Description

Product Overview

The KOLLMORGEN 63025-01D is a high-performance servo drive amplifier module designed for precision motion control systems in demanding industrial automation applications. As part of Kollmorgen’s advanced AKD series, this compact drive delivers sophisticated motor control algorithms in a ruggedized package optimized for machine builders requiring space efficiency without compromising capability. The 63025-01D supports power ratings up to 25A continuous current and operates on 480V AC three-phase input, making it ideal for driving high-torque servo motors in packaging, robotics, and CNC equipment. Its FPGA-based architecture executes Kollmorgen’s proprietary tuning algorithms with 62.5µs loop updates, enabling nanometer-level positioning accuracy and adaptive vibration suppression. With integrated safety functions (STO, SS1) and dual-port EtherCAT connectivity, the KOLLMORGEN 63025-01D provides a future-proof solution for Industry 4.0-ready machinery requiring deterministic performance and seamless integration with PLC systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 63025-01D |

| Manufacturer | KOLLMORGEN |

| Product Type | Digital Servo Drive |

| Rated Output Current | 25 A RMS |

| Peak Current | 75 A (3x overload for 2 sec) |

| Input Voltage | 3-phase 380-480V AC ±10% |

| Control Loop Update | 62.5 µs (position/velocity), 125 µs (current) |

| Feedback Interfaces | EnDat 2.2, Hiperface DSL®, BiSS-C, Resolver |

| Communication Protocols | EtherCAT, CANopen, SERCOS III |

| Safety Functions | STO (Cat.3 PL e), SS1, SS2, SOS |

| Control Modes | Torque, Velocity, Position, Electronic Gearing |

| Programming | IEC 61131-3 PLCopen Motion Control |

| Regenerative Braking | Built-in with external resistor support |

| Protection Rating | IP20 (chassis mount) |

| Operating Temperature | 0°C to 55°C (ambient) |

| Dimensions | 165 x 45 x 225 mm (WxHxD) |

| Weight | 1.8 kg |

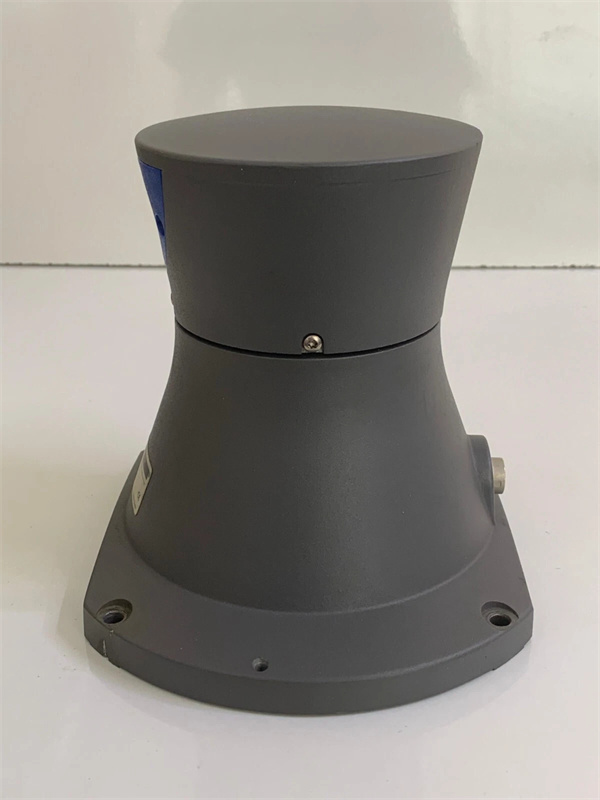

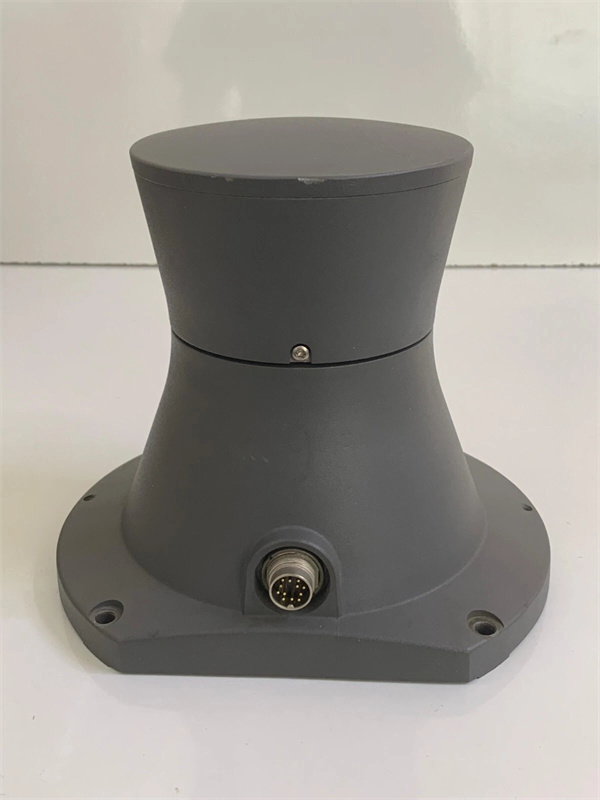

Kollmorgen 63025-01D

Main Features and Advantages

Advanced Motion Control: The 63025-01D implements Kollmorgen’s patented AKD DriveGuru™ technology with 25 auto-tuning algorithms, automatically optimizing servo response for changing loads. Adaptive notch filtering suppresses mechanical resonances up to 2.5 kHz.

Real-Time Performance: Dual-core processor and FPGA architecture execute motion profiles with 62.5µs cycle times. Distributed clock synchronization via EtherCAT achieves <1µs jitter for multi-axis coordination.

Cyber-Physical Integration: Integrated web server provides real-time oscilloscope visualization and remote diagnostics. OPC UA support enables seamless MES/SCADA connectivity for predictive maintenance.

Safety Integration: SIL 3/PLe-certified safety functions (STO, SS1) are hardware-implemented without external relays. Safe Motion Monitor continuously validates position/speed limits.

Robust Design: Conformal-coated PCB withstands 95% humidity. Reinforced DC bus capacitors rated for 100,000 hours at 55°C ambient. Vibration-resistant to 5g (10-500Hz) per IEC 60068-2-6.

Application Field

The KOLLMORGEN 63025-01D excels in high-precision automation:

Robotics: Controls articulated arms in automotive assembly with synchronized 6-axis interpolation

Packaging Machinery: Drives rotary fillers and capping stations at 600+ units/minute

Machine Tools: Powers spindle and feed axes in CNC machining centers with nanometer positioning

Printing Presses: Maintains web tension control with <0.05% speed regulation

Semiconductor: Positions wafer handlers with micron-level repeatability in cleanroom environments

Related Products

AKM2G | 41H: High-torque servo motor pairing

CKK | 17P: IP67-rated motor cable kit

PDB | 480: Dynamic brake resistor module

AKD-P00306: Entry-level 3A drive variant

TBM-U | 30: Electromagnetic brake module

AKD-C | 10A: Compact drive for distributed installation

RBE | 01: Absolute encoder reset tool

Installation and Maintenance

Pre-installation preparation: Verify grounding resistance <0.1Ω. Use copper conductors (min 6mm²) with 35mm DIN rail mounting. Maintain 50mm clearance for ventilation. Configure safety circuits before energizing.

Maintenance recommendations: Monitor DC bus ripple voltage via WorkBench software quarterly. Clean heat sink fins annually with dry compressed air. Replace cooling fans after 40,000 hours. Perform full parameter backup before firmware updates.

Product Guarantee

KOLLMORGEN provides a 36-month warranty covering manufacturing defects. Includes lifetime firmware updates and 10-year spare parts availability. All 63025-01D drives undergo 72-hour burn-in testing with thermal cycling and full-load validation. Global technical support offers 24/7 critical failure response with 4-hour escalation for production emergencies.