Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-017006-001 |

| Manufacturer | LAM Research |

| Product category | Process Gas Mixing Control Module (for Semiconductor Wafer Processing) |

| Gas Input Channels | 6 independent gas inlets (compatible with inert, reactive, and precursor gases) |

| Mixing Ratio Range | 0.1% to 99.9% per gas (configurable in 0.01% increments) |

| Flow Rate Range per Channel | 1 sccm to 1000 sccm (standard cubic centimeters per minute) |

| Mixing Accuracy | ±0.2% of set ratio (at 25°C, 1 atm; 10–100% flow range) |

| Interface Type | Ethernet (10/100/1000Base-T); RS-485; 3x 24-pin terminal blocks (power/gas signals); 1x USB-C (configuration); 6x gas inlet ports (1/4-inch VCR fittings) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary GasMixLink™ v2.1 |

| Operating Temperature Range | 10°C to 40°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 75% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 220mm × 280mm × 120mm (excluding fittings/connectors) |

| Installation Method | DIN rail mounting (35mm standard); panel mounting (with anti-vibration brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC/gas compatibility) |

| Power Consumption | 24V DC, 1.2A typical; 1.8A maximum (all channels active) |

| Gas Compatibility | Inert (Ar, N₂), reactive (O₂, CF₄, Cl₂), precursors (TEOS, TiCl₄); compatible with corrosive gas lines |

| Safety Features | Over-pressure protection (10 bar max inlet), gas leak detection (via pressure drop), emergency gas shutoff |

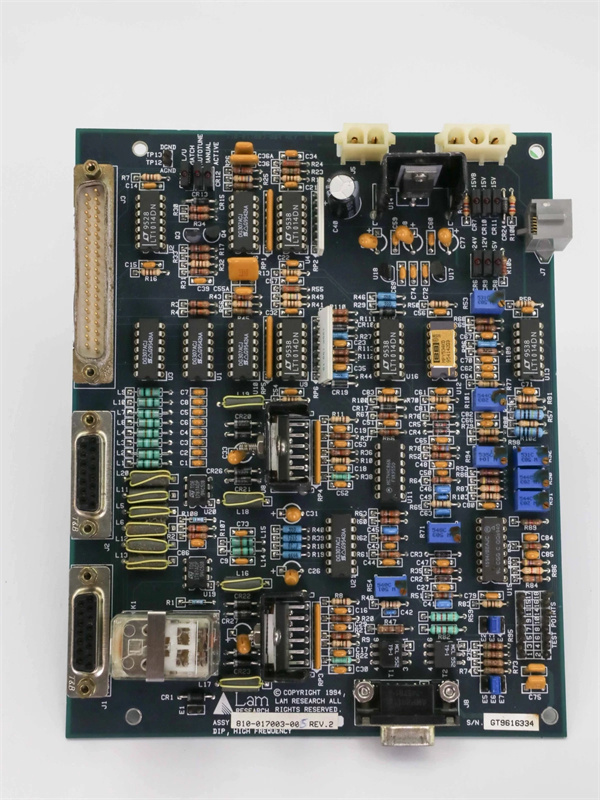

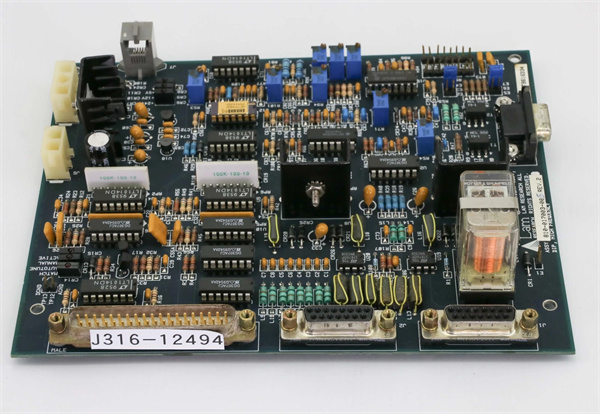

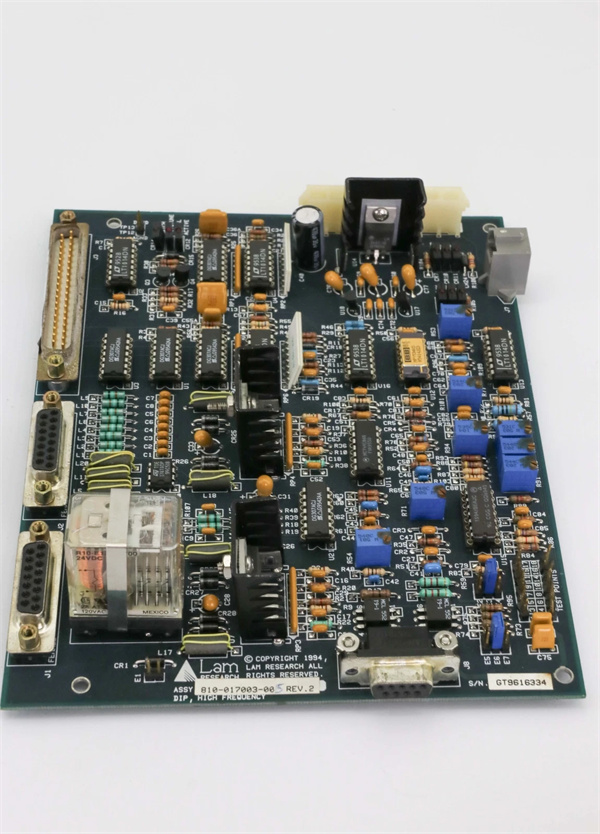

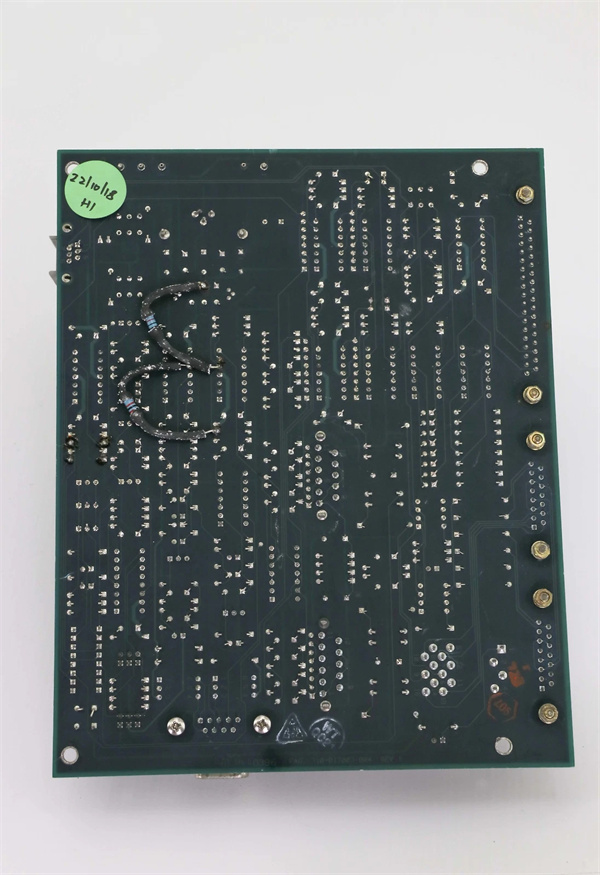

LAM 810-017003-005

Product Introduction

The 810-017006-001 is a high-precision process gas mixing control module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Explicitly engineered for integration into LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the “gas blending hub” for semiconductor fabrication, ensuring consistent, repeatable mixtures of multiple process gases.

As a flagship model in LAM’s Gas Management Series, the 810-017006-001 is optimized for advanced semiconductor process nodes (down to 3nm), where even 0.1% deviations in gas mixing ratios can disrupt plasma stability, alter etch profiles, or cause thin-film defects. Its core function is to regulate the flow of up to 6 individual gases, blend them at user-defined ratios (0.1–99.9% per gas), and deliver the homogeneous mixture to the process chamber. In automation systems, the 810-017006-001 acts as a critical link between gas supply systems and subsystems like the 839-101870-002 pressure control module and 810-069751-114 plasma impedance module—synchronizing gas mixture adjustments with pressure and plasma power to maintain optimal process conditions.

Core Advantages and Technical Highlights

Ultra-Precise Mixing Ratio Control: The 810-017006-001 delivers industry-leading mixing accuracy of ±0.2% of the set ratio, enabled by 24-bit flow sensors per channel and a proprietary closed-loop feedback system that adjusts flow rates 500 times per second. Unlike basic gas mixers (±1% accuracy), this precision ensures that critical mixtures—such as 95% Ar / 5% O₂ for plasma cleaning or 0.5% TEOS / 99.5% N₂ for CVD—remain consistent across thousands of wafers. For 3nm logic etching, this stability reduces etch rate variation by up to 30% compared to legacy mixers, directly improving device performance uniformity.

Multi-Gas Versatility and Corrosion Resistance: With 6 independent gas input channels, the 810-017006-001 supports a wide range of gas types—from inert carriers (Ar, N₂) to highly reactive etch gases (CF₄, Cl₂) and vapor-phase precursors (TEOS). Its internal wetted parts are coated with a Hastelloy® C-276 alloy (resistant to fluorine, chlorine, and other corrosive species), while inlet ports feature PTFE gaskets to prevent gas contamination. This design eliminates the need for dedicated mixers for different gas groups, reducing tool footprint and simplifying maintenance—critical for space-constrained cleanrooms.

Real-Time Monitoring and Leak Detection: The 810-017006-001 provides granular real-time data on individual gas flow rates, mixing ratios, and inlet pressure via Ethernet or USB-C. It also includes built-in gas leak detection: if a pressure drop is detected in a gas line (indicating a leak), the module immediately triggers an emergency shutoff for that channel and sends an alert to the main controller—preventing hazardous gas releases and protecting chamber hardware. For example, a leak in a CF₄ line would trigger a shutdown within 500ms, minimizing safety risks and avoiding process contamination.

Seamless System Synchronization: Equipped with LAM’s GasMixLink™ v2.1 protocol, the 810-017006-001 synchronizes gas mixing with other critical subsystems. When the 839-101870-002 pressure module adjusts chamber pressure, the 810-017006-001 automatically scales gas flow rates to maintain the target mixing ratio—eliminating manual adjustments and reducing recipe setup time by 25%. It also integrates with the 810-225420-002 data acquisition module to log mixing data for 90 days, enabling post-process analysis of defects linked to gas ratio drift.

Typical Application Scenarios

The 810-017006-001 is indispensable in fabs for gas-critical processes, with two high-impact use cases: plasma etching for 3nm logic devices and plasma-enhanced CVD (PECVD) for 3D NAND thin films.

In 3nm logic plasma etching (e.g., LAM’s Centura® AdvantEdge™ Etch), the 810-017006-001 blends a complex mixture of 4 gases: 60% Ar (plasma carrier), 25% CF₄ (etchant), 10% O₂ (polymer removal), and 5% CH₂F₂ (profile control). Its ±0.2% mixing accuracy ensures the etch plasma maintains consistent chemistry, preventing undercutting of gate structures or line-edge roughness—two critical defects in 3nm devices. The module’s leak detection also safeguards against CF₄ leaks, which could corrode chamber components or pose safety risks. Fabs using the 810-017006-001 report a 28% reduction in etch-related yield loss compared to legacy mixers.

In 3D NAND PECVD (e.g., Sym3® PECVD for dielectric layer deposition), the 810-017006-001 mixes 0.8% TEOS (precursor) with 99.2% N₂ (carrier gas) to form a uniform SiO₂ layer. Its 0.01% ratio adjustability allows engineers to fine-tune the precursor concentration, ensuring the dielectric layer meets the 5nm thickness target with ±2% uniformity. The module synchronizes with the 810-069751-114 plasma impedance module: when plasma power is adjusted, the 810-017006-001 tweaks the TEOS ratio to compensate for power-induced changes in precursor decomposition—maintaining film quality across the wafer. This coordination is critical for 3D NAND, where dielectric layer defects can cause cell-to-cell leakage and reduce memory density.

LAM 810-017003-005

Related Model Recommendations

LAM 810-017006-002: An upgraded variant of the 810-017006-001 with 8 gas input channels (vs. 6) and extended flow range (0.5–2000 sccm), designed for high-throughput 2nm process tools requiring complex gas mixtures.

LAM 810-017006-000: A compact variant of the 810-017006-001 (4 gas channels, 2U rack height) with reduced flow range (1–500 sccm), ideal for R&D labs or small-scale tools (e.g., single-chamber ALD systems).

LAM 810-017007-001: A redundant gas mixing module that pairs with the 810-017006-001 for fault-tolerant fabs (e.g., high-yield memory production), automatically taking over if the primary module fails to prevent gas mixture disruption.

LAM 810-017005-001: A legacy replacement for LAM’s pre-2020 gas mixers (e.g., 810-017002-001), fully compatible with the 810-017006-001’s mounting, power, and protocol support.

LAM 810-017006-003: A heated variant of the 810-017006-001 (temperature range: 25–80°C), preventing condensation of high-vapor-pressure precursors (e.g., TiCl₄) in ALD processes.

LAM 810-017008-001: A gas filter accessory module that integrates with the 810-017006-001, featuring 0.1μm PTFE filters per channel to remove particulate contaminants from gas lines.

LAM 810-017006-004: A wireless-enabled variant of the 810-017006-001 (Wi-Fi 6, Bluetooth 5.2), enabling remote monitoring and ratio adjustments for hard-to-access cleanroom tools.

LAM 810-017009-001: A calibration accessory module that provides NIST-traceable gas flow references for the 810-017006-001, simplifying on-site mixing accuracy verification.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-017006-001, ensure the mounting surface is clean (Class 1 cleanroom compliant) and ambient temperature is 10–40°C. Required tools include a torque wrench (0.8 N·m for DIN rail mounting), gas leak detector (He-based), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Purge all gas lines with inert gas (N₂) for 10 minutes before connecting to the module to remove air/moisture; use only LAM-approved 1/4-inch VCR fittings (compatible with corrosive gases) to prevent leaks; confirm inline filters (0.1μm) are installed upstream of each gas inlet to protect internal sensors. Avoid mounting near heat sources (e.g., chamber heaters) to prevent temperature-induced flow drift.

Maintenance Suggestions: For daily maintenance, check the 810-017006-001’s front-panel LED indicators (green = normal, amber = low flow, red = leak/fault) and verify mixing ratios via GasMixLink™ software. Every 3 months, perform a leak test on all gas connections using a He detector (leak rate threshold: <1×10⁻⁹ atm·cc/s); replace PTFE gaskets if leaks are detected. Every 12 months, calibrate the module using LAM’s GasMixCal™ tool (NIST-traceable) to maintain ±0.2% mixing accuracy; clean sensor housings with compressed inert gas (Ar, <30 psi) to remove residual gas deposits. If a fault occurs (e.g., over-pressure), first isolate the affected gas line, shut off the inlet valve, and use the module’s diagnostic log to identify the cause—never disassemble gas-carrying components without proper safety training (risk of corrosive gas exposure).

Service and Guarantee Commitment

The 810-017006-001 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and gas mixing accuracy under normal use (per SEMI S2/S8 standards). If the module fails within the warranty period, LAM provides a “swap-and-calibrate” service—delivering a pre-calibrated replacement unit within 48 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers 24/7 technical support for the 810-017006-001, including access to gas management specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 72 hours globally). The module includes free access to LAM’s GasMixSuite™ software (for configuration, calibration, and firmware updates) for 5 years post-purchase, ensuring compatibility with new gas types (e.g., next-gen ALD precursors for 2nm nodes).

To enhance reliability, LAM offers a Gas Mixing Care Program for the 810-017006-001, which includes scheduled on-site leak testing, proactive filter/gasket replacement, and annual NIST-traceable calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 810-017006-001’s quality and its dedication to supporting customers’ gas-critical semiconductor manufacturing operations.