Description

Key technical specifications

- Model Number: IS200VTURH2Baxcontroler+1

- Manufacturer: General Electric – Mark VI Speedtronic familyunisysgroup

- Board Function: VME turbine card / primary turbine protection boardworldofcontrols

- Inputs – Speed: Up to four speed inputs from passive magnetic pickups (typically on shaft / gear teeth)worldofcontrols

- Inputs – Flame: Interfaces to Geiger‑Mueller flame detectors on gas turbines for flame presence monitoringaxcontroler

- Monitored Electrical Signals: Turbine shaft / generator voltage and current for protection and supervision functionsworldofcontrols

- Overspeed Trip: Can issue a trip command in turbines without a mechanical overspeed bolt, based on electronic speed processingaxcontroler

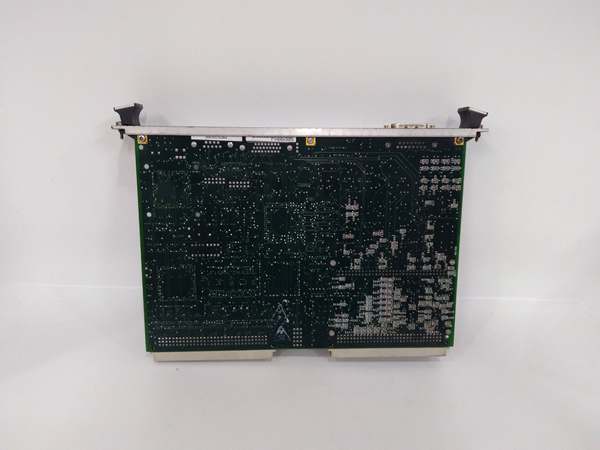

- Form Factor: Double‑wide VME board with auxiliary daughterboard, two VME backplane connectors, multiple front/back board connectorsworldofcontrols

- On‑board Electronics: Mix of FPGAs, oscillators, RAM/SRAM for high‑speed processing and event handlingthephoenixcontrols

- Indicators: Front faceplate with three status LEDs (typically RUN/FAIL/STATUS – exact labels vary by revision)axcontroler

- Mechanical: Double‑wide faceplate, board populated both sides with inductors, transistors, resistors, capacitors; designed for Mark VI VME rack slotsworldofcontrols

IS200VTURH2B

Field application & problem solved

Out in a turbine hall, the two things that will ruin your day fastest are overspeed and flame problems. Mechanical overspeed trips and simple flame scanners are fine until you want real diagnostics and consistent protection across a fleet. The IS200VTURH2B is the Mark VI answer to that: it centralizes overspeed and flame protection into a dedicated protection card with its own high‑speed processing and clear trip logic, instead of scattering that logic across relays and miscellaneous boards.unisysgroup

You’ll see this board in Mark VI panels for both steam and gas turbines. On steam units it is focused on shaft speed and voltage/current monitoring for overspeed and related protective actions. On gas turbines it adds the Geiger‑Mueller flame detector interface so the same card is watching that the flame actually exists where the logic thinks it should, not just trusting a start permissive bit. The speed pickups from the turbine shaft or gear ring come in as passive magnetic signals; this card does the conditioning, frequency calculation, and comparison to configured overspeed thresholds. When a configured limit is exceeded, or flame is lost when it shouldn’t be, the board has authority to issue a trip—even in units that have no mechanical overspeed bolt to fall back on.unisysgroup

The real value is that the dangerous stuff—overspeed and flame—is being measured and acted on in one designated, purpose‑built piece of hardware. That means you get consistent behavior from unit to unit, deterministic trip logic, and a single place to look when you’re trying to understand why a turbine came off‑line. Instead of chasing a halting combination of hard‑wired relays, separate flame panels, and speed relays, you have a single protection module integrated into the Mark VI system, with configuration and diagnostics visible from the HMI and tools. In a plant where every trip is expensive, that clarity is worth a lot.unisysgroup

Installation & maintenance pitfalls (expert tips)

Speed pickups are not generic proximity probes

The speed inputs expect passive magnetic pickups with the right air gap and tooth geometry. If someone swaps in a proximity probe or mis‑gaps the magnetic pickups, the card will see unstable or weak signals. That shows up as noisy calculated speed, spurious overspeed alarms, or loss‑of‑speed faults. Always verify pickup type, gap, and wheel condition before blaming the board—rusted teeth, missing teeth, or bent wheels will give you garbage frequency no matter how good the card is.axcontroler

Flame detector wiring is safety‑critical, not “just another analog”

On gas turbines, the Geiger‑Mueller flame detectors this board monitors are part of primary protection. Sloppy junction box terminations, shared neutrals with noisy loads, or running flame detector cabling along motor feeders is asking for nuisance flame‑loss trips. Wiring has to be clean, shielded where specified, and routed away from high EMI sources. If you see random flame‑loss events with no real combustion issue, start with the wiring path and connectors—not the logic configuration.worldofcontrols

Don’t override protection logic during troubleshooting without a plan

Because this card can issue a turbine trip, people get tempted to “bypass” speed or flame protections to get a start in under schedule pressure. That’s a good way to damage hardware or worse. If you absolutely must bypass for troubleshooting, it needs to be temporary, documented, and implemented through proper Mark VI tools and procedures, not lifted wires or jumpers at the rack. And you verify that all protections are restored and tested before handing the unit back to operations.automationindustrial

Check firmware, configuration, and hardware as a set

The card depends on correct configuration in the Mark VI toolbox files—speed pickup selection, overspeed setpoints, flame detector channels, and turbine‑specific trip logic. Swapping a board without checking that the downloaded configuration matches the turbine design is a common rookie mistake, leading to mismatched speed scaling or wrong trip limits. Any time you replace this board, confirm hardware revision compatibility and then verify configuration: speed scaling, limits, and channel mapping before doing any high‑speed test runs.automationindustrial

Use the front LEDs and diagnostic tools before pulling hardware

The front‑panel LEDs and Mark VI diagnostics will usually tell you if the card is actually unhealthy (self‑test/FAIL) or just not happy with what it’s seeing from the turbine (bad pickup, no flame, out‑of‑range speed). Too many times, people yank a card out because of an alarm when the root cause is a dead speed pickup or a disconnected flame detector. Pull up the diagnostic screens, look at raw speed and flame counts, and only then decide whether you have an instrument problem or a board problem.automationindustrial

IS200VTURH2B

Technical deep dive & overview

Inside the Mark VI rack, this board behaves like a dedicated protection cop for the turbine. Mechanical signals—the magnetic speed pickups on the shaft, the voltage and current coming from the generator or turbine circuit, and the pulses from Geiger‑Mueller flame detectors—are all terminated in the panel and then presented to this card through the backplane and harnessing. Onboard analog front‑ends condition these signals, and FPGAs plus timing hardware convert them into digital speed, flame, and electrical parameters at high sampling rates. That lets the card run protection logic with much finer timing than the general‑purpose sequencing logic that lives elsewhere in the system.thephoenixcontrols

The board presents its processed values and status back into the Mark VI control core over the VME backplane, but for overspeed and similar trips it doesn’t just “suggest” an action—it is allowed to assert trip commands directly in architectures where there is no mechanical overspeed bolt or where electronic protection is the primary layer. It also works with other protection‑related boards in the Mark VI (for example, vibration or thermocouple inputs in a full protection suite) to provide a coherent picture of turbine health. The double‑wide form factor gives it room for the additional daughterboard and timing hardware needed to do that job reliably. In practical terms, if you strip everything else away, this is the board that watches speed and flame hard enough that you can sleep at night when the unit is on the governor.automationindustrial