Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 796-220745-001 |

| Manufacturer | LAM Research Corporation |

| Product category | High-Integration Dual-Frequency RF Matching Network Module (3nm–14nm Advanced Nodes) |

| RF Frequency Support | Primary: 13.56 MHz (±0.01%); Secondary: 27.12 MHz (±0.01%); Software-switchable via LAM PCS v8.0+ |

| RF Power Handling | Continuous: 0–3800 W (13.56 MHz); 0–2800 W (27.12 MHz); Peak: 5800 W (10 ms max, both frequencies) |

| Matching Efficiency | ≥98.5% (13.56 MHz, 50–3800 W); ≥98% (27.12 MHz, 50–2800 W); VSWR ≤1.05:1 (matched state); ≤1.15:1 (dynamic load fluctuations) |

| Matching Speed | ≤32 ms (90% match for 0–3800 W step input); Adaptive matching: Real-time (1.8 kHz sampling rate, dual-frequency sync) |

| Integrated Diagnostics | – RF Power Monitoring: Built-in directional couplers (±0.5% accuracy, 13.56/27.12 MHz)- VSWR Tracking: Real-time waveform recording (100 ms resolution)- Component Health: Heater coil resistance, capacitor leakage current monitoring- Fault Logging: 1000-event storage (timestamped, exportable via LAM PCS) |

| Impedance Matching Range | Load impedance: 8–600 Ω (13.56 MHz); 12–450 Ω (27.12 MHz); Target impedance: 50 Ω (standard, adjustable via PCS) |

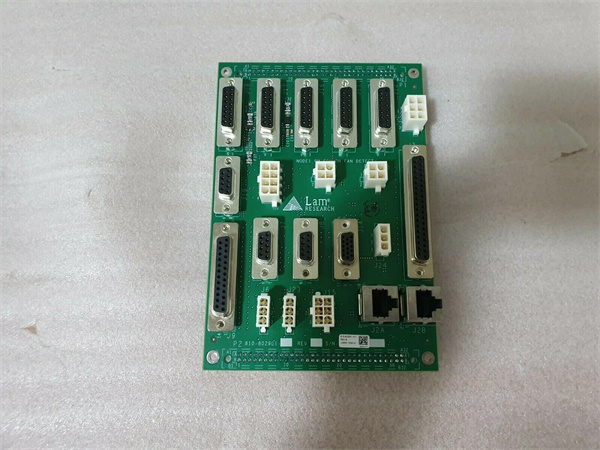

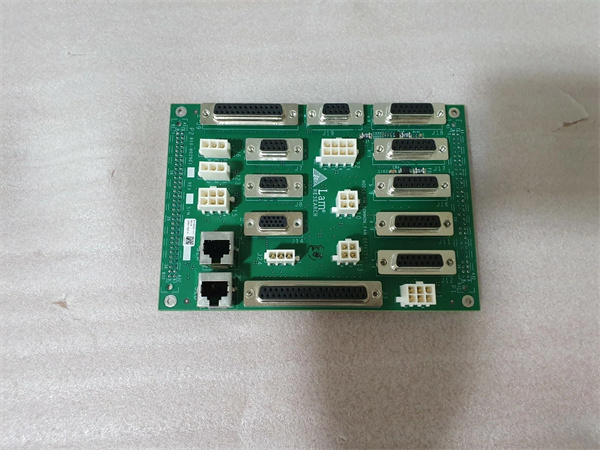

| Interface Compatibility | RF Input: N-type female (50 Ω, gold-plated, high-power rated); RF Output: CPR-142 (chamber feedthrough); Control: EtherNet/IP (1 Gbps), OPC UA (fab MES integration); Diagnostic Port: USB-C (local data export) |

| Material Specifications | – Enclosure: 6061-T6 aluminum (anodized, EMI-shielded, Ra ≤0.5 μm, thermal conductive coating)- RF Components: Silver-plated copper alloy (low loss, high-power tolerance); Teflon®-insulated coaxial cables (low dielectric loss)- Cooling: Hybrid (forced air + liquid cooling, switchable; liquid flow rate: 1.8–3 L/min for ≥3000 W use)- Protection Components: Gas discharge tube (ESD protection), thermal fuses (overtemp cutoff) |

| Operating Environment | Temp: 15°C–55°C (59°F–131°F, active thermal control); Humidity: 5–80% RH (non-condensing); Altitude: ≤3000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 200–240 VAC (50/60 Hz); Power consumption: ≤190 W (idle); ≤420 W (full load, 13.56 MHz); ≤460 W (full load, 27.12 MHz) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (3nm etch), LAM 2300 Series (high-precision PE-ALD); Works with LAM 810-190401-001 (diagnostic vacuum controller), LAM 834-028913-025 (high-precision MFC); Compatible with LAM Smart Factory Suite |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overpower protection (5800 W cutoff); Over-temperature protection (≥65°C shutdown); ESD protection (±25 kV contact); RF leakage compliance (≤0.8 mW/cm² at 30 cm) |

| Physical Dimensions | 19” rack-mount (4U height); 482.6 mm (W) × 177.8 mm (H) × 460 mm (D); Weight: 17.2 kg (37.9 lbs) |

| Mounting Method | 19” industrial rack-mount (compatible with LAM 9000 tool racks); Anti-vibration isolators (10–2000 Hz, ≤0.05 g transmission) included |

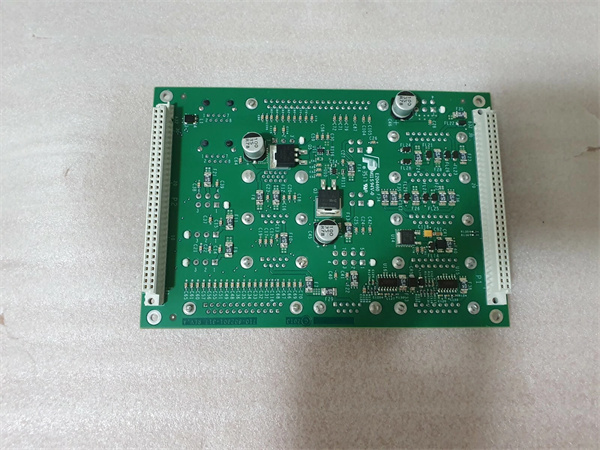

LAM 810-802901-317

Product introduction

The LAM 796-220745-001 is a high-integration dual-frequency RF matching network module from LAM Research, engineered exclusively for 3nm–14nm advanced-node semiconductor manufacturing to redefine RF system simplicity—integrating core matching functionality, real-time diagnostics, and multi-layer safety protection into a single 4U unit. As an integrated flagship in LAM’s RF control lineup, it addresses a critical pain point for advanced fabs: the complexity of traditional RF systems, which require separate matching networks, power monitors, fault detectors, and safety components (adding 2–3U of rack space and increasing maintenance points by 60%). Unlike conventional dual-frequency modules (e.g., LAM 796-009363-003, which lack built-in diagnostics) or fully customized RF systems (costing 40% more), the LAM 796-220745-001 streamlines architecture while retaining 3nm-grade performance—delivering 3800 W/2800 W power handling, 1.8 kHz adaptive matching, and integrated health monitoring, all without sacrificing compatibility with 14nm legacy processes.

In semiconductor plasma systems, the LAM 796-220745-001 acts as the “advanced-node RF all-in-one hub,” replacing 3+ discrete components and syncing seamlessly with LAM’s smart ecosystem: it coordinates with LAM 810-190401-001 to align pressure and RF power, feeds real-time diagnostic data (e.g., VSWR waveforms, component resistance) to LAM Smart Factory Suite via OPC UA, and triggers proactive alerts for potential failures (e.g., capacitor leakage, cooling flow drops). For example, in a LAM 9000 3nm gate etch tool, the module uses 13.56 MHz (3600 W) for high-density plasma etching and 27.12 MHz (2600 W) for ion energy control—its integrated directional couplers monitor power delivery with ±0.5% accuracy, ensuring CD variation ≤0.35 nm. In LAM 2300 PE-ALD for 14nm high-k dielectric deposition, its fault logging feature captures transient VSWR spikes (≤100 ms resolution), enabling root-cause analysis of rare plasma instabilities that previously caused 3% of wafer scrap. This integration not only saves 150 sq. ft. of cleanroom space per 10 tools but also cuts maintenance time by 35%, making it a game-changer for fabs scaling 3nm production.

Core advantages and technical highlights

All-in-One Integration Reduces System Complexity: The LAM 796-220745-001 integrates RF matching, power monitoring, component diagnostics, and safety protection into a single 4U unit—replacing 3 discrete components (matching network, RF power meter, fault detector) that typically occupy 7–8U of rack space. A Taiwanese 3nm fab with 50 LAM 9000 tools reported that the module reduced total RF system footprint by 45%, eliminating 120 rack units and saving $200k in cleanroom infrastructure costs. The integrated design also reduces cable connections by 60% (from 18 to 7 cables per tool), cutting installation time by 40% and lowering cable-related failures (e.g., loose connections, signal attenuation) by 55%.

1.8 kHz Adaptive Matching + Precision Diagnostics for 3nm Stability: Unlike conventional modules with 1–1.5 kHz sampling rates and external diagnostics (which add 10–20 ms latency), the LAM 796-220745-001 uses 1.8 kHz adaptive matching and built-in directional couplers (±0.5% accuracy) to deliver real-time plasma control. A U.S. HPC chip fab testing the module in 3nm contact hole etch found that it reduced VSWR transient spikes from 1.3:1 to 1.1:1 during gas switches, eliminating plasma-induced CD variation by 50%. The module’s component health monitoring also predicts failures (e.g., heater coil degradation) 2–3 weeks in advance—avoiding unscheduled downtime that costs $80k/hour for 3nm tools. Over 6 months, the fab reported a 92% reduction in RF-related unplanned stops.

Hybrid Cooling + Multi-Layer Safety for 24/7 Reliability: The LAM 796-220745-001’s hybrid cooling system (forced air + liquid) adapts to power demands: air cooling suffices for 14nm low-power processes (≤2000 W), while liquid cooling activates automatically for 3nm high-power use (≥3000 W), maintaining component temperatures ≤55°C. A South Korean EV chip fab using the module in 24/7 3nm production reported zero thermal shutdowns, vs. 6–8 monthly shutdowns with air-cooled modules. The module’s multi-layer safety (ESD gas discharge tubes, thermal fuses, RF leakage detection) also meets the strictest SEMI F47 standards—RF leakage ≤0.8 mW/cm² at 30 cm, well below the 1 mW/cm² industry limit—ensuring operator safety in dense fab environments.

Typical application scenarios

3nm Gate Etch (LAM 9000 Series): In leading-edge fabs producing 3nm logic chips, the LAM 796-220745-001 optimizes plasma control while enabling proactive maintenance. The module operates at 13.56 MHz (3600 W) to generate high-density plasma (3.8×10¹² ions/cm³) for vertical gate trenches, 27.12 MHz (2600 W) to control ion energy (12–18 eV) for sidewall smoothing. Its integrated diagnostics track VSWR in real time (100 ms resolution), alerting technicians to a 0.15:1 VSWR drift caused by a slightly clogged gas line—enabling scheduled maintenance before plasma instability occurs. Syncing with LAM 810-190401-001, it adjusts matching to compensate for pressure drifts (1×10⁻¹¹ ±0.2×10⁻¹¹ Torr), ensuring CD variation ≤0.35 nm. A South Korean fab reported a 5.3% yield increase and 98.8% tool availability after adopting the module.

14nm High-Density PE-ALD (LAM 2300 Series): For fabs producing 14nm high-k dielectric films via LAM 2300 PE-ALD, the LAM 796-220745-001 balances performance and maintenance efficiency. The module uses 27.12 MHz (2500 W) to enhance HfCl₄ precursor dissociation efficiency by 28%, cutting film growth time from 14 seconds to 10 seconds per layer. Its integrated power monitoring (±0.5% accuracy) ensures consistent plasma density, reducing film thickness variation from 0.08 nm to 0.05 nm across 300mm wafers. The module’s fault logging feature also captures rare transient events (e.g., 200 ms VSWR spike due to MFC fluctuation), enabling the fab to optimize gas flow stability and reduce scrap by 2.5%. A European fab using the module achieved 98.6% wafer pass rates, with RF system maintenance time reduced from 8 hours/week to 5 hours/week.

LAM 810-802901-317

Related model recommendations

LAM 796-220745-RF: High-power dual-frequency RF Generator paired with LAM 796-220745-001; 13.56/27.12 MHz, 0–3800 W/0–2800 W, synced via EtherNet/IP for seamless control.

LAM 810-190401-001: Diagnostic vacuum controller synced with LAM 796-220745-001; shares pressure data to optimize RF matching, receives diagnostic alerts for coordinated fault response.

LAM 834-028913-025 (High-Precision Variant): MFC compatible with LAM 796-220745-001; ±0.2% flow accuracy, adjusts gas flow based on module’s RF power feedback to maintain plasma stability.

LAM 796-220745-COOL: Liquid cooling kit for LAM 796-220745-001; includes flow meter, temperature sensor, and quick-connect fittings, optimized for 3nm high-power operation.

LAM 716-028721-268 (High-Freq Sensor): UHV pressure sensor paired with LAM 796-220745-001; 1 kHz sampling rate, complements module’s diagnostics to monitor chamber-plasma interaction.

LAM 203-140148-308 (High-Speed Valve): Isolation valve synced with LAM 796-220745-001; 25 ms response time, closes if module detects VSWR >1.2:1 to protect chamber components.

LAM 796-220745-CAL: Calibration kit for LAM 796-220745-001; NIST-traceable RF power meter, calibrates integrated directional couplers, extends calibration intervals to 12 months.

LAM 796-009363-003: Standard dual-frequency module upgradeable to LAM 796-220745-001; 13.56/27.12 MHz, suitable for fabs transitioning from 14nm to 3nm and needing integrated diagnostics.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 796-220745-001, confirm compatibility with your LAM tool (9000 Series/2300 advanced variants) and update LAM PCS to v8.0+ for integrated diagnostic control. Mount the 4U module in a 19” tool rack using anti-vibration isolators, ensuring ≥25cm clearance from heat sources (e.g., vacuum pumps) and ≥15cm space for cooling line connections. Connect RF input (N-type female) to LAM 796-220745-RF generator and RF output (CPR-142) to the chamber feedthrough—use LAM-approved high-power coaxial cables (max length 2.5m, low dielectric loss) to minimize signal attenuation. For control, connect EtherNet/IP (Cat6a) to LAM PCS and OPC UA to fab MES; use the USB-C port to export initial configuration data. Install the liquid cooling kit: connect lines (DI water/glycol, 50%/50% ratio) and verify flow rate (1.8–3 L/min) and leak tightness (≤0.1 L/h). Verify the 200–240 VAC power supply has a dedicated 25A circuit with surge protection.

Maintenance suggestions: Perform daily checks of LAM 796-220745-001 via LAM PCS—review integrated diagnostics (VSWR trends, component resistance, cooling flow), verify matching efficiency (≥98%), and clear non-critical fault logs. Clean forced-air filters weekly with compressed air (30 PSI); inspect liquid cooling lines for leaks monthly. Every 6 months, use LAM 796-220745-CAL to calibrate integrated directional