Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

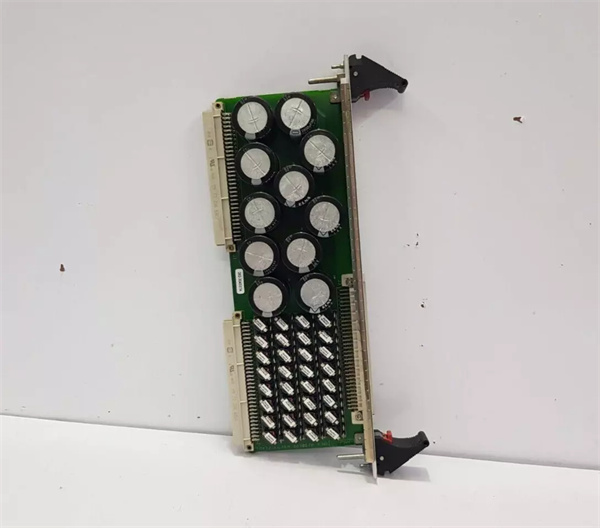

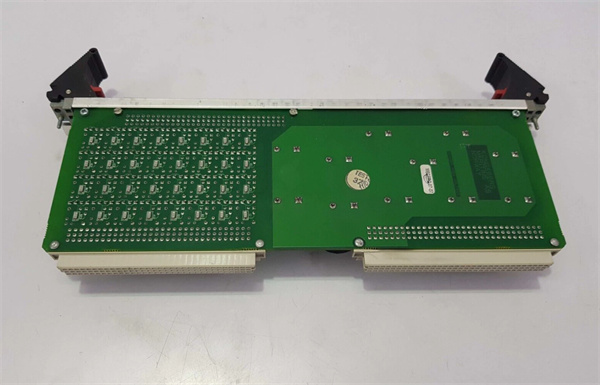

| Product Model | KONGSBERG TRX32 303088 |

| Manufacturer | KONGSBERG |

| Product Category | Industrial Communication Module |

| Communication Protocols | Modbus, Profibus, Ethernet |

| Interface Types | Ethernet, RS-232, RS-485 |

| Operating Temperature Range | -40°C to +70°C |

| Dimensions | Compact PCB Module |

| Weight | Not specified |

| Certifications | CE, ISO 9001 |

TRX32 303088

Product Introduction

The KONGSBERG TRX32 303088 is a high-performance communication module designed for industrial automation and data acquisition. It supports multiple communication protocols, enabling seamless connection and data exchange between devices. The module features a compact design suitable for space-limited environments and offers high reliability and anti-interference capabilities.

Core Advantages and Technical Highlights

Multi-Protocol Support

The KONGSBERG TRX32 303088 supports a variety of industrial communication protocols, such as Modbus, Profibus, and Ethernet, facilitating integration with different systems.

Compact and Durable Design

This module is designed for industrial environments, with a compact form factor and wide operating temperature range of -40°C to +70°C. It is built to withstand harsh conditions and ensure reliable operation.

Real-Time Data Processing

The module supports real-time monitoring of digital input signals, allowing for timely detection of abnormalities and improved system stability.

TRX32 303088

Typical Application Scenarios

The KONGSBERG TRX32 303088 is widely used in:

-

Industrial Automation: For communication expansion in PLC and DCS systems.

-

Data Acquisition: For collecting data from field instruments and sensors.

-

Marine Systems: For filtering noise in navigation signals and improving data accuracy in marine surveying equipment.

Related Model Recommendations

-

KONGSBERG RMP400: A remote I/O module that can be paired with the KONGSBERG TRX32 303088 for comprehensive control and monitoring.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation

Ensure the environment meets the specified temperature and humidity requirements. Use appropriate tools and safety equipment to secure the module in place. Connect the input and output cables according to the manufacturer’s guidelines.

Maintenance Suggestions

Regularly inspect the module for signs of wear or damage. Keep the module clean and free from dust to prevent overheating and ensure efficient operation.