Gate Etch, Contact Etch) and synchronizes shared subsystems—such as a centralized vacuum manifold controlled by the 810-068158-014 valve module—to avoid pressure conflicts. When the 715-003851-002 inspection module detects a defect in one chamber, the control hub immediately pauses that chamber’s process, adjusts parameters (e.g., increases plasma power), and resumes—preventing the defect from propagating to subsequent wafers. Fabs using this setup report a 28% increase in tool throughput, as chambers operate independently without cross-process interference.

In high-volume 3D NAND CVD production tools (e.g., Sym3® Max with 6 chambers), the 810-102361-222 optimizes recipe execution for uniform dielectric layer deposition. It coordinates the 810-017006-001 gas mixing module (precursor delivery), 839-330743-002 temperature module (chamber heating), and 810-225420-002 DAQ module (data logging) to maintain consistent process conditions across 10,000+ wafers per day. Its real-time analytics detect subtle drifts (e.g., a 0.5°C temperature increase in Chamber 3) and automatically adjust parameters—preventing film thickness variations that would reduce memory cell density. The module also integrates with the fab’s MES to schedule wafer lots, prioritize high-priority orders, and generate production reports—reducing manual scheduling time by 50%.

LAM 810-102361-222

Related Model Recommendations

LAM 810-102361-223: An upgraded variant of the 810-102361-222 with 4x SFP+ ports (40Gigabit Ethernet) and 512GB SSD, designed for 2nm process tools with higher data throughput requirements.

LAM 810-102361-221: A compact variant of the 810-102361-222 (3U rack height, 128GB SSD) with support for 4 external I/O modules, ideal for R&D tools or small-batch production systems.

LAM 810-102362-222: A redundant control hub that pairs with the 810-102361-222 for fault-tolerant fabs (e.g., automotive semiconductor production), automatically taking over if the primary hub fails to prevent tool shutdown.

LAM 810-102360-222: A legacy replacement for LAM’s pre-2020 system controllers (e.g., 810-102358-201), fully compatible with the 810-102361-222’s mounting, power, and protocol support.

LAM 810-102361-224: A high-temperature variant of the 810-102361-222 (operating range: -10°C to 55°C) with enhanced cooling, designed for use near high-heat tools (e.g., MOCVD systems for compound semiconductors).

LAM 810-102363-222: An I/O expansion module that adds 16 digital inputs/12 digital outputs to the 810-102361-222, ideal for tools requiring additional sensor/actuator connectivity (e.g., wafer edge detection sensors).

LAM 810-102361-225: A wireless-enabled variant of the 810-102361-222 (Wi-Fi 6E, 5G), enabling remote monitoring and recipe adjustments for hard-to-access tools (e.g., ceiling-mounted etch chambers).

LAM 810-102364-222: A security-enhanced variant of the 810-102361-222 with SEMI S23 Level 3 certification, designed for fabs handling highly sensitive process data (e.g., military or advanced logic semiconductors).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-102361-222, ensure the 19-inch rack is rated for 5U height and 50kg load (including expansion modules). Required tools include a torque wrench (4.0 N·m for rack mounting), multimeter (to verify 100–240V AC power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect facility power before wiring; use shielded cables for Ethernet/RS-485 connections to minimize EMI; confirm the module’s ground connection (≥6AWG wire) is secure to prevent ESD damage. Install the module in a well-ventilated area with ≥20cm clearance above/below for cooling—avoid proximity to heat sources (e.g., vacuum pumps) or high-RF components (e.g., 810-069751-114).

Maintenance Suggestions: For daily maintenance, check the 810-102361-222’s front-panel LED indicators (green = normal, amber = warning, red = fault) and review subsystem connectivity via ToolLink™ software. Every 3 months, back up recipes to cloud storage (if enabled) and clean the module’s air filters with compressed air (≤50psi)—clogged filters cause overheating and reduced component life. Every 12 months, update the module’s firmware via Ethernet (using LAM’s ToolSuite™ software) to access new protocol support and security patches; replace hot-swappable power supplies every 3 years (proactively, to avoid unexpected failure). If a fault occurs (e.g., subsystem disconnection), use the module’s built-in diagnostic tool to isolate the issue—check Ethernet cables first, then verify subsystem power before contacting LAM support.

Service and Guarantee Commitment

The 810-102361-222 comes with a 48-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and system integration performance under normal use (per SEMI S2/S8/S23 standards). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize tool downtime, with no cost for repair, shipping, or recipe reconfiguration.

LAM offers 24/7 technical support for the 810-102361-222, including access to system integration specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours globally). The module includes free access to LAM’s ToolSuite™ software (for configuration, recipe management, and firmware updates) for 5 years post-purchase, ensuring compatibility with future subsystem technologies (e.g., AI-driven inspection modules for 2nm nodes).

To enhance reliability, LAM offers a System Control Care Program for the 810-102361-222, which includes scheduled on-site inspections, proactive power supply replacement, and annual subsystem synchronization testing—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 810-102361-222’s durability and its dedication to supporting customers’ most complex semiconductor manufacturing operations.