Description

Product Overview

The KOLLMORGEN 6SM37M-6000 is a high-torque frameless torque motor engineered for direct-drive applications requiring maximum power density and precision motion control. Designed without bearings or housing, this motor integrates directly into machinery to eliminate backlash and mechanical compliance, delivering exceptional dynamic performance. The 6SM37M-6000 generates 6000 oz-in (42.4 Nm) of peak torque in a compact 37mm stack length, achieving industry-leading torque-to-volume ratios. Its slotless winding technology eliminates cogging torque (<±0.2% ripple) for buttery-smooth rotation down to 0.01 rpm – critical for optical alignment and semiconductor positioning stages. When embedded in rotary tables or gimbals, the KOLLMORGEN 6SM37M-6000 enables micron-level repeatability with Class H insulation (180°C) for sustained operation in high-temperature environments. The motor’s frameless architecture reduces system inertia by 50% compared to conventional servos, dramatically improving acceleration in robotics and aerospace applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 6SM37M-6000 |

| Manufacturer | KOLLMORGEN |

| Product Type | Frameless Torque Motor |

| Peak Torque | 42.4 Nm (6000 oz-in) |

| Continuous Torque | 14.1 Nm (2000 oz-in) |

| Torque Constant | 1.3 Nm/A |

| Back EMF | 50 V/krpm |

| Max Speed | 3000 rpm |

| Thermal Resistance | 0.8 °C/W |

| Insulation Class | H (180°C) |

| Winding Configuration | 3-phase, star |

| Resistance (Line-to-Line) | 0.8 Ω |

| Inductance | 2.5 mH |

| Rotor Inertia | 0.005 kg·m² |

| Air Gap | 0.5 mm |

| Mounting Interface | DIN 42955 standard |

| Weight | 3.2 kg (stator + rotor) |

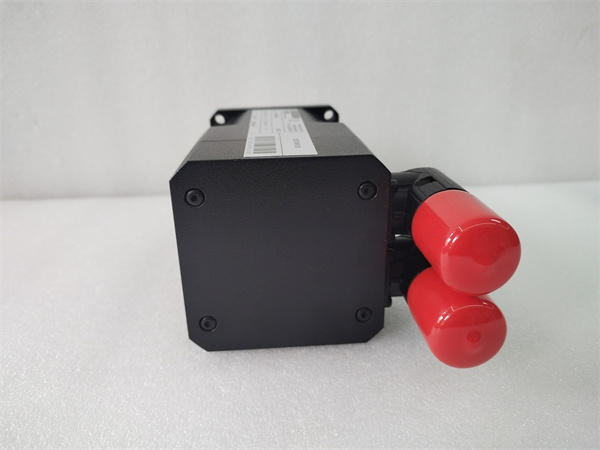

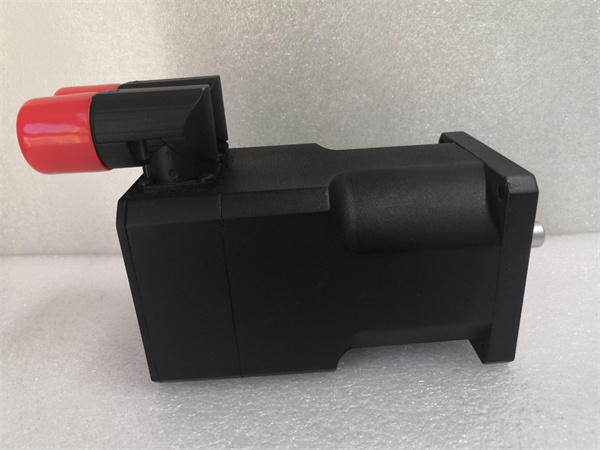

Kollmorgen 6SM37M-6000.

Main Features and Advantages

Ultra-High Power Density: The 6SM37M-6000 delivers 42.4 Nm peak torque in a 37mm stack height – 35% more compact than competitive designs. Neodymium magnets and optimized magnetic circuits achieve zero torque derating up to 3000 rpm.

Zero-Cogging Precision: Slotless stator eliminates detent torque for frictionless motion at ultra-low speeds (<0.1 rpm). Ideal for telescope positioning or laser micro-machining where smooth rotation is critical.

Thermal Robustness: Class H insulation withstands 180°C continuous winding temperatures. Integrated thermal pads transfer heat directly to machine structure, enabling 150% continuous torque at 100°C ambient.

Precision Machining: Ground mounting surfaces maintain 0.005mm parallelism tolerance. Hard-anodized rotor surfaces prevent corrosion in medical or marine environments.

Custom Integration: Optional water-cooling jackets and custom winding variants available. Dual-element thermistors provide redundant temperature monitoring for safety-critical systems.

Kollmorgen 6SM37M-6000.

Application Field

The KOLLMORGEN 6SM37M-6000 transforms direct-drive applications:

Semiconductor Manufacturing: Direct-drives wafer steppers and wire bonders with <100nm positioning repeatability

Aerospace Test Rigs: Powers helicopter rotor dynamometers requiring vibration-free torque up to 3000 rpm

Medical Robotics: Drives surgical robot joints with silent operation and zero magnetic interference

Optical Systems: Rotates telescope mounts and spectrometers with <0.1 arc-second smoothness

Defense Systems: Embedded in radar gimbals and turret drives for military vehicles

Additive Manufacturing: Precisely indexes build platforms in metal 3D printers

Related Products

AKM2G-41E: Housed servo motor alternative with 41mm frame

TBM-240-30: Electromagnetic brake module for vertical axes

AKD-T0606: Servo drive optimized for frameless motors

RBE-01: Absolute encoder reset tool

CKK-M12-17P: IP67-rated motor cable kit

6SM60M-8000: Higher-torque frameless variant (60 Nm peak)

AKD-P00306: Compact servo drive for space-constrained installations

Installation and Maintenance

Pre-installation preparation: Machine mounting surfaces to 0.005mm flatness tolerance. Apply thermally conductive compound (Kollmorgen KTC-1 recommended) between stator and housing. Verify air gap with go/no-go gauges before rotor installation.

Maintenance recommendations: Monitor winding temperature via drive interface monthly. Clean cooling surfaces annually with non-conductive cleaner. Check rotor-stator alignment biannually with dial indicator (<0.02mm runout tolerance). Relubricate customer-supplied bearings per OEM schedule.

Product Guarantee

KOLLMORGEN provides a 24-month warranty against manufacturing defects. Includes lifetime technical support and 10-year spare parts availability. All 6SM37M-6000 motors undergo 72-hour dynamic testing with torque ripple validation. Global service network guarantees 48-hour emergency replacement for production-critical applications.