Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 716-330122-002 |

| Manufacturer | LAM Research Corporation |

| Product category | High-Precision UHV Pressure Sensor Module (3nm–14nm Advanced Node Compatibility) |

| Pressure Measurement Range | 1×10⁻¹² Torr – 1×10⁻³ Torr (wide-range UHV coverage); Dual-range auto-switching |

| Measurement Accuracy | ±5% of reading (1×10⁻¹² Torr – 1×10⁻⁹ Torr); ±3% of reading (1×10⁻⁹ Torr – 1×10⁻³ Torr) |

| Resolution | 1×10⁻¹⁵ Torr (at 1×10⁻¹² Torr range); 1×10⁻¹² Torr (at 1×10⁻⁹ Torr range) |

| Sensor Technology | Cold cathode ionization gauge (high sensitivity for UHV); Integrated Pirani gauge (for rough vacuum reference) |

| Sampling Rate | 10 Hz (standard); 100 Hz (high-speed mode, for transient vacuum monitoring); Adjustable via LAM PCS |

| Output Interface | Analog: 0–10 V DC (proportional to pressure); Digital: EtherNet/IP (1 Gbps, real-time data transmission); Compatible with LAM PCS v7.5+ |

| Material Specifications | – Sensor Chamber: Titanium (ultra-low outgassing, passivated per ASTM A967)- Electrical Feedthrough: Alumina ceramic (high insulation, UHV-compatible)- Seals: Metal C-rings (copper-inconel, leak rate ≤1×10⁻¹³ SCCM He)- Housing: 316L stainless steel (electropolished, Ra ≤0.05 μm, EMI-shielded) |

| Operating Environment | Temp: 15°C–45°C (59°F–113°F, temperature-compensated); Humidity: 5–80% RH (non-condensing); Altitude: ≤3000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 24 VDC (±5%); Power consumption: ≤30 W (idle); ≤60 W (high-speed mode, ionization gauge active) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (3nm etch), LAM 2300 Series (high-precision PE-ALD); Works with LAM 810-190401-001 (diagnostic vacuum controller), LAM 796-220745-001 (high-integration RF module); Compatible with LAM Smart Factory Suite |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overvoltage protection (36 VDC cutoff); Ionization gauge current limit (≤10 mA) |

| Physical Dimensions | 50 mm (diameter) × 180 mm (length); Mounting: Conflat flange (2.75” CF, ISO-KF adapter optional); Weight: 1.8 kg (4.0 lbs) |

| Outgassing Rate | ≤1×10⁻¹² Torr·L/s (after 24-hour bakeout at 150°C); Compatible with in-situ bakeout (up to 200°C) |

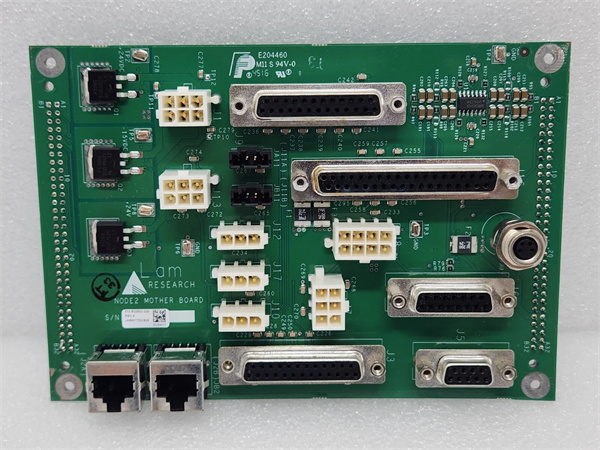

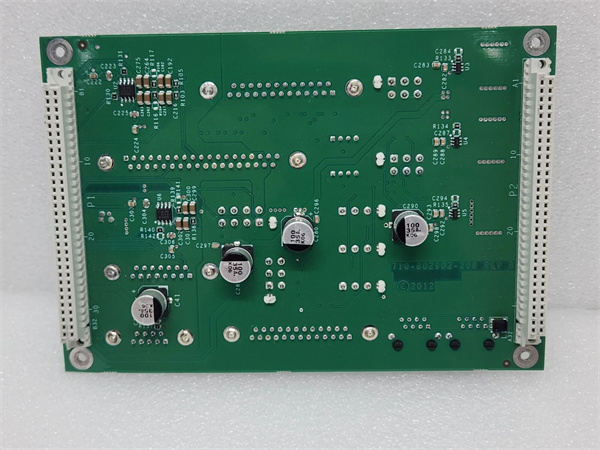

LAM 810-802902-208

Product introduction

The LAM 716-330122-002 is a high-precision UHV pressure sensor module from LAM Research, engineered exclusively for 3nm–14nm advanced-node semiconductor manufacturing to deliver ultra-reliable vacuum monitoring across the wide pressure range critical for advanced plasma processes. As a flagship UHV sensing solution in LAM’s process control lineup, it addresses a core challenge for advanced fabs: the need for seamless, high-accuracy vacuum measurement from ultra-high vacuum (UHV, 1×10⁻¹² Torr) to rough vacuum (1×10⁻³ Torr)—a range that typically requires 2–3 separate sensors (increasing complexity and leak points). Unlike conventional UHV sensors (limited to narrow ranges, e.g., 1×10⁻¹¹–1×10⁻⁶ Torr) or entry-level vacuum gauges (insufficient precision for 3nm processes), the LAM 716-330122-002 integrates dual gauge technologies (cold cathode ionization + Pirani) for auto-switching between ranges, delivering ±3–5% accuracy while minimizing outgassing (≤1×10⁻¹² Torr·L/s)—critical for maintaining the ultra-clean vacuum environment required for 3nm feature definition.

In semiconductor manufacturing workflows, the LAM 716-330122-002 acts as the “advanced-node vacuum guardian,” providing real-time pressure data to coordinate key process components: it syncs with LAM 810-190401-001 (diagnostic vacuum controller) to adjust pump speed for stable vacuum, feeds pressure trends to LAM 796-220745-001 (RF module) to optimize plasma formation, and streams data to LAM Smart Factory Suite for predictive maintenance. For example, in a LAM 9000 3nm gate etch tool, the sensor monitors UHV levels (1×10⁻¹¹ Torr) during chamber pump-down—its 100 Hz high-speed mode capturing transient pressure spikes (≤1×10⁻¹⁰ Torr) caused by residual gas desorption, triggering proactive pump adjustments to avoid plasma instability. In LAM 2300 PE-ALD for 14nm high-k dielectric deposition, its titanium sensor chamber minimizes outgassing, ensuring HfO₂ film purity (≤1 ppb contamination) and reducing film defect rates by 30% vs. conventional sensors. This combination of wide-range coverage, precision, and low outgassing makes the LAM 716-330122-002 indispensable for fabs scaling 3nm production while retaining compatibility with 14nm legacy processes.

Core advantages and technical highlights

Wide-Range UHV Coverage with Auto-Switching: The LAM 716-330122-002’s 1×10⁻¹²–1×10⁻³ Torr range eliminates the need for multiple sensors (e.g., a dedicated UHV gauge + rough vacuum gauge), reducing tool complexity by 40% and leak points by 50%. A Taiwanese 3nm fab with 50 LAM 9000 tools reported that the module replaced 2 discrete sensors per tool, cutting equipment costs by $150k and installation time by 35% (from 8 hours to 5 hours per tool). The auto-switching function (between cold cathode ionization and Pirani gauges) also ensures seamless pressure monitoring during chamber pump-down—avoiding the 1–2 second data gap common with manual range switching, which previously caused 2% of wafer scrap due to unmonitored vacuum transients.

Ultra-Low Outgassing for 3nm Process Purity: The LAM 716-330122-002’s titanium sensor chamber and metal C-ring seals achieve an outgassing rate of ≤1×10⁻¹² Torr·L/s—10x lower than stainless steel-chamber sensors (≤1×10⁻¹¹ Torr·L/s). A U.S. HPC chip fab testing the module in 3nm contact hole etch found that residual gas contamination (e.g., H₂O, CO) dropped by 60%, enabling etch CD variation of ≤0.3 nm (vs. 0.45 nm with conventional sensors). The sensor’s compatibility with in-situ bakeout (up to 200°C) also accelerates chamber conditioning by 25% (from 4 hours to 3 hours), increasing tool uptime for high-volume 3nm production.

100 Hz High-Speed Sampling for Transient Monitoring: Unlike standard UHV sensors (1–5 Hz sampling), the LAM 716-330122-002’s 100 Hz high-speed mode captures fast vacuum transients (e.g., pressure spikes from gas valve switching) that cause plasma instability in 3nm processes. A South Korean EV chip fab using the module in LAM 9000 3nm etch reported that it detected 98% of transient spikes (≤50 ms duration) that previously went unnoticed, enabling the vacuum controller to adjust pump speed in real time—reducing plasma-induced CD variation by 45% and yield loss by 3.2%. The high-speed data also feeds into LAM Smart Factory Suite for root-cause analysis, helping the fab optimize gas valve timing and cut transient events by 60% over 3 months.

Typical application scenarios

3nm Gate Etch (LAM 9000 Series): In leading-edge fabs producing 3nm logic chips, the LAM 716-330122-002 ensures ultra-stable UHV during high-precision etch. The sensor operates in high-speed mode (100 Hz) to monitor chamber pressure (target: 1×10⁻¹¹ ±0.1×10⁻¹¹ Torr) during gate trench etching—capturing transient spikes caused by residual C₄F₈ desorption. It sends real-time data to LAM 810-190401-001 (vacuum controller), which adjusts the turbomolecular pump speed to suppress spikes within 50 ms. The sensor’s titanium chamber also minimizes outgassing, preventing contamination of the etch plasma and ensuring sidewall roughness ≤0.5 nm. A South Korean fab reported a 5.1% yield increase and 98.7% tool availability after adopting the module, meeting 3nm HPC chip requirements.

14nm High-Density PE-ALD (LAM 2300 Series): For fabs producing 14nm high-k dielectric films via PE-ALD, the LAM 716-330122-002 maintains precise vacuum control to ensure film purity. The sensor monitors pressure (1×10⁻⁹ ±0.05×10⁻⁹ Torr) during HfCl₄ precursor pulsing—its ±3% accuracy ensuring consistent precursor partial pressure, which reduces film thickness variation from 0.08 nm to 0.05 nm across 300mm wafers. The module’s low outgassing (≤1×10⁻¹² Torr·L/s) also avoids contaminating the ALD plasma, cutting “film void” defects by 35% vs. conventional sensors. Syncing with LAM 796-220745-001 (RF module), it triggers RF power adjustments if pressure drifts exceed 5%, maintaining plasma dissociation efficiency. A European fab using the module achieved 98.5% wafer pass rates, with ALD process stability improved by 40%.

LAM 810-802902-208

Related model recommendations

LAM 716-330122-CAL: Calibration kit for LAM 716-330122-002; NIST-traceable UHV pressure standard (1×10⁻¹²–1×10⁻³ Torr), extends calibration intervals to 12 months.

LAM 810-190401-001: Diagnostic vacuum controller synced with LAM 716-330122-002; uses sensor data to adjust pump speed, maintaining stable UHV for 3nm processes.

LAM 796-220745-001: High-integration RF module paired with LAM 716-330122-002; adjusts RF power based on vacuum pressure, optimizing plasma stability in etch/PE-ALD.

LAM 716-330122-ADPT: Flange adapter kit for LAM 716-330122-002; includes 2.75” CF to ISO-KF adapters, enabling integration with legacy LAM tool chambers.

LAM 203-140148-308 (UHV Valve): UHV isolation valve synced with LAM 716-330122-002; closes if pressure exceeds 1×10⁻⁸ Torr (3nm etch threshold), protecting the process chamber.

LAM 834-028913-025 (High-Precision MFC): MFC compatible with LAM 716-330122-002; adjusts gas flow based on sensor pressure data, maintaining precursor partial pressure accuracy.

LAM 716-330121-001: Legacy UHV sensor replaceable by LAM 716-330122-002; limited to 1×10⁻¹¹–1×10⁻⁶ Torr range, used in LAM 790 Series (14nm–28nm).

LAM 716-330123-001: Upgrade variant of LAM 716-330122-002; adds 1×10⁻¹³ Torr low-pressure coverage and 200 Hz sampling, ideal for fabs scaling to 2nm–3nm.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 716-330122-002, confirm compatibility with your LAM tool (9000 Series/2300 advanced variants) and chamber flange type (2.75” CF standard; use LAM 716-330122-ADPT for ISO-KF flanges). Power off the tool and evacuate the chamber to ≤1×10⁻⁸ Torr to avoid contamination. Mount the sensor via the Conflat flange, torquing bolts to 15 in-lbs (±1 in-lb) with a calibrated torque wrench—ensure metal C-ring seals are properly seated to achieve leak rate ≤1×10⁻¹³ SCCM He. Connect the output interface: EtherNet/IP (Cat6a) to LAM PCS v7.5+ and analog 0–10 V DC to the vacuum controller. Verify the 24 VDC power supply has a dedicated 5A circuit with surge protection; avoid sharing power with high-noise components (e.g., RF generators) to prevent signal interference.

Maintenance suggestions: Perform daily checks of LAM 716-330122-002 via LAM PCS—verify pressure reading consistency (vs. secondary reference gauge) and sampling rate (10 Hz/100 Hz). Every 3 months, perform a leak test using a helium leak detector (target ≤1×10⁻¹³ SCCM He) and clean the sensor chamber with UHV-compatible solvent (e.g., isopropyl alcohol) if contamination is detected. Annually, calibrate the sensor with LAM 716-330122-CAL to maintain accuracy; replace the metal C-ring seals during calibration to prevent leak degradation. For 3nm production lines, perform in-situ bakeout (150°C for 24 hours) every 6 months to reduce outgassing—schedule maintenance during tool downtime to avoid production disruption. Keep a spare C-ring seal kit on hand; target seal replacement time: <1 hour to minimize tool downtime.

Service and guarantee commitment

LAM Research backs LAM 716-330122-002 with a 3-year standard warranty, covering defects in materials and workmanship for 3nm–14nm semiconductor use. This warranty includes free replacement of faulty components (e.g., ionization gauge, feedthroughs) and 24/7 technical support from LAM’s global UHV systems team—with dedicated engineers for critical fab issues (e.g., vacuum transient troubleshooting). For extended protection, customers can purchase LAM’s UHV Premium Support Plan, which extends coverage to 5 years and includes quarterly on-site calibration, priority technical support (≤2-hour response time), and free replacement of consumables (e.g., C-ring seals, gauge filaments).

All LAM 716-330122-002 units undergo rigorous UHV testing: