Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

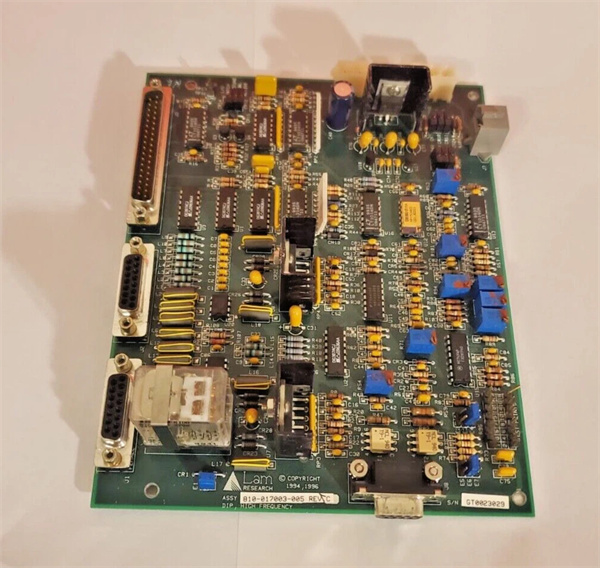

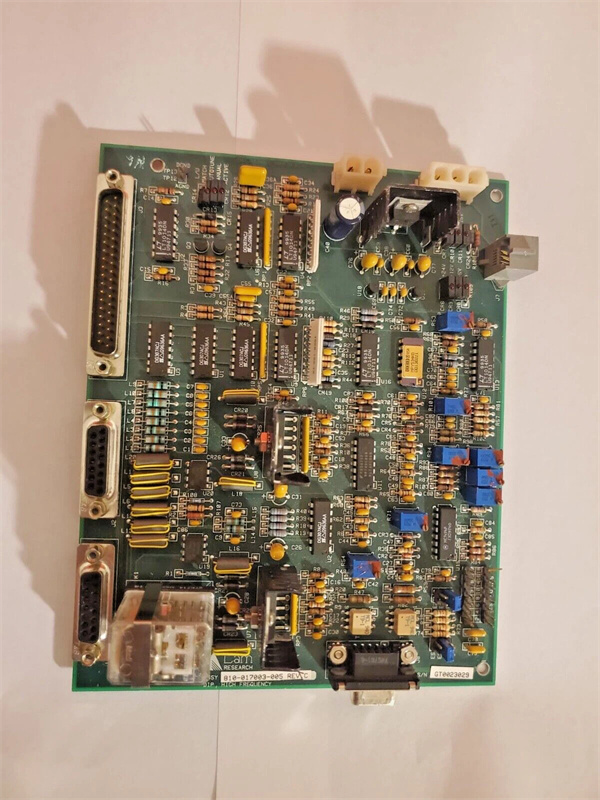

| Product model | 739-090783-001 |

| Manufacturer | LAM Research |

| Product category | Precision Gas Flow Control Module (for Semiconductor Wafer Processing Systems) |

| Flow Control Range | 0–500 sccm (standard cubic centimeters per minute); compatible with inert/reactive gases |

| Flow Measurement Accuracy | ±0.5% of full scale (at 25°C, 1 atm); ±1.0% of reading (10–100% full scale) |

| Gas Compatibility | Inert gases (Ar, N₂), reactive gases (O₂, CF₄, Cl₂), and process vapors (TEOS) |

| Interface Type | Ethernet (10/100Base-T) + RS-485; 2x 16-pin terminal blocks (power/signals); 1x gas inlet/outlet (1/4-inch VCR fitting) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, and LAM’s proprietary ProcessLink™ protocol |

| Operating Temperature Range | 15°C to 40°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 75% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 180mm × 250mm × 100mm (excluding fittings/connectors) |

| Installation Method | DIN rail mounting (35mm standard) or panel mounting (with optional brackets); requires inline gas filter (≥0.2μm) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Pressure Rating | Inlet pressure: 0.5–10 bar (gauge); Outlet pressure: 0.1–5 bar (gauge) |

LAM 810-006490-005

Product Introduction

The LAM 739-090783-001 is a high-performance precision gas flow control module developed by LAM Research, a global leader in semiconductor manufacturing equipment. Specifically engineered for integration into LAM’s flagship wafer processing systems—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition platforms—this module serves as the critical interface between gas supply systems and process chambers, ensuring ultra-consistent gas delivery during wafer fabrication.

As a core model in LAM’s Gas Management Series, the LAM 739-090783-001 is optimized for advanced semiconductor process nodes (down to 3nm), where even minor variations in gas flow can disrupt plasma stability or thin-film uniformity. Its primary function is to measure, regulate, and monitor gas flow rates (0–500 sccm) for both inert and reactive gases, translating system controller commands into precise flow adjustments. In automation systems, the LAM 739-090783-001 acts as a closed-loop control hub, providing real-time flow data to the main controller and enabling proactive adjustments to prevent process drift—directly boosting fab yield and reducing wafer scrappage.

Core Advantages and Technical Highlights

Dual-Range Accuracy: The LAM 739-090783-001 delivers exceptional accuracy across two performance ranges: ±0.5% of full scale for broad flow coverage and ±1.0% of reading for precise control at lower flow rates (10–100% full scale). This dual-range capability is enabled by a proprietary thermal mass flow sensor with 16-bit resolution, critical for 3nm nodes where processes like atomic layer deposition (ALD) require nanoscale precision in gas delivery.

Broad Gas Compatibility: Unlike standard flow modules that are limited to inert gases, the LAM 739-090783-001 is engineered to handle both inert and highly reactive process gases—including corrosive species like Cl₂ and CF₄, and vapor-phase precursors like TEOS. Its internal wetted parts are coated with a corrosion-resistant nickel alloy (Hastelloy® C-276), while a built-in moisture trap prevents gas-phase condensation, extending the module’s service life and eliminating contamination risks.

Seamless System Integration: The LAM 739-090783-001 supports three industry-standard and proprietary communication protocols, enabling plug-and-play integration with LAM’s native controllers and third-party automation platforms (e.g., Rockwell Allen-Bradley, Siemens PCS 7). LAM’s ProcessLink™ protocol further enhances functionality by enabling direct data sharing with LAM’s FabGuard® process monitoring software, allowing fabs to track flow trends and predict maintenance needs.

Proactive Fault Mitigation: The module includes multi-layer protection features to safeguard both the module and downstream process. If flow rates exceed user-defined thresholds (e.g., 110% full scale), the LAM 739-090783-001 immediately triggers a shutoff valve, logs the event with time stamps and gas type, and sends alerts via Ethernet/RS-485. It also includes a built-in pressure sensor to detect inlet pressure drops, preventing flow starvation that could damage process chambers.

Typical Application Scenarios

The LAM 739-090783-001 is indispensable in semiconductor fabs for gas-centric processes, with two high-impact use cases: plasma etching for logic/memory devices and atomic layer deposition (ALD) for thin-film formation.

In plasma etching (e.g., for 3nm logic gate patterning), the LAM 739-090783-001 regulates the flow of reactive gases (e.g., CF₄, O₂) into the plasma chamber. Its ±0.5% accuracy ensures consistent plasma density, which is critical for achieving vertical etch profiles and minimizing line-edge roughness—two factors that directly impact device performance and yield. Fabs using LAM’s Centura® Etch systems rely on the LAM 739-090783-001 to maintain flow stability across 24/7 high-volume production, even when switching between different gas mixtures for multi-step etch processes.

In ALD (used for ultra-thin dielectric or metal layers in 3D NAND), the LAM 739-090783-001 delivers precise pulses of precursor vapors (e.g., TEOS for SiO₂) and purge gases (e.g., N₂). Its ±1.0% reading accuracy ensures uniform layer thickness (down to 0.1nm per cycle), while its compatibility with vapor-phase gases eliminates the risk of precursor condensation in the flow path. The module’s compliance with SEMI S14 (electromagnetic compatibility) also ensures it does not interfere with sensitive wafer metrology tools in Class 1 cleanrooms, maintaining process integrity.

LAM 810-006490-005

Related Model Recommendations

LAM 739-090783-002: An upgraded variant of the LAM 739-090783-001 with extended flow range (0–1000 sccm) and higher inlet pressure tolerance (0.5–15 bar), designed for high-throughput 2nm process systems.

LAM 739-090782-001: A lower-flow companion to the LAM 739-090783-001 (0–100 sccm), optimized for R&D labs or low-volume specialty processes (e.g., MEMS fabrication) requiring nanoscale flow precision.

LAM 739-090784-001: A redundant flow control module that pairs with the LAM 739-090783-001 for fault-tolerant systems (e.g., high-yield memory fabs), automatically switching to backup flow control if the primary module fails.

LAM 739-090783-000: A legacy replacement for LAM’s pre-2017 gas flow modules (e.g., 739-090779-001), fully compatible with the LAM 739-090783-001’s mounting, protocols, and gas compatibility.

LAM 739-090790-001: A gas filter accessory module designed to work with the LAM 739-090783-001, featuring a 0.2μm PTFE filter to remove particulate contaminants and extend the module’s sensor life.

LAM 739-090783-003: A heated variant of the LAM 739-090783-001 (temperature range: 25–80°C), preventing vapor condensation for high-vapor-pressure precursors (e.g., TiCl₄) in ALD processes.

LAM 739-090785-001: A multi-gas manifold module that integrates up to 4x LAM 739-090783-001 units, enabling simultaneous control of multiple gas streams in complex etch/CVD processes.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the LAM 739-090783-001, ensure the mounting surface is clean (free of particulate matter) and the ambient temperature is within 15–40°C. Required tools include a torque wrench (for DIN rail/panel mounting, 0.8 N·m torque), gas leak detector (He-based), and ESD-safe gloves/wristbands. Safety precautions: Purge the gas line with inert gas (N₂) for 5 minutes before connecting to the module to remove air/moisture; use only 1/4-inch VCR fittings (compatible with the module’s inlet/outlet) to prevent leaks; and confirm the inline filter (≥0.2μm) is installed upstream to protect the flow sensor. Avoid mounting near heat sources (e.g., chamber heaters) to prevent temperature-induced accuracy drift.

Maintenance Suggestions: For daily maintenance, check the LAM 739-090783-001’s front-panel LED indicators (green = normal, amber = low flow, red = fault) and verify gas line pressure via the module’s Ethernet interface. Every 6 months, perform a flow calibration using LAM’s CalibrateFlow™ tool (traceable to NIST standards) to maintain accuracy. If a fault occurs (e.g., leak detected), isolate the module from the gas supply, purge the line with N₂, and inspect VCR fittings for damage—replace worn gaskets with LAM-approved PTFE seals. Every 12 months, replace the inline filter and clean the sensor housing with compressed inert gas (Ar, <30 psi) to remove residual deposits; never use solvents, as they can damage the corrosion-resistant coating.

Service and Guarantee Commitment

The LAM 739-090783-001 comes with a 30-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and flow control accuracy under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “swap-and-calibrate” service—delivering a pre-calibrated replacement unit within 48 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair, shipping, or calibration.

LAM offers comprehensive technical support for the LAM 739-090783-001, including 24/7 access to gas flow specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 72 hours for global fabs). The module also includes free firmware updates for 4 years post-purchase, ensuring compatibility with future LAM system upgrades and emerging process gases (e.g., new ALD precursors).

To enhance long-term reliability, LAM offers a Gas Module Care Program for the LAM 739-090783-001, which includes scheduled on-site inspections, proactive filter/sensor replacement, and annual NIST-traceable calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the LAM 739-090783-001’s quality and its dedication to supporting customers’ critical semiconductor manufacturing operations.