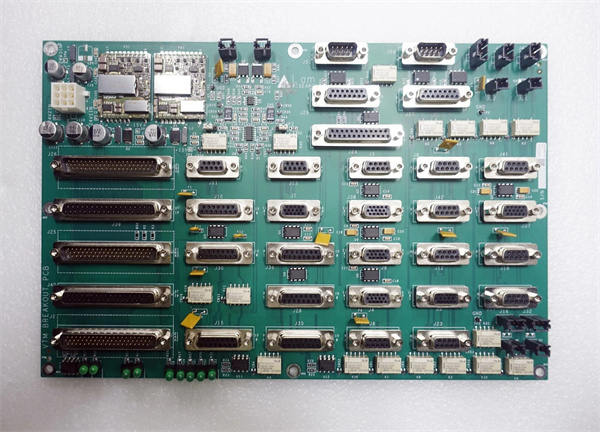

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-072907-005 |

| Manufacturer | LAM Research |

| Product category | Multi-Zone Thermal Management Control Module (for Semiconductor Processing Chambers) |

| Controlled Thermal Zones | 6 independent zones (configurable for heating/cooling; 3 heating-only, 3 hybrid) |

| Temperature Control Range | -20°C to 300°C (heating zones); 5°C to 150°C (cooling zones) |

| Temperature Control Accuracy | ±0.1°C (at 50–200°C, steady state); ±0.3°C (full range) |

| Heating Power Capacity | 500W per heating zone (3000W total); 24V DC/230V AC dual input support |

| Cooling Control Type | PWM (Pulse-Width Modulation) for chiller valve actuation (0–10V DC output) |

| Interface Type | Ethernet (10/100/1000Base-T); RS-485; 3x 32-pin terminal blocks (power/sensor signals); 1x USB-C (configuration); 6x RTD/thermocouple input ports |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary ThermalLink™ v2.3 |

| Operating Temperature Range | 10°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 80% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 250mm × 300mm × 140mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (4U height); panel mounting (with heat-dissipating brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC/thermal standards) |

| Power Consumption | 24V DC (logic): 1.0A typical; Heating zones: variable (up to 3000W max); Cooling: 0.5A (PWM output) |

| Sensor Compatibility | RTD (PT100, PT1000), Type K/J thermocouples (24-bit resolution) |

| Safety Features | Over-temperature shutdown (zone-specific thresholds), thermal runaway protection, short-circuit protection, sensor fault detection |

| Control Algorithms | Adaptive PID, fuzzy logic (for rapid temperature ramping); auto-tune function |

LAM 810-072907-005

Product Introduction

The 810-072907-005 is a high-precision multi-zone thermal management control module developed by LAM Research, engineered to address the critical thermal control needs of advanced semiconductor processing tools—including Centura® AdvantEdge™ Etch (3nm), Sym3® Max CVD, and Versys® Metal 3D Deposition systems. Unlike basic single-zone temperature controllers, this module manages up to 6 independent thermal zones (hybrid heating/cooling or heating-only) to maintain uniform temperatures across chamber components, wafer stages, and gas lines—an essential requirement for 3nm–2nm processes where thermal gradients directly impact device performance.

As a flagship model in LAM’s Thermal Control Series, the 810-072907-005 solves a key challenge in semiconductor manufacturing: balancing rapid temperature ramping (for process efficiency) with ultra-stable steady-state control (for process uniformity). Its core function is to monitor temperature via high-resolution sensors (RTDs/thermocouples), execute advanced control algorithms to adjust heating power or cooling valve actuation, and trigger protective actions if anomalies occur. In automation systems, it acts as a critical link between the 810-102361-222 system control hub and thermal hardware—synchronizing temperature adjustments with gas flow (via 810-017006-001) and pressure (via 839-101870-002) to maintain holistic process stability.

Core Advantages and Technical Highlights

Multi-Zone Precision and Flexibility: The 810-072907-005’s 6 independent zones (3 hybrid heating/cooling, 3 heating-only) enable targeted thermal control—critical for chambers with non-uniform heat loads (e.g., a wafer stage heated to 200°C while chamber walls are cooled to 50°C to prevent polymer deposition). Its ±0.1°C accuracy at 50–200°C (steady state) is achieved via 24-bit sensor resolution and adaptive PID algorithms that adjust parameters 100 times per second. For 3nm ALD processes, this precision ensures the wafer stage maintains a constant 150°C ±0.1°C, eliminating film thickness variations caused by thermal drift—reducing defect rates by up to 35% compared to single-zone controllers.

Rapid Ramping with Thermal Runaway Protection: Unlike legacy controllers that require 5–10 minutes to ramp from 25°C to 200°C, the 810-072907-005 uses fuzzy logic control to achieve ramping rates of up to 10°C/s (heating) and 5°C/s (cooling)—cutting process setup time by 40%. To prevent thermal runaway (a major safety risk), it includes zone-specific over-temperature thresholds (configurable via software) and a hardware-based emergency shutdown that activates if temperature exceeds the threshold by >5°C. For example, if a heating zone’s RTD fails, the module immediately cuts power to that zone within 100ms—preventing chamber damage or wafer scrappage.

Seamless Integration with Chillers and Heating Elements: The module supports both 24V DC and 230V AC heating elements (500W per zone) and uses PWM outputs (0–10V DC) to control chiller valves—enabling compatibility with LAM’s recommended thermal hardware (e.g., LAM 839-330743-002 heating elements, LAM 893-515602-002-paired chillers). Its ThermalLink™ v2.3 protocol synchronizes with chiller systems to adjust flow rates based on cooling demand—avoiding over-cooling (which wastes energy) or under-cooling (which causes temperature spikes). For CVD processes, this integration ensures the gas delivery line remains at 80°C ±0.2°C, preventing precursor condensation that would contaminate the chamber.

Comprehensive Diagnostics and Data Logging: The 810-072907-005 provides real-time monitoring of zone temperature, heating power, cooling valve position, and sensor health—all accessible via Ethernet or USB-C. It logs thermal data (time-stamped to ±1ms) for up to 90 days, enabling engineers to correlate temperature trends with process defects (e.g., a 0.5°C spike in zone 4 linked to etch non-uniformity). It also generates alerts for sensor drift (e.g., a PT100 reading deviating by >0.3°C from a reference) or cooling flow loss—allowing proactive maintenance before thermal issues impact production.

Typical Application Scenarios

The 810-072907-005 is indispensable in fabs for thermal-critical processes, with two high-impact use cases: multi-zone chamber thermal control for 3nm plasma etching and precision wafer stage heating for 2nm ALD.

In 3nm plasma etching (e.g., LAM’s Centura® AdvantEdge™ Etch), the 810-072907-005 manages 6 zones: 2 heating zones for the wafer stage (maintained at 180°C ±0.1°C to enhance etch selectivity), 2 cooling zones for the chamber walls (50°C ±0.2°C to prevent polymer buildup), and 2 heating zones for the gas injectors (100°C ±0.1°C to keep etch gases in vapor phase). It synchronizes with the 810-069751-114 plasma impedance module: when plasma power increases (generating more heat), the module boosts cooling to the chamber walls and adjusts the wafer stage heater to maintain target temperature—preventing etch rate drift. Fabs using this setup report a 28% increase in etch uniformity across 300mm wafers.

In 2nm ALD (e.g., Sym3® ALD for high-k dielectric layers), the 810-072907-005 controls a hybrid zone for the wafer stage (heating to 220°C, cooling to 150°C between precursor pulses) and 2 heating zones for the precursor delivery lines (80°C ±0.1°C to prevent condensation). Its rapid ramping (10°C/s) enables fast transitions between ALD pulses, reducing cycle time per layer by 15% compared to legacy controllers. The module’s sensor fault detection also prevents catastrophic failures: if a thermocouple in the delivery line fails, the module shuts down the precursor flow and alerts the operator—avoiding chamber contamination that would require hours of cleaning.

LAM 810-072907-005

Related Model Recommendations

LAM 810-072907-006: An upgraded variant of the 810-072907-005 with 8 thermal zones (4 hybrid, 4 heating-only) and extended temperature range (-40°C to 400°C), designed for UHV processes like molecular beam epitaxy (MBE).

LAM 810-072907-004: A compact variant of the 810-072907-005 (3U rack height, 4 zones: 2 hybrid, 2 heating-only) with reduced power capacity (300W per zone), ideal for R&D labs or small-scale ALD tools.

LAM 810-072908-005: A redundant thermal control module that pairs with the 810-072907-005 for fault-tolerant fabs (e.g., automotive semiconductor production), automatically taking over if the primary module fails to prevent thermal excursions.

LAM 810-072906-005: A legacy replacement for LAM’s pre-2020 thermal controllers (e.g., 810-072905-001), fully compatible with the 810-072907-005’s mounting, power, and protocol support.

LAM 810-072907-007: A high-temperature variant of the 810-072907-005 (heating range up to 500°C), designed for high-temperature processes like metal organic CVD (MOCVD) for compound semiconductors.

LAM 810-072909-005: A thermal calibration accessory module that provides NIST-traceable temperature references (-20°C to 300°C) for the 810-072907-005, simplifying on-site sensor calibration.

LAM 810-072907-008: A wireless-enabled variant of the 810-072907-005 (Wi-Fi 6E, 5G), enabling remote monitoring of thermal zones for hard-to-access tools (e.g., ceiling-mounted CVD chambers).

LAM 810-072910-005: A thermal mapping accessory module that adds 4 additional RTD inputs to the 810-072907-005, enabling detailed temperature profiling of large wafer stages (e.g., 450mm wafers).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-072907-005, ensure the 19-inch rack is rated for 4U height and 40kg load (including wiring), and the ambient temperature is 10–45°C. Required tools include a torque wrench (3.0 N·m for rack mounting), multimeter (to verify 24V DC/230V AC power), ESD-safe gloves/wristbands, precision thermometer (for calibration), and a laptop (for USB-C configuration). Safety precautions: Disconnect power to heating/cooling hardware before wiring; use shielded cables for sensor signals to minimize EMI (critical for ±0.1°C accuracy); confirm the module’s ground connection (≥10AWG wire) is secure to prevent electrical hazards; and label zone wiring clearly to avoid cross-connection (which causes thermal errors). Avoid mounting near heat sources (e.g., vacuum pumps) or cooling vents to prevent ambient temperature interference.

Maintenance Suggestions: For daily maintenance, check the 810-072907-005’s front-panel LED indicators (green = normal, amber = zone warning, red = critical fault) and review zone temperatures via ThermalLink™ software. Every 3 months, inspect terminal blocks for loose wiring (retorque to 0.8 N·m) and clean the module’s heat sinks with compressed air (≤50psi) to prevent overheating. Every 6 months, calibrate sensors using the LAM 810-072909-005 accessory to maintain ±0.1°C accuracy; replace RTD/thermocouple cables if signal noise exceeds 0.05°C. If a fault occurs (e.g., over-temperature), first shut down the affected thermal zone, isolate the module from power, and use the diagnostic log to identify the cause (e.g., faulty heater, clogged chiller line)—never bypass safety features (e.g., thermal runaway protection) to resume operation.

Service and Guarantee Commitment

The 810-072907-005 comes with a 48-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and thermal control performance under normal use (per SEMI S2/S8 standards). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize thermal system downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers 24/7 technical support for the 810-072907-005, including access to thermal control specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours globally). The module includes free access to LAM’s ThermalSuite™ software (for configuration, calibration, and firmware updates) for 5 years post-purchase, ensuring compatibility with new thermal hardware (e.g., next-gen high-temperature heaters for 2nm nodes).

To enhance reliability, LAM offers a Thermal Management Care Program for the 810-072907-005, which includes scheduled on-site thermal profiling, proactive sensor/cable replacement, and annual calibration—tailored to the fab’s production schedule (e.g., monthly ALD tool maintenance). This commitment reflects LAM’s confidence in the 810-072907-005’s quality and its dedication to supporting customers’ thermal-critical semiconductor manufacturing operations.