Description

Product Overview

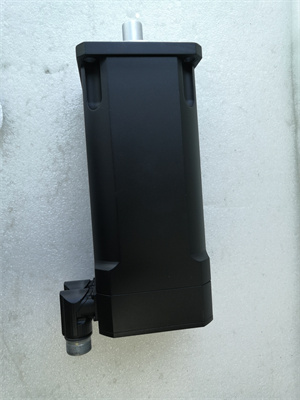

The KOLLMORGEN 6SM57M-3.000 is a high-performance frameless torque motor engineered for precision direct-drive applications demanding exceptional power density and smooth motion. As part of Kollmorgen’s 6SM series, this motor eliminates traditional mechanical transmission elements, integrating directly into machinery to deliver zero-backlash rotation with minimal inertia. The 6SM57M-3.000 generates 3,000 oz-in (21.2 Nm) of peak torque in a compact 57mm stack length, leveraging advanced magnetic circuit design for consistent torque output up to 3,000 rpm. Its slotless stator architecture achieves near-zero cogging torque (±0.1% ripple), enabling ultra-smooth velocity control as low as 0.001 rpm – critical for optical alignment, semiconductor metrology, and aerospace positioning systems. With Class H insulation (180°C) and optimized thermal paths, the KOLLMORGEN 6SM57M-3.000 sustains high torque density in confined spaces while maintaining micron-level repeatability.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 6SM57M-3.000 |

| Manufacturer | KOLLMORGEN |

| Product Type | Frameless Torque Motor |

| Peak Torque | 21.2 Nm (3,000 oz-in) |

| Continuous Torque | 7.1 Nm (1,000 oz-in) |

| Torque Constant | 0.65 Nm/A |

| Back EMF | 25 V/krpm |

| Max Speed | 3,000 rpm |

| Thermal Resistance | 0.6 °C/W |

| Insulation Class | H (180°C continuous) |

| Winding Configuration | 3-phase wye |

| Resistance (Line-to-Line) | 0.4 Ω |

| Inductance | 1.8 mH |

| Rotor Inertia | 0.0032 kg·m² |

| Air Gap | 0.8 mm |

| Mounting Standard | ISO 9409-1 |

| Weight | 2.1 kg (rotor) + 3.4 kg (stator) |

KOLLMORGEN 6SM57M-3.000

Main Features and Advantages

Ultra-Low Cogging Performance: Slotless stator design eliminates magnetic detent, achieving <±0.1% torque ripple for buttery-smooth rotation – essential for microscopy stages and laser processing.

Optimized Thermal Management: Copper-filled cooling channels and Class H insulation enable continuous torque at 100°C ambient. Integrated thermistors provide real-time thermal protection.

Precision Engineering: Ground mounting surfaces maintain ±5µm parallelism tolerance, ensuring consistent air gap control when embedded in rotary stages or gimbals.

High Dynamic Response: Low rotor inertia (0.0032 kg·m²) allows acceleration to 3,000 rpm in <50ms, ideal for pick-and-place automation and indexing tables.

Custom Integration Ready: Optional modifications include vacuum-compatible materials, redundant windings, or customized flange patterns for aerospace/medical OEMs.

KOLLMORGEN 6SM57M-3.000

Application Field

The KOLLMORGEN 6SM57M-3.000 excels in precision direct-drive scenarios:

Semiconductor Metrology: Rotates wafer inspection stages with <0.1 arc-second jitter

Photonics Manufacturing: Positions fiber alignment fixtures for laser diode coupling

Aerospace Test Rigs: Drives flight simulator motion platforms with silent operation

Medical Imaging: Rotates CT/MRI gantries without electromagnetic interference

Additive Manufacturing: Indexes powder bed fusion platforms with micron-level accuracy

Defense Systems: Embedded in radar antenna positioners for military vehicles

Related Products

AKD-T0606: Servo drive optimized for frameless motor control

6SM37M-6000: Higher-torque variant (42.4 Nm peak)

TBM-S35: Safety brake module for vertical axes

RBE-01: Absolute encoder reset tool

KTC-1: Thermally conductive compound for stator bonding

AKM2G-41E: Housed alternative with similar torque profile

AKD-C00006: Compact drive for distributed installations

Installation and Maintenance

Pre-installation preparation: Machine mounting interfaces to Ra 0.8µm surface finish. Apply Kollmorgen KTC-1 thermal interface compound between stator and housing. Verify air gap with feeler gauges (±0.05mm tolerance).

Maintenance recommendations: Monitor winding temperature via drive monthly. Clean rotor/stator surfaces annually with non-abrasive solvents. Check rotor runout biannually (<10µm TIR). Relubricate customer-supplied bearings every 10,000 hours.

Product Guarantee

KOLLMORGEN provides a 24-month warranty against manufacturing defects. Includes lifetime technical support and 10-year spare parts availability. All 6SM57M-3.000 units undergo 72-hour dynamic burn-in testing with torque ripple validation. Critical failure support includes 48-hour expedited replacement for production emergencies.