Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-013872-105 |

| Manufacturer | LAM Research |

| Product category | Precision Motion Control Module (for Semiconductor Processing Actuators/Robots) |

| Controlled Axis Count | 4 independent axes (supports stepper, servo, and linear motors) |

| Motor Compatibility | Stepper motors (up to 8A peak current); Servo motors (up to 6A continuous current); Linear motors (up to 10A peak) |

| Positioning Accuracy | ±0.001mm (with encoder feedback); ±0.01mm (open-loop mode) |

| Speed Range | 0.1mm/s to 500mm/s (linear motion); 0.1 rpm to 3000 rpm (rotary motion) |

| Interface Type | Ethernet (10/100/1000Base-T); RS-485; 2x 50-pin terminal blocks (power/motor signals); 1x USB-C (configuration); 4x encoder input ports (A/B/Z phase) |

| Communication Protocol | EtherCAT (for real-time motion sync), Modbus TCP/IP, LAM Proprietary MotionLink™ |

| Operating Temperature Range | 5°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 80% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 240mm × 320mm × 150mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (4U height); panel mounting (with optional vibration-dampening brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Power Consumption | 24V DC (logic), 48–72V DC (motor power); 5A typical (logic), 20A max (motor) |

| Feedback Support | Incremental encoders (up to 1MHz), absolute encoders (SSI, BiSS-C), linear scales |

| Safety Features | Over-current protection, over-temperature shutdown, emergency stop (E-stop) input, position limit switches |

LAM 810-013872-105

Product Introduction

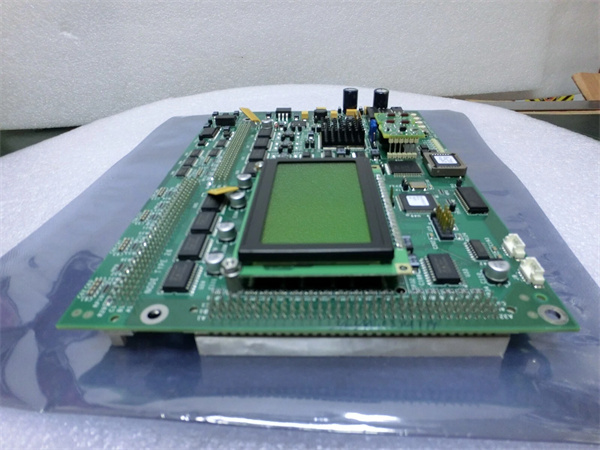

The 810-013872-105 is a high-precision motion control module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered to integrate with LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module serves as the “motion brain” for regulating critical mechanical components, such as wafer handling robots, process stage actuators, and chamber isolation shutters.

As a core model in LAM’s Motion Control Series, the 810-013872-105 is optimized for advanced semiconductor process nodes (down to 3nm), where sub-millimeter positioning accuracy is essential to preventing wafer damage, ensuring uniform process exposure, and maintaining high production throughput. Its core function is to translate system controller commands into precise motor movements—supporting up to 4 independent axes—while using encoder feedback to correct for positional errors in real time. In automation systems, the 810-013872-105 acts as a critical link between the main control unit and mechanical hardware, enabling synchronized motion (e.g., wafer transfer + chamber shutter opening) that minimizes process cycle time and maximizes fab efficiency.

Core Advantages and Technical Highlights

Multi-Axis Precision and Flexibility: The 810-013872-105 controls up to 4 independent axes and supports three motor types (stepper, servo, linear)—a versatility that eliminates the need for multiple single-axis controllers in complex tools. Its ±0.001mm positioning accuracy (with encoder feedback) is critical for 3nm/5nm processes, where even minor misalignment of the wafer stage can cause uneven etching or deposition. For example, when paired with a linear motor-driven stage, the 810-013872-105 ensures the wafer remains perfectly aligned with the process chamber’s gas injectors, reducing layer thickness variation by up to 40% compared to standard motion modules.

Real-Time Synchronization via EtherCAT: Equipped with EtherCAT protocol support, the 810-013872-105 enables ultra-low-latency (≤100μs) synchronization of motion across multiple modules. This is vital for multi-chamber tools (e.g., 4-chamber CVD systems) where wafer handling robots must transfer substrates between chambers with sub-second timing. Unlike modules relying on slower protocols (e.g., Modbus RTU), EtherCAT ensures that the 810-013872-105 coordinates with other motion modules (e.g., for secondary robots) without lag, preventing bottlenecks in high-volume production.

Semiconductor-Grade Durability and Safety: Built to comply with SEMI S2/S8/S14 standards, the 810-013872-105 features a ruggedized housing with vibration-dampening gaskets (to withstand tool vibration up to 10G peak, 10–500Hz) and conformal-coated circuit boards (to resist corrosion from low-level process gas leaks). Its safety features—including over-current protection, E-stop input, and position limit switches—prevent motor damage and wafer collisions. For example, if a servo motor draws excess current (indicating a jam), the 810-013872-105 shuts down power to the motor within 5ms, avoiding costly actuator or wafer repairs.

User-Friendly Configuration and Diagnostics: The 810-013872-105 simplifies setup via its USB-C port and LAM’s MotionSuite™ software, which offers a graphical interface for tuning motor parameters (e.g., acceleration, jerk) and configuring encoder feedback. It also includes built-in diagnostics that monitor motor current, encoder signal quality, and temperature in real time. Faults (e.g., encoder signal loss, over-temperature) are logged with time stamps and error codes, accessible via Ethernet or USB—enabling maintenance teams to quickly identify issues (e.g., a worn encoder cable) without disassembling the tool.

Typical Application Scenarios

The 810-013872-105 is indispensable in semiconductor fabs for motion-critical processes, with two high-impact use cases: wafer handling robot control and process stage positioning.

In wafer handling (e.g., LAM’s Centura® Etch systems), the 810-013872-105 regulates the movement of a 6-axis servo robot that transfers 300mm wafers between the load port, aligner, and process chamber. Its ±0.001mm accuracy ensures the robot’s end effector (wafer holder) does not scratch the wafer’s delicate surface, while EtherCAT synchronization allows the robot to coordinate with the chamber shutter—opening the shutter just as the wafer arrives, reducing transfer time by 15% compared to legacy modules. Fabs using the 810-013872-105 report a 25% reduction in wafer breakage, a key cost driver in high-volume production.

In process stage positioning (e.g., for 3D NAND etching), the 810-013872-105 controls a linear motor-driven stage that moves the wafer under the etch chamber’s plasma source. Its high-speed feedback loop (1kHz update rate) corrects for stage drift in real time, ensuring the wafer’s target area remains perfectly aligned with the plasma beam. This precision is critical for etching deep, narrow trenches (aspect ratios >100:1) in 3D NAND devices, where misalignment would cause trench tapering or bottom rounding. The 810-013872-105 also integrates with LAM’s data acquisition modules (e.g., 810-225420-002) to log stage position data, enabling post-process analysis of etch uniformity.

LAM 810-013872-105

Related Model Recommendations

LAM 810-013872-106: An upgraded variant of the 810-013872-105 with 6 axes (vs. 4) and higher motor current capacity (up to 12A peak for linear motors), designed for large-scale tools (e.g., 8-chamber etch systems with dual robots).

LAM 810-013872-104: A cost-optimized variant of the 810-013872-105 with 2 axes and reduced current capacity (up to 4A peak), ideal for R&D labs or small-scale tools (e.g., single-chamber ALD systems).

LAM 810-013873-105: A redundant motion control module that pairs with the 810-013872-105 for fault-tolerant systems (e.g., high-yield memory fabs), automatically taking over control if the primary module fails to prevent production halts.

LAM 810-013871-105: A legacy replacement for LAM’s pre-2017 motion modules (e.g., 810-013869-101), fully compatible with the 810-013872-105’s mounting, power, and protocol support.

LAM 810-013872-107: A high-temperature variant of the 810-013872-105 (operating range: -10°C to 60°C), designed for use near high-heat tools (e.g., MOCVD systems for compound semiconductors).

LAM 810-013874-105: An encoder interface accessory module that adds 4 additional encoder input ports to the 810-013872-105, ideal for tools requiring redundant feedback (e.g., critical wafer transfer robots).

LAM 810-013872-108: A wireless-enabled variant of the 810-013872-105 (Wi-Fi 6, Bluetooth 5.2), enabling remote configuration and diagnostics for tools in hard-to-access cleanroom areas.

LAM 810-013875-105: A safety-enhanced variant of the 810-013872-105 with SIL 2 certification, designed for tools with functional safety requirements (e.g., robots operating near operator workstations).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-013872-105, ensure the 19-inch rack or panel is clean (free of particulate matter) and the ambient temperature is within 5–45°C. Required tools include a torque wrench (3.0 N·m for rack mounting), multimeter (to verify 24V DC logic/48–72V DC motor power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect both logic and motor power before wiring; use shielded cables for encoder signals to minimize EMI (critical for maintaining ±0.001mm accuracy); and confirm the module’s ground connection (≥6AWG wire for motor power, ≥12AWG for logic) is secure to prevent ESD damage. For EtherCAT, use twisted-pair cables rated for industrial motion control to ensure low-latency sync.

Maintenance Suggestions: For daily maintenance, check the 810-013872-105’s front-panel LED indicators (green = normal, amber = warning, red = fault) and verify motor current/temperature via the module’s web interface. Every 6 months, inspect encoder cables for wear or damage (replace if signal noise exceeds 50mV) and update the module’s firmware via LAM’s MotionSuite™ software—this ensures access to enhanced motion tuning features and safety patches. Every 12 months, perform a positioning accuracy calibration using LAM’s MotionCal™ tool (traceable to NIST standards); adjust motor parameters if accuracy drifts beyond ±0.002mm. If a fault occurs (e.g., over-current), first isolate the module from power, check for motor jams or short circuits, and replace faulty components with LAM-approved parts—non-approved motors/encoders may cause compatibility issues or void the warranty.

Service and Guarantee Commitment

The 810-013872-105 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and motion control performance under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize production downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers end-to-end technical support for the 810-013872-105, including 24/7 access to motion control specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours for global fabs). The module also includes free access to LAM’s MotionSuite™ software (for configuration, tuning, and firmware updates) for 5 years post-purchase, ensuring compatibility with evolving motor technologies and process requirements.

To enhance reliability, LAM offers a Motion Control Care Program for the 810-013872-105, which includes scheduled on-site inspections, proactive encoder cable replacement, and annual NIST-traceable accuracy calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 810-013872-105’s quality and its dedication to supporting customers’ precision-driven semiconductor manufacturing operations.