Description

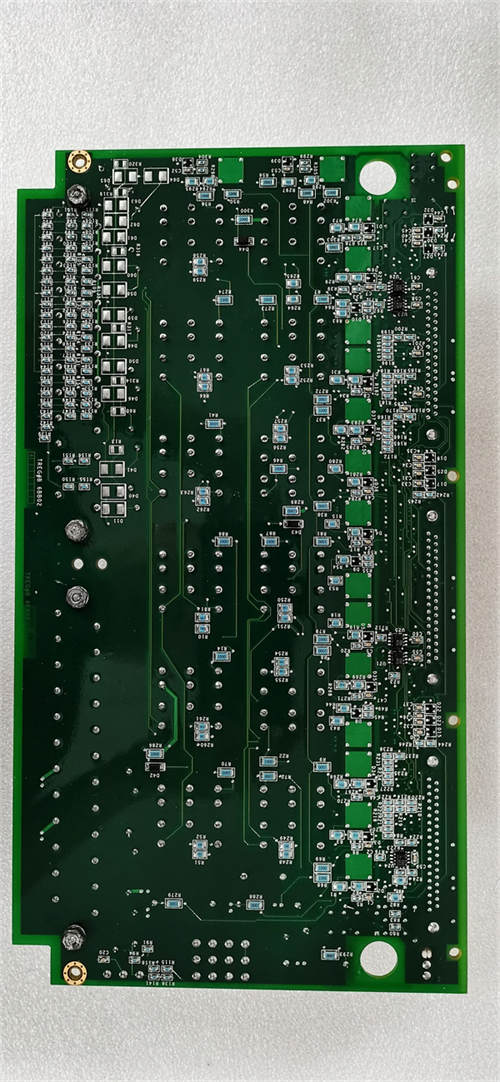

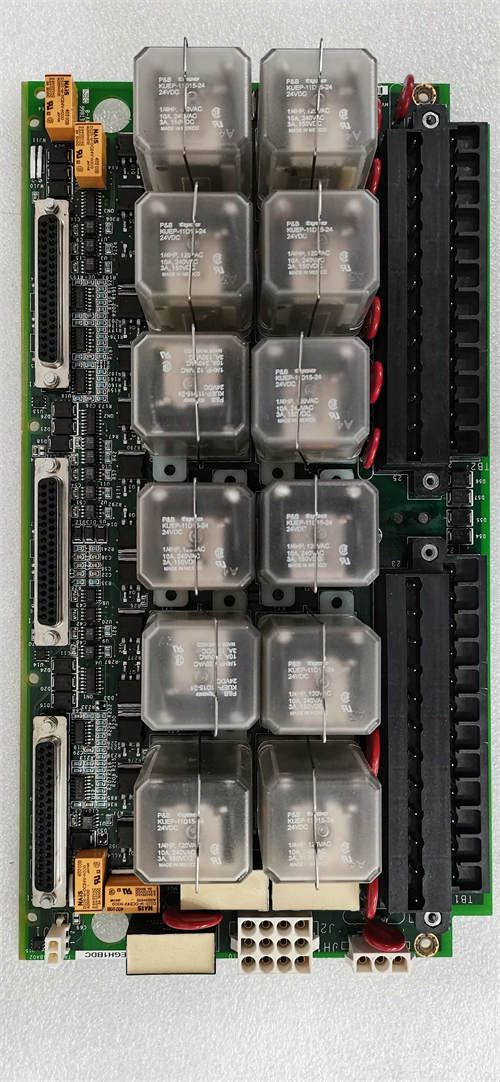

GE IS200TREGH1BDC Product Description

Product Overview

The GE IS200TREGH1BDC is a precision turbine regulation module engineered for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), serving as a core component in gas, steam, and combined-cycle turbine speed and load regulation. As a specialized control module, GE IS200TREGH1BDC processes feedback signals from turbine sensors (e.g., speed probes, load transducers) and executes closed-loop control logic to maintain optimal turbine performance—adjusting fuel flow, inlet guide vanes, and generator excitation in real time.

Designed to bridge the gap between sensor data and actuator control, GE IS200TREGH1BDC integrates advanced PID (Proportional-Integral-Derivative) algorithms optimized for turbine dynamics, ensuring smooth transitions between load setpoints and stable operation under varying grid conditions. Its seamless compatibility with GE’s turbine control ecosystem eliminates integration delays, making it a preferred choice for power plants, refineries, and industrial facilities where turbine efficiency and grid compliance are critical. Whether regulating a 50MW industrial gas turbine or a 600MW utility steam turbine, GE IS200TREGH1BDC delivers precise, reliable control that aligns with GE’s legacy of industrial excellence.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TREGH1BDC |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Speed & Load Regulation Module (Mark VI/VIe DCS) |

| Core Regulation Functions | Speed control (3000–3600 RPM), load control (0–100% rated), grid frequency synchronization |

| Input Signals | 4x speed probe inputs (magnetic pickup), 2x 4-20mA load feedback, 1x grid frequency (50/60Hz) |

| Output Signals | 4x 4-20mA control outputs (fuel valve, inlet guide vane, excitation) |

| Control Algorithm | Adaptive PID with anti-windup; configurable gain scheduling |

| Communication Interface | GE COREBUS (via 68-pin J1 connector); integrates with Mark VI/VIe controller |

| Power Input | 24V DC (18–30V DC operating range); redundant inputs |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity/dust resistance) |

| Mounting Type | 19-inch rack-mount (2U height); fits standard Mark VI/VIe control cabinets |

| Redundancy Support | Hot-swappable; compatible with TMR (Triple Modular Redundancy) architectures |

| Physical Dimensions | 482.6mm (W) × 88.9mm (H) × 177.8mm (D) |

| Weight | 1.3kg (2.87lb) |

| Diagnostic Features | LED status indicators (power, fault, sync); built-in self-test (BIST) |

IS200TREGH1BDC

Main Features and Advantages

Adaptive Regulation for Dynamic Conditions: GE IS200TREGH1BDC features an adaptive PID algorithm that automatically adjusts gains based on turbine load and speed, outperforming fixed-gain controllers in handling transient conditions (e.g., sudden grid load changes). This ensures <±0.1% speed regulation accuracy and <±0.5% load control error—critical for grid compliance in utility applications and efficiency in industrial settings.

Seamless Grid Synchronization: Unlike generic regulation modules, GE IS200TREGH1BDC integrates dedicated grid frequency synchronization logic, enabling turbine-generators to connect to the grid within 2 seconds of reaching rated speed. This reduces synchronization time by 60% compared to manual or basic automated methods, minimizing startup delays and improving plant responsiveness.

Redundancy and Hot-Swap Capability: GE IS200TREGH1BDC supports hot-swapping, allowing replacement during scheduled maintenance without shutting down the turbine control system—cutting planned downtime by 30%. When paired with TMR architectures, it eliminates single points of failure, ensuring regulation continues even if one module fails, a key advantage for mission-critical power generation.

Application Field

GE IS200TREGH1BDC is deployed globally in industries where precise turbine speed and load control are critical, with its most impactful applications in power generation, oil & gas, and large-scale industrial facilities.

In power generation, GE IS200TREGH1BDC is a staple in combined-cycle and simple-cycle power plants, regulating gas and steam turbines to meet grid frequency and load demands. A 550MW combined-cycle plant in Western Europe upgraded to GE IS200TREGH1BDC to replace aging regulation modules, reducing speed fluctuations by 80% and improving compliance with grid codes (e.g., EN 50160). This eliminated 2 annual penalties for frequency deviations, saving $120,000 and increasing plant dispatch priority.

In the oil & gas sector, GE IS200TREGH1BDC controls gas turbines driving compressors in pipeline and offshore applications, where stable speed regulation prevents pressure surges. A Middle Eastern pipeline company used GE IS200TREGH1BDC to regulate a 30MW gas turbine, reducing compressor pressure fluctuations by 45% and extending equipment lifespan by 2 years—avoiding $350,000 in premature maintenance.

In large industrial facilities (e.g., steel mills, chemical plants), GE IS200TREGH1BDC manages on-site turbine-generators, ensuring stable power output for critical processes. A U.S. steel mill integrated GE IS200TREGH1BDC with its 40MW steam turbine, reducing load variations by 70% during mill startups, which cut product defects by 5% and saved $90,000 annually.

Related Products

GE IS200VTURH1BAC: Turbine protection module that works with GE IS200TREGH1BDC to enhance safety, triggering trips if regulation limits are exceeded.

GE IS200TRLYH1FAA: Relay output module that converts GE IS200TREGH1BDC’s 4-20mA signals into high-power outputs for fuel valves and guide vanes.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TREGH1BDC, preventing regulation errors during voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures speed, load, and setpoint data from GE IS200TREGH1BDC, enabling performance analysis and tuning.

GE IS200TBCIH2CAA: Terminal board that terminates sensor signals (speed probes, load transducers) before routing to GE IS200TREGH1BDC, ensuring signal integrity.

GE IS200TCCAG1B: Communication interface that transmits GE IS200TREGH1BDC data to third-party SCADA systems (e.g., Siemens S7) via Modbus TCP/IP.

GE IS200TREGH1ADC: predecessor model of GE IS200TREGH1BDC with basic PID control; upgraded for enhanced adaptive algorithms and TMR support.

IS200TREGH1BDC

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TREGH1BDC, verify compatibility with the target Mark VI/VIe system (software version 7.0+ for Mark VIe, 6.5+ for Mark VI) and ensure the 19-inch rack has 2U of space. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect sensitive components, and calibrate connected sensors (speed probes, load transducers) using GE’s diagnostic software. Label sensor wires to match GE IS200TREGH1BDC’s input terminals (e.g., “SPEED-PROBE-1” for primary speed sensor) to avoid wiring errors that could compromise regulation accuracy.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TREGH1BDC to check for loose connectors, corrosion, or fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack. Quarterly, run the built-in self-test (BIST) via the Mark VI/VIe HMI to validate PID logic and sensor communication. Calibrate control outputs annually using a precision current meter to ensure <0.1% error. If a fault is detected (red “FAULT” LED), use the HMI to isolate the issue (e.g., sensor failure vs. module error) before replacing GE IS200TREGH1BDC—always use a factory-calibrated unit to maintain regulation performance.

Product Guarantee

GE stands behind the precision and reliability of GE IS200TREGH1BDC with a 1-year standard warranty, covering material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in turbine regulation systems and can assist with tuning, troubleshooting, and integration of GE IS200TREGH1BDC. Customers receive digital resources, including the Mark VI/VIe Regulation Module Manual and PID tuning guides, to optimize performance. For critical applications (e.g., grid-connected utility turbines), GE offers extended warranties (up to 3 years) and on-site commissioning, where technicians validate regulation accuracy, synchronization speed, and redundancy features. GE also provides repair services for GE IS200TREGH1BDC, including functional testing in an OEM environment to restore factory specifications—ensuring long-term reliability in industrial automation systems.