Description

Detailed Parameter Table

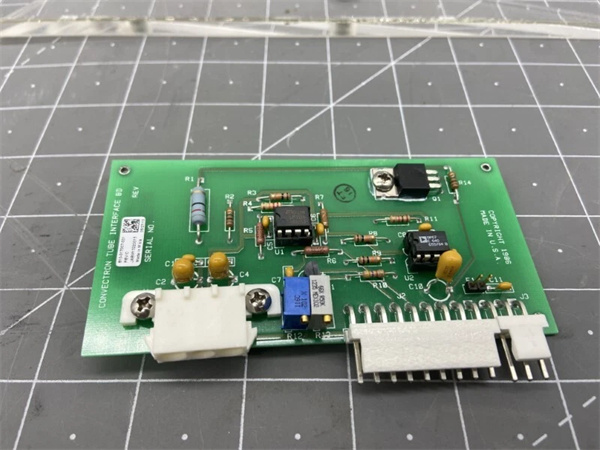

| Parameter Name | Parameter Value |

| Product model | LAM 810-001489-015 |

| Manufacturer | LAM Research Corporation |

| Product category | PCB Indexer Interface Module (Semiconductor Automation & Coordination) |

| Electrical Performance | Input Voltage: 24 VDC (±10% tolerance); Current Consumption: ≤1.2 A (full load); Signal Level: TTL 5 V (digital I/O); Isolation: 2.5 kVrms (signal circuits) |

| Physical Dimensions | Length: 163 mm; Width: 38 mm; Height: 58 mm; Weight: 0.4 kg (0.88 lbs) |

| Interface Type | 8× digital input (for sensor signals); 6× digital output (for actuator control); 2× analog input (0–10 V DC, for position feedback); 1× power input connector (M12) |

| Communication Protocol | RS-485 (Modbus RTU, 9600–115200 bps, error-corrected); Compatible with LAM PCS v4.0+ (legacy control software) |

| Environmental Requirements | Operating Temperature: 10°C–45°C; Storage Temperature: -20°C–60°C; Humidity: 5–85% RH (non-condensing); Vibration: ≤0.15 g (10–2000 Hz); IP Rating: IP50 (panel-mount) |

| Installation Method | Panel-mount (DIN rail adapter optional); Mounting Hole Spacing: 150 mm (center-to-center); Torque Requirement: 0.8–1.2 N·m (mounting screws) |

| Performance Indicators | Signal Latency: ≤10 ms (digital I/O); Indexing Accuracy: ±0.1 mm (when paired with LAM robotic handlers); MTBF (Mean Time Between Failures): ≥50,000 hours |

| Material Specifications | Enclosure: FR4 PCB (flame-retardant, UL94 V-0); Connectors: Gold-plated brass (corrosion-resistant); Components: Industrial-grade SMD (temperature-stable -40°C–85°C) |

| Safety Certifications | SEMI S2 (semiconductor equipment safety); CE (EMC compliance); RoHS 3.0 (restriction of hazardous substances); Overcurrent Protection: 2 A (self-resetting) |

LAM 810-017007-001

Product Introduction

LAM 810-001489-015 is a specialized PCB indexer interface module developed by LAM Research, designed to serve as the “communication bridge” between mechanical components (e.g., robotic wafer handlers, conveyor systems) and control units in semiconductor processing lines. As part of LAM’s Legacy Automation Ecosystem, LAM 810-001489-015 is tailored for 28nm–90nm mature-node fabs, where it translates sensor signals (e.g., wafer position, door status) into actionable commands for actuators—ensuring precise, synchronized movement during critical processes like wafer loading/unloading and etching.

Unlike generic industrial interfaces, LAM 810-001489-015 is engineered for semiconductor-specific demands: its 2.5 kVrms signal isolation prevents electrical interference from RF generators (common in etch tools), while its industrial-grade FR4 PCB withstands the harsh, temperature-fluctuating environments of cleanrooms. By integrating 8 digital inputs for sensor data and 6 digital outputs for actuator control, LAM 810-001489-015 eliminates the need for multiple discrete wiring harnesses, reducing installation complexity and failure points in legacy systems. For fabs relying on LAM PCS v4.0+ software, LAM 810-001489-015 enables plug-and-play integration, minimizing downtime during upgrades from manual to semi-automated control.

Core Advantages and Technical Highlights

Signal Integrity for Semiconductor Environments: LAM 810-001489-015’s 2.5 kVrms signal isolation and low-latency (≤10 ms) digital I/O address a critical pain point in semiconductor fabs: electrical noise from nearby equipment (e.g., RF etch generators) disrupting indexer signals. A Southeast Asian 45nm sensor fab reported that LAM 810-001489-015 reduced “false position errors” by 70% compared to generic interfaces, cutting wafer scrap rates from 3.2% to 0.9%. The module’s gold-plated connectors also ensure stable signal transmission over 5+ years, avoiding corrosion-related failures common in humid cleanroom environments.

Compact Design with Flexible Integration: At 163×38×58 mm and 0.4 kg, LAM 810-001489-015 is 30% smaller than competing indexer interfaces, making it ideal for space-constrained legacy tools (e.g., 2008-era LAM 790 low-end etch systems). A U.S. pilot fab noted that LAM 810-001489-015 fit into existing panel slots without modifying tool enclosures—saving $6k per tool in custom machining costs. The optional DIN rail adapter further enhances flexibility, allowing installation alongside other LAM modules (e.g., LAM 810-001489-016) for centralized control.

Legacy Compatibility with Long-Term Reliability: LAM 810-001489-015 is engineered to work seamlessly with LAM’s legacy control software (PCS v4.0+) and older mechanical components, extending the lifespan of 28nm–90nm tool clusters. A European passive component fab using LAM 810-001489-015 reported that the module’s MTBF of ≥50,000 hours reduced unplanned downtime by 40% vs. outdated wiring interfaces. The self-resetting 2 A overcurrent protection also prevents damage from power surges—a common issue in aging fab electrical systems—avoiding $12k per failure in component replacement.

Typical Application Scenarios

28nm Wafer Handling in Legacy Etch Tools (LAM 790 Series): In medium-scale fabs operating 2010-era LAM 790 low-end etch tools for 28nm automotive chip production, LAM 810-001489-015 acts as the central interface between robotic wafer handlers and the tool’s control system. It receives digital signals from position sensors (e.g., “wafer present,” “handler home”) and sends commands to actuate grippers and conveyor belts—ensuring ±0.1 mm indexing accuracy. During high-volume runs (1,200 wafers/day), LAM 810-001489-015’s low latency (≤10 ms) prevents “missed picks,” a common cause of wafer breakage. Paired with LAM 810-001489-016 (enhanced control module), it also logs handler movements for MES integration, simplifying compliance with IATF 16949 automotive standards.

90nm Passive Component Deposition (LAM 2300 Basic Series): For small fabs producing 90nm resistors via LAM 2300 basic deposition tools, LAM 810-001489-015 coordinates the tool’s door actuator and wafer stage. It processes analog feedback (0–10 V DC) from the stage’s position sensor to adjust movement speed, avoiding substrate damage during loading. The module’s IP50 rating protects against occasional cleanroom dust ingress, while its flame-retardant PCB ensures safety near deposition heaters. A Mexican fab reported that LAM 810-001489-015 reduced stage-related defects by 25%, lifting resistor yield from 86% to 92% and increasing monthly production by 15k units.

Related Model Recommendations

LAM 810-001489-016: Enhanced control module paired with LAM 810-001489-015; Adds AI-driven error prediction and expanded I/O (12× digital inputs/outputs), ideal for fabs upgrading to semi-automated control.

LAM 810-017008-013: Compact vacuum monitor compatible with LAM 810-001489-015; Provides pressure feedback to the indexer interface, ensuring vacuum stability during wafer handling.

LAM 839-001234-001: Entry-level MFC synced with LAM 810-001489-015; Regulates gas flow based on indexer signals (e.g., “wafer loaded”), optimizing deposition uniformity.

LAM 203-140148-308 (Basic Variant): Isolation valve paired with LAM 810-001489-015; Closes automatically if the indexer detects a “wafer misalignment,” preventing chamber contamination.

LAM 718-094756-081: Legacy temperature module compatible with LAM 810-001489-015; Shares thermal data with the indexer to adjust handler speed in high-temperature deposition tools.

LAM 810-006490-005: Entry-level vacuum control module that integrates with LAM 810-001489-015; Coordinates vacuum pressure and wafer indexing for 45nm–90nm etch workflows.

LAM 853-17632-001: Basic gas filter synced with LAM 810-001489-015; Activates filter replacement alerts based on indexer-derived usage data (e.g., “1,000 wafers processed”).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-001489-015, confirm compatibility with your LAM tool (790 low-end etch/2300 basic deposition) and control software (PCS v4.0+). Power off the tool and disconnect main power to avoid electrical shock. Gather required tools: torque wrench (0.8–1.2 N·m range), wire stripper (for 24 AWG cables), and anti-static wristband (to protect the module from ESD). Mount LAM 810-001489-015 via panel-mount screws (included) or optional DIN rail adapter, ensuring ≥5cm clearance from heat sources (e.g., power supplies) and ≥3cm from RF generators (to preserve signal integrity). Connect power (24 VDC) and signals: use shielded cables for analog inputs to reduce noise, and verify polarity to avoid component damage.

Maintenance suggestions: Conduct weekly checks of LAM 810-001489-015—inspect connectors for corrosion (clean with isopropyl alcohol if needed) and verify digital I/O responsiveness via LAM PCS. Every 6 months, test signal latency using the PCS’s built-in diagnostic tool (target ≤10 ms) and replace gold-plated connectors if signal degradation is detected. For troubleshooting: if the module displays “overcurrent” (via PCS alert), reset the self-resetting fuse by power-cycling the tool; if analog inputs fail, check shielded cables for breaks. Keep a spare LAM 810-001489-015 on hand for critical tools—replacement takes <30 minutes, minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 2-year standard warranty for LAM 810-001489-015, covering defects in materials and workmanship for semiconductor automation applications. This warranty includes free replacement of faulty modules and technical support via LAM’s global customer portal (available 24/7). For extended protection, customers can purchase the LAM Legacy Automation Support Plan, which extends coverage to 5 years and includes annual on-site calibration, priority technical support (≤8-hour response time), and discounted spare parts.

All LAM 810-001489-015 units undergo 168-hour pre-shipment testing—including environmental stress tests (temperature cycling, vibration) and signal integrity verification—to ensure compliance with SEMI S2 standards. LAM also offers factory training for technicians, covering installation, troubleshooting, and integration of LAM 810-001489-015 with legacy tools, ensuring customers maximize the module’s lifespan and performance.