Description

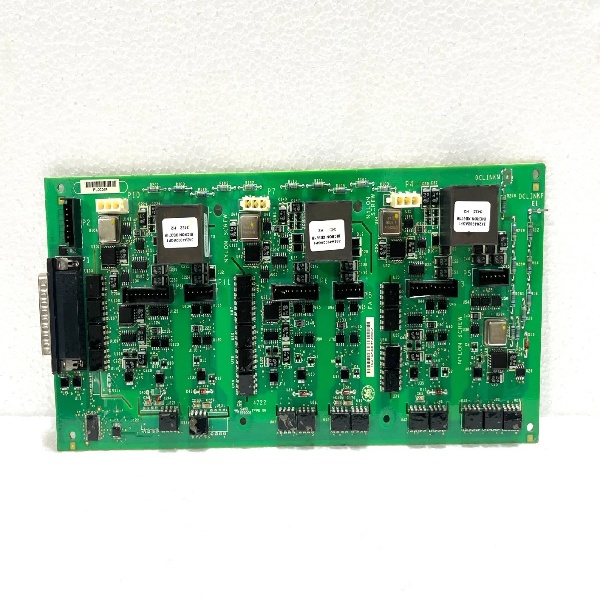

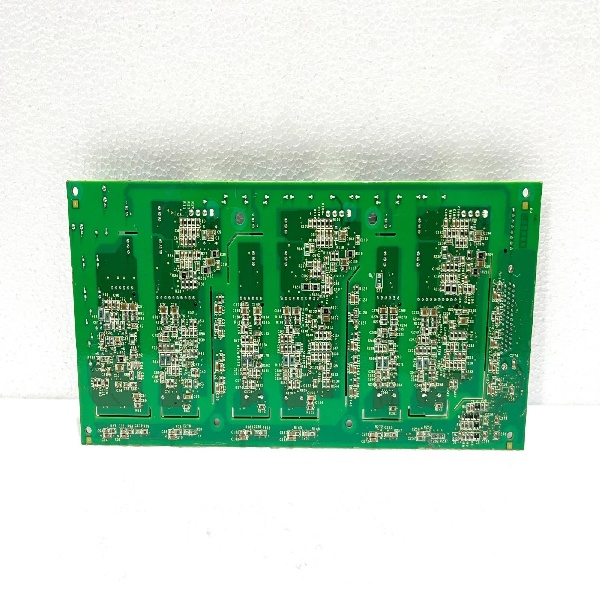

GE IS210BAPAH1A Mark VIe Analog Input Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210BAPAH1A** Manufacturer | GE General Electric Product Category | Industrial Analog Input Module Series | Mark VIe (Turbine Control System) Input Channels | 8 Differential Channels Input Types | 4-20mA DC, 0-10V DC (Configurable per Channel) Input Resistance | 250Ω (for 4-20mA), 100kΩ (for 0-10V) Accuracy | ±0.1% of Full Scale (at 25°C) Resolution | 16-bit Sampling Rate | 100 Samples/Second per Channel Power Supply | 24V DC (from Mark VIe Power Module) Operating Temperature | 0°C to 60°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 140mm × 100mm × 30mm Certifications | UL 508, CE, CSA, IEC 61010-1

Product Introduction

The **GE IS210BAPAH1A** is a high-precision analog input module engineered for GE’s Mark VIe turbine control system, specializing in the reliable collection and conversion of analog sensor signals from critical turbine components. As a key data acquisition component in GE’s industrial portfolio, the **GE IS210BAPAH1A** transforms continuous physical signals—such as turbine bearing temperature, steam pressure, and fuel flow—into digital data for processing by Mark VIe control modules (like the **IS210MACCH1A**). Its 8-channel design, dual-input compatibility, and high accuracy make it indispensable for onshore power plants, cogeneration facilities, and industrial turbine applications where precise process monitoring is critical.

What distinguishes the **GE IS210BAPAH1A** is its seamless integration with the Mark VIe ecosystem and focus on industrial-grade signal integrity. Leveraging GE’s expertise in turbine control and sensor data processing, the **GE IS210BAPAH1A** minimizes noise interference and ensures stable signal conversion even in the high-electromagnetic environment near turbine generators. By delivering accurate, real-time data to the control system, it enables precise turbine regulation, predictive maintenance, and fault detection—directly enhancing operational efficiency and reducing unplanned downtime for power generation facilities.

IS210AEBIH1A

Core Advantages and Technical Highlights

Multi-Input Flexibility: Each of the **IS210BAPAH1A**’s 8 differential channels can be independently configured for 4-20mA DC (current loop) or 0-10V DC (voltage) inputs, adapting to a wide range of turbine sensors—from pressure transmitters (4-20mA) to temperature transducers (0-10V). This eliminates the need for separate signal converters, simplifying system design and reducing component count.

High Accuracy and Resolution: With ±0.1% full-scale accuracy and 16-bit resolution, the **IS210BAPAH1A** captures subtle variations in sensor signals—such as minor fluctuations in turbine oil pressure or exhaust temperature. This precision ensures the **IS210MACCH1A** control module receives reliable data for fine-tuning turbine operations, optimizing fuel efficiency and extending component lifespan.

Noise Immunity and Signal Integrity: The **IS210BAPAH1A** features differential input design and built-in EMI/RFI filtering, rejecting electromagnetic interference from turbine generators and power cables. This ensures stable signal conversion even in harsh industrial environments, preventing false data triggers that could lead to unnecessary turbine shutdowns or performance issues.

Efficient Data Acquisition: With a 100 samples/second per channel sampling rate, the **IS210BAPAH1A** captures real-time signal changes during dynamic turbine events—such as start-up, load adjustments, or transient faults. It communicates seamlessly with the Mark VIe backplane, transmitting processed digital data to the control module without latency, ensuring timely system responses.

Typical Application Scenarios

In onshore gas turbine power plants, the **IS210BAPAH1A** serves as the primary analog data acquisition module for the Mark VIe system. It connects to 8 critical sensors, including turbine inlet temperature transducers (4-20mA), fuel flow meters (4-20mA), and bearing vibration sensors (0-10V). The module converts these signals to digital data, transmitting it to the **IS210MACCH1A** control module to regulate fuel supply and monitor component health—preventing overheating and mechanical failures.

For industrial cogeneration facilities, the **IS210BAPAH1A** collects analog data from steam turbine systems, including steam pressure transmitters (4-20mA), condenser level sensors (0-10V), and thermal energy output monitors (4-20mA). This data enables the Mark VIe system to balance electrical power generation with thermal energy supply for manufacturing processes, ensuring optimal efficiency and consistent heat delivery to production lines.

In mid-sized hydroelectric power plants, the **IS210BAPAH1A** acquires analog signals from turbine governor systems, such as water flow meters (4-20mA), penstock pressure sensors (4-20mA), and generator cooling water temperature transducers (0-10V). The module’s high accuracy ensures the **IS210MACCH1A** control module receives precise data to adjust wicket gates and runner blades, optimizing power output based on water flow and preventing equipment damage from pressure spikes.

Related Model Recommendations

**IS210BAPAH2A**: 16-channel variant of **IS210BAPAH1A**, ideal for large Mark VIe systems requiring extended analog sensor monitoring, such as multi-turbine power plants.

**IS210MACCH1A**: Mark VIe control module that processes digital data from **IS210BAPAH1A**, forming the core data-acquisition-control combination for turbine systems.

**IS210BPPBH2B**: Mark VIe power supply module that provides stable 24V DC power to **IS210BAPAH1A**, ensuring consistent signal acquisition and data transmission.

**IS210BDAIH1A**: Mark VIe digital input module that complements **IS210BAPAH1A**, collecting discrete signals (e.g., limit switches) to provide comprehensive turbine status data.

**IS210BDAOI1A**: Mark VIe digital output/analog input combo module, working with **IS210BAPAH1A** to expand both analog data collection and discrete control capabilities.

**IC754VSF12CTD-JH**: GE VersaMax HMI that displays real-time analog data from **IS210BAPAH1A**, enabling operators to monitor turbine sensor values and identify anomalies.

**IS210MCPMG1A**: Power monitoring module that pairs with the Mark VIe power supply to ensure stable voltage for **IS210BAPAH1A**, maintaining data acquisition accuracy.

IS210AEBIH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210BAPAH1A**, power off the Mark VIe chassis and verify compatibility with the system backplane. Ensure the module is powered by a stable 24V DC supply (from **IS210BPPBH2B** or equivalent). Use shielded twisted-pair cables for sensor connections to minimize noise, and terminate unused channels with 100Ω resistors if needed. Label each channel wire according to the sensor schematic to avoid cross-connection, and set input type (4-20mA/0-10V) via Mark VIe configuration software before power-up.

Maintenance suggestions: Conduct monthly visual inspections of **IS210BAPAH1A**, checking for loose sensor connections, damaged cables, and dust accumulation—clean the module with a dry anti-static brush. Calibrate the module quarterly using a precision signal generator to ensure ±0.1% accuracy, verifying each channel’s response to 4mA, 12mA, and 20mA (or 0V, 5V, 10V) inputs. Test EMI filtering annually by simulating industrial noise; replace the module if signal drift exceeds 0.5% of full scale or channels fail to respond. Ensure the control cabinet maintains 0°C to 60°C and adequate ventilation.

Service and Guarantee Commitment

GE General Electric provides a 36-month quality guarantee for the **IS210BAPAH1A**, covering manufacturing defects, signal drift beyond specifications, and channel failures under normal operating conditions. Our global technical support team offers 24/7 assistance, including remote calibration guidance, configuration support, and troubleshooting for signal integrity issues. Customers receive access to GE’s Mark VIe Configuration Studio and calibration documentation for the **IS210BAPAH1A** throughout the guarantee period. Priority service clients benefit from 48-hour replacement of defective modules to minimize turbine data acquisition downtime.