Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 810-006490-006 |

| Manufacturer | LAM Research |

| Product category | Digital Control Interface Module (for Semiconductor Processing Equipment) |

| Input/Output (I/O) Channels | 16x digital inputs (24V DC, sinking/sourcing); 12x digital outputs (24V DC, 2A max per channel) |

| Analog I/O (Optional) | 4x analog inputs (0–10V DC, 12-bit resolution); 2x analog outputs (0–10V DC, 12-bit resolution) |

| Interface Type | Dual Ethernet (10/100/1000Base-T); 2x RS-485; 3x 24-pin terminal blocks (power/I/O); 1x USB-C (configuration) |

| Communication Protocol | EtherNet/IP, PROFINET, Modbus TCP/IP, LAM Proprietary ControlLink™ |

| Operating Temperature Range | 0°C to 50°C (non-condensing) |

| Relative Humidity Tolerance | 5% to 90% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 200mm × 280mm × 120mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (2U height); DIN rail mounting (35mm standard, with adapter) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Power Consumption | 24V DC, 1.5A typical; 2.0A maximum (when all outputs are active) |

| Response Time | Digital I/O: <1ms; Analog I/O: <5ms (settling time) |

| Shock/Vibration Resistance | 10–500Hz, 10G peak (vibration); 50G peak (shock, 11ms duration) |

LAM 810-006490-006

Product Introduction

The LAM 810-006490-006 is a high-performance digital control interface module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically designed to serve as a “communication hub” for LAM’s flagship processing platforms—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems—this module enables seamless data exchange and coordinated control between disparate subsystems (e.g., gas flow modules, high-voltage power supplies, and chamber pressure sensors) in complex wafer fabrication setups.

As a core component of LAM’s Control Interface Series, the LAM 810-006490-006 is optimized for advanced semiconductor process nodes (down to 3nm), where real-time synchronization of process parameters is critical to maintaining yield and device quality. Its primary function is to aggregate digital/analog signals from multiple subsystems, translate them into standardized protocol data, and transmit commands from the main system controller to individual components. In automation systems, the LAM 810-006490-006 eliminates “protocol silos” between subsystems, ensuring that every component operates in lockstep—whether adjusting gas flow rates, modulating plasma power, or triggering wafer transfer mechanisms.

Core Advantages and Technical Highlights

Multi-Protocol Flexibility: The LAM 810-006490-006 supports four industry-leading communication protocols (EtherNet/IP, PROFINET, Modbus TCP/IP, and LAM’s ControlLink™), a capability unmatched by many single-protocol interface modules. This flexibility allows it to integrate seamlessly with LAM’s native controllers and third-party automation systems (e.g., Siemens PCS 7, Rockwell Allen-Bradley Logix) without requiring custom adapters. For fabs with mixed-vendor equipment, this means reduced integration time and lower compatibility risks.

High-Speed I/O Response: With a digital I/O response time of <1ms and analog I/O settling time of <5ms, the LAM 810-006490-006 ensures near-instantaneous signal transmission—critical for time-sensitive processes like plasma etching, where delays of even 10ms can cause process drift. This speed is enabled by a dedicated 32-bit microprocessor and hardware-accelerated protocol handling, which prioritizes real-time control signals over non-critical data (e.g., logging).

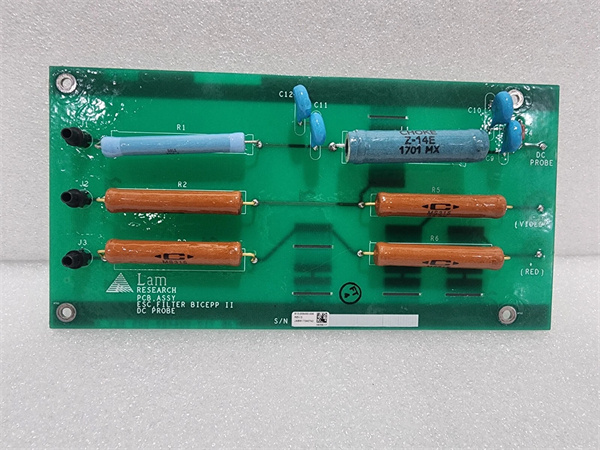

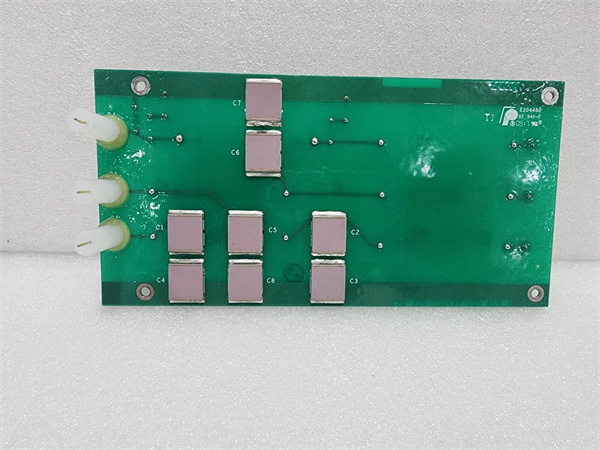

Semiconductor-Grade Ruggedness: Built to comply with SEMI S2/S8/S14 standards, the LAM 810-006490-006 features a reinforced housing and conformal-coated circuit boards that resist corrosion from low-level process gas leaks (e.g., fluorine, chlorine) and protect against electrostatic discharge (ESD) up to 15kV. Its shock/vibration resistance (50G peak shock, 10G vibration) also ensures reliable operation in high-volume fabs, where equipment vibration from adjacent tools is common—extending the module’s mean time between failures (MTBF) to over 200,000 hours.

Configurable I/O and Diagnostics: The LAM 810-006490-006 offers user-configurable digital I/O (sinking/sourcing) and optional analog channels, allowing fabs to tailor the module to specific process needs (e.g., adding analog inputs for pressure sensors in CVD systems). It also includes built-in diagnostic tools that monitor I/O channel health, power supply stability, and communication link status in real time. Faults are logged with time stamps and error codes, which can be accessed via Ethernet or USB-C—enabling maintenance teams to quickly isolate issues (e.g., a faulty output channel) without shutting down the entire system.

Typical Application Scenarios

The LAM 810-006490-006 is a foundational component in semiconductor fabs, with two high-impact use cases: integrated process control for multi-subsystem tools and legacy equipment modernization.

In integrated process control (e.g., LAM’s Centura® Etch systems), the LAM 810-006490-006 acts as the central interface between the main controller, gas flow modules (e.g., LAM 739-090783-001), high-voltage power supplies (e.g., LAM 810-800082-043), and chamber pressure sensors. During 3nm logic wafer etching, it synchronizes commands to adjust gas flow rates (via the gas module) and plasma power (via the HV supply) in real time, ensuring that etch profiles remain consistent across the wafer. Fabs rely on the LAM 810-006490-006’s multi-protocol support to avoid compatibility issues between these subsystems, reducing setup time for new process recipes by up to 30%.

In legacy equipment modernization, the LAM 810-006490-006 enables fabs to upgrade older LAM tools (e.g., pre-2015 Sym3® CVD systems) with modern I/O and communication capabilities. For example, a fab using a legacy Sym3® system can install the LAM 810-006490-006 to replace outdated RS-232 interfaces, allowing the tool to communicate with new digital sensors and integrate into a factory-wide Industry 4.0 network. This extends the life of legacy equipment by 5–7 years while maintaining compatibility with advanced process nodes, delivering significant cost savings compared to replacing the entire tool.

LAM 810-006490-006

Related Model Recommendations

LAM 810-006490-007: An upgraded variant of the LAM 810-006490-006 with expanded I/O (24x digital inputs, 16x digital outputs) and dual PROFINET ports, designed for high-complexity tools (e.g., 2nm process etchers with 8+ subsystems).

LAM 810-006490-005: A compact version of the LAM 810-006490-006 (1U rack height, no analog I/O), optimized for space-constrained tools (e.g., small-scale R&D etching systems).

LAM 810-006491-006: A redundant interface module that pairs with the LAM 810-006490-006 for fault-tolerant systems (e.g., high-yield memory fabs), automatically taking over if the primary module fails to prevent production downtime.

LAM 810-006489-006: A legacy replacement for LAM’s pre-2018 interface modules (e.g., 810-006478-001), fully compatible with the LAM 810-006490-006’s mounting, power, and protocol support.

LAM 810-006490-008: A safety-enhanced variant of the LAM 810-006490-006 with SIL 2 certification, designed for tools requiring functional safety (e.g., wafer transfer robots with emergency stop circuits).

LAM 810-006492-006: An I/O expansion module that adds 16x digital inputs/12x digital outputs to the LAM 810-006490-006, ideal for tools with growing subsystem counts (e.g., multi-chamber CVD systems).

LAM 810-006490-009: A wireless-enabled variant of the LAM 810-006490-006 (Wi-Fi 6, Bluetooth 5.2), enabling remote configuration and monitoring for tools in hard-to-access cleanroom areas.

LAM 810-006493-006: A diagnostic accessory module that monitors the LAM 810-006490-006’s I/O channels and communication links, sending predictive maintenance alerts via LAM’s FabGuard® software.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the LAM 810-006490-006, ensure the 19-inch rack or DIN rail is clean (free of particulate matter) and the ambient temperature is within 0–50°C. Required tools include a torque wrench (2.0 N·m for rack mounting, 0.8 N·m for DIN rail), multimeter (to verify 24V DC power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect power to the host tool before wiring; use color-coded wiring (per LAM’s guidelines) for I/O channels to avoid misconnections; and confirm the module’s ground connection (≥12AWG wire) is secure to prevent ESD damage. Avoid mounting near high-voltage components (e.g., HV power supplies) to minimize electromagnetic interference.

Maintenance Suggestions: For daily maintenance, check the LAM 810-006490-006’s front-panel LED indicators (green = normal, amber = warning, red = fault) and verify communication links via the Ethernet interface. Every 12 months, perform a firmware update (via USB-C or Ethernet) using LAM’s ControlSuite™ software to ensure compatibility with new protocols and subsystems. If a fault occurs (e.g., a failed output channel), use the module’s built-in diagnostic tool to isolate the issue—replace faulty terminal blocks with LAM-approved parts only, as non-approved components may compromise safety or signal integrity. Every 24 months, inspect the module’s conformal coating for signs of wear or corrosion; if damage is found, contact LAM’s service team for professional re-coating to maintain SEMI compliance.

Service and Guarantee Commitment

The LAM 810-006490-006 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and communication performance under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers end-to-end technical support for the LAM 810-006490-006, including 24/7 access to control interface specialists via phone/email, remote configuration assistance (via secure Ethernet), and on-site troubleshooting (available within 48 hours for global fabs). The module also includes free access to LAM’s ControlSuite™ software (for configuration, diagnostics, and firmware updates) for 5 years post-purchase, ensuring long-term compatibility with evolving process needs.

To enhance reliability, LAM offers a Customized Interface Care Program for the LAM 810-006490-006, which includes scheduled on-site inspections, proactive firmware updates, and I/O channel testing—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the LAM 810-006490-006’s quality and its dedication to supporting customers’ critical semiconductor manufacturing operations.