Description

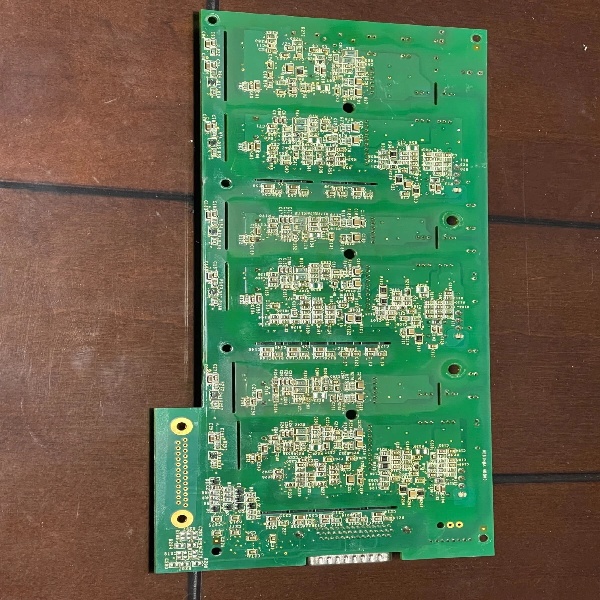

GE IS210AEBIH1ADC Mark VIe Digital Input Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210AEBIH1ADC** Manufacturer | GE General Electric Product Category | Industrial Digital Input Module Series | Mark VIe (Turbine Control System) Input Channels | 16 Isolated Differential Channels Input Type | Dry Contact (NO/NC), 24V DC Wet Contact Input Voltage Range | 16-32V DC (Wet Contact) Response Time | ≤0.5ms Isolation Voltage | 1000V AC (Channel to Channel, Channel to Ground) Input Current | 4mA @ 24V DC (Wet Contact) Diagnostic Functions | Channel Open/Short Detection, Power Supply Monitoring, Self-Diagnosis Power Supply | 24V DC (from Mark VIe Power Module) Operating Temperature | -10°C to 65°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 4X (Chassis Mount Compatible) Physical Dimensions | 140mm × 100mm × 30mm Certifications | UL 508, CE, CSA, IEC 61131-2, ATEX Zone 2

Product Introduction

The **GE IS210AEBIH1ADC** is a high-performance digital input module with enhanced anti-interference and diagnostic capabilities, tailor-made for GE’s Mark VIe turbine control system. It specializes in reliable collection and transmission of discrete signals from critical turbine components in harsh industrial environments. As a premium discrete data acquisition unit in GE’s portfolio, the module captures on/off status signals—including turbine valve position switches, emergency stop contacts, bearing temperature limit switches, and pump running status—and converts them into standardized digital data for Mark VIe control modules (such as the **IS210MACCH1A**). Its 16-channel isolated design, extended environmental adaptability, and comprehensive diagnostic functions make it the first choice for offshore power plants, petrochemical turbine systems, and high-interference industrial sites where ultra-reliable discrete monitoring is essential.

What sets the **GE IS210AEBIH1ADC** apart is its reinforced environmental resilience, enhanced isolation performance, and intelligent diagnostic system—advantages that address the pain points of complex industrial scenarios. Leveraging GE’s advanced turbine control and signal processing technologies, the module features 1000V AC high-voltage isolation and multi-layer EMI filtering, effectively resisting electromagnetic interference from large turbine generators and high-voltage cables. Its built-in channel fault diagnosis and self-check functions enable proactive identification of wiring issues and module malfunctions, while the extended operating temperature range (-10°C to 65°C) adapts to extreme on-site conditions. By delivering ultra-fast and accurate discrete data, it ensures the control system’s rapid fault response, meets strict industrial safety standards, and significantly improves the operational reliability of complex turbine control systems.

IS210AEBIH1ADC

Core Advantages and Technical Highlights

High-Voltage Isolation and Strong Anti-Interference: The **IS210AEBIH1ADC** is equipped with 16 fully isolated differential channels, each with 1000V AC channel-to-channel and channel-to-ground isolation—doubling the isolation level of standard models. It integrates multi-layer EMI/RFI filtering circuits to suppress conducted and radiated interference, ensuring accurate data collection even when monitoring high-noise discrete signals (such as turbine fuel valve switches and generator breaker statuses) in offshore or petrochemical environments with intense electromagnetic fields.

Flexible Dual-Input and Extended Adaptability: The module supports both dry contact (NO/NC) and 24V DC wet contact inputs, compatible with a wider range of discrete sensors and switches. Its expanded input voltage range (16-32V DC) tolerates larger power supply fluctuations, while the -10°C to 65°C operating temperature range adapts to low-temperature offshore platforms and high-temperature turbine rooms. This flexibility eliminates the need for additional signal regulators and envir

onmental control equipment, simplifying integration in complex scenarios.

Ultra-Fast Response and Intelligent Diagnostics: With a response time of ≤0.5ms, the module captures rapid discrete signal changes (such as emergency stop button presses or valve fault triggers) faster than standard models, ensuring the **IS210MACCH1A** control module receives real-time status updates for immediate protective actions. It features comprehensive diagnostic functions, including channel open/short detection, power supply voltage monitoring, and internal self-diagnosis, which automatically send fault location information to the HMI—reducing troubleshooting time by over 50%.

Harsh Environment Resilience and Ecosystem Integration: The **IS210AEBIH1ADC** adopts a reinforced housing design, compatible with NEMA 4X chassis for dustproof and waterproof protection in humid or corrosive environments (such as offshore platforms). It communicates with the Mark VIe backplane via GE’s high-speed proprietary protocol, synchronizing discrete data and diagnostic information with the **IS210MACCH1A** and HMI in real time. It supports advanced online configuration and fault simulation via Mark VIe Configuration Studio, enabling maintenance without system shutdown.

Typical Application Scenarios

In offshore wind-turbine power generation systems, the **IS210AEBIH1ADC** serves as the core discrete input module for the Mark VIe control system. It monitors 16 critical signals, including wind turbine yaw position switches, hydraulic brake status, generator temperature limit contacts, and emergency stop signals. Its -10°C low-temperature resistance adapts to offshore winter conditions, while 1000V AC isolation resists interference from wind turbine converters. When a generator over-temperature limit switch triggers, the module transmits the fault signal to the **IS210MACCH1A** in ≤0.5ms, prompting immediate shutdown to avoid equipment damage.

In petrochemical industry gas turbine systems, the **IS210AEBIH1ADC** monitors discrete signals from explosion-proof areas (ATEX Zone 2), including fuel gas valve position switches, flame detection contacts, and emergency shutdown valve status. Its ATEX certification ensures safe operation in flammable environments, while channel open/short detection quickly identifies wiring faults caused by corrosion. The module’s compatibility with both dry and wet contacts allows seamless integration with explosion-proof mechanical switches and active sensors in petrochemical plants.

In large-scale combined-cycle power plants, the **IS210AEBIH1ADC** collects discrete signals from gas-steam combined turbine systems, such as heat recovery steam generator (HRSG) valve limit switches, steam turbine governor status, and auxiliary pump running signals. Its 65°C high-temperature resistance adapts to the hot environment near HRSGs, while multi-layer EMI filtering resists interference from multiple generators. The module’s self-diagnostic function proactively alerts maintenance teams to potential faults, ensuring the continuous operation of the combined-cycle system with minimal unplanned downtime.

Related Model Recommendations

**IS210AEBIH2ADC**: 32-channel variant of **IS210AEBIH1ADC**, designed for large-scale Mark VIe systems (such as multi-turbine offshore power plants) requiring extended discrete signal monitoring.

**IS210MACCH1A**: Mark VIe control module that processes discrete data and diagnostic information from **IS210AEBIH1ADC**, executing precise protective actions for complex turbine systems.

**IS210BPPBH2BAP**: Enhanced Mark VIe power supply module with surge protection, providing stable 24V DC power to **IS210AEBIH1ADC** in harsh electrical environments.

**IS210BAPAH1ADC**: Analog input module with enhanced anti-interference performance, complementing **IS210AEBIH1ADC** to provide comprehensive turbine status monitoring in high-interference environments.

**IS210BDAOH1ADC**: Digital output module with explosion-proof certification, working with **IS210AEBIH1ADC** to execute discrete control commands (e.g., valve actuation) in hazardous areas.

**IC754VSF12CTD-EX**: Explosion-proof GE VersaMax HMI that displays real-time discrete status and diagnostic data from **IS210AEBIH1ADC**, suitable for on-site monitoring in hazardous areas.

**IS210MCCPG2A**: High-speed Mark VIe communication module that extends **IS210AEBIH1ADC**’s connectivity to remote SCADA systems, enabling real-time data transmission for offshore or distributed power plants.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210AEBIH1ADC**, power off the Mark VIe chassis and verify backplane compatibility. For hazardous areas, ensure the module is installed in a NEMA 4X explosion-proof enclosure. Use double-shielded twisted-pair cables (with armor for offshore applications) for sensor connections, and ground the cable shield at both ends to enhance anti-interference. Configure each channel’s input type (dry/wet contact), diagnostic thresholds, and fault alarm levels via Mark VIe Configuration Studio. Label wires clearly according to the turbine signal schematic, and perform insulation resistance testing (≥100MΩ at 500V DC) before power-on.

Maintenance suggestions: Conduct bi-monthly visual inspections of **IS210AEBIH1ADC**, checking for loose wiring, connector corrosion, and enclosure sealing integrity—clean the module with a dry anti-static cloth (avoid water in hazardous areas). Test each channel monthly using a precision signal simulator to verify response time (≤0.5ms) and input accuracy. Perform quarterly isolation resistance testing (≥100MΩ at 1000V DC) and EMI filtering performance checks. Update the module’s firmware semi-annually via GE’s secure technical support platform. For offshore applications, conduct additional corrosion resistance inspections every 6 months and replace shielded cables every 3 years if necessary.

Service and Guarantee Commitment

GE General Electric provides a 48-month quality guarantee for the **IS210AEBIH1ADC**, covering manufacturing defects, channel failures, isolation performance degradation, diagnostic function malfunctions, and EMI filtering failures under normal operating conditions. Our global technical support team offers 24/7 specialized services for harsh environment applications, including remote diagnostic analysis, on-site troubleshooting guidance, and customized configuration solutions. Customers receive exclusive access to GE’s advanced Mark VIe Configuration Studio tools, explosion-proof installation guidelines, and calibration documentation for the module. Priority service clients benefit from 24-hour emergency replacement of defective modules and dedicated technical account managers to ensure minimal downtime for critical turbine systems.