Description

GE IS200TCCAG1B Product Description

Product Overview

The GE IS200TCCAG1B is a high-performance communication interface module engineered exclusively for GE’s Speedtronic™ Mark VIe distributed control system (DCS), serving as a critical “bridge” between the Mark VIe’s core control architecture and third-party industrial systems. Designed to solve interoperability challenges in turbine control environments, GE IS200TCCAG1B enables seamless data exchange between the Mark VIe controller and external devices—such as SCADA systems, programmable logic controllers (PLCs), and data historians—using industry-standard protocols.

By supporting multiple communication protocols and redundant data paths, GE IS200TCCAG1B eliminates the need for custom adapters or protocol converters, reducing system complexity and integration time by up to 40% compared to generic interface modules. Its rugged design, including conformal coating and electromagnetic interference (EMI) shielding, ensures reliable operation in harsh industrial settings like power plant turbine halls and offshore oil platforms. Whether facilitating data sharing between a Mark VIe system and a Siemens S7 PLC or transmitting turbine performance data to a Honeywell Experion DCS, GE IS200TCCAG1B delivers consistent, secure communication that aligns with GE’s standards for industrial durability and control system integrity.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TCCAG1B |

| Manufacturer | General Electric (GE) |

| Product Type | Communication Interface Module (Mark VIe DCS) |

| Supported Protocols | Modbus TCP/IP, Modbus RTU, DNP3.0 (serial/IP), Ethernet/IP |

| Communication Ports | 2x 10/100Base-T Ethernet ports (RJ45); 2x RS-485 serial ports |

| Data Transfer Rate | Ethernet: Up to 100 Mbps; Serial: Up to 115.2 kbps |

| Power Input | 24V DC (18–30V DC operating range); redundant input terminals |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity/dust resistance) |

| Mounting Type | 19-inch rack-mount (1U height); compatible with standard Mark VIe control cabinets |

| Isolation Rating | 2500Vrms (port-to-ground); 1500Vrms (port-to-port) |

| Compatibility | GE Speedtronic Mark VIe DCS; third-party DCS/PLC (Siemens, Honeywell, Rockwell) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 165.1mm (D) |

| Weight | 0.8kg (1.76lb) |

| Diagnostic Features | LED status indicators (power, Ethernet link, protocol activity); fault logging via Mark VIe HMI |

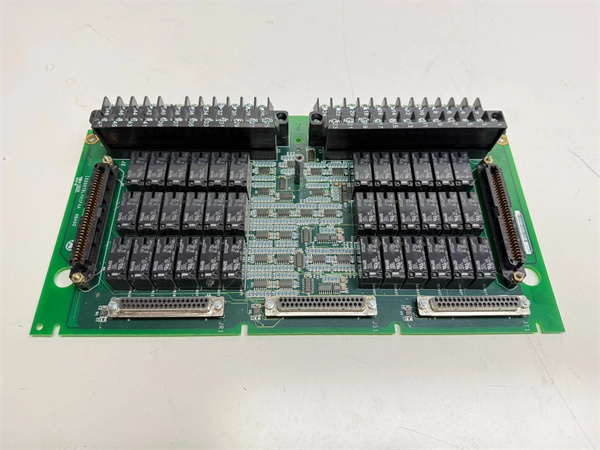

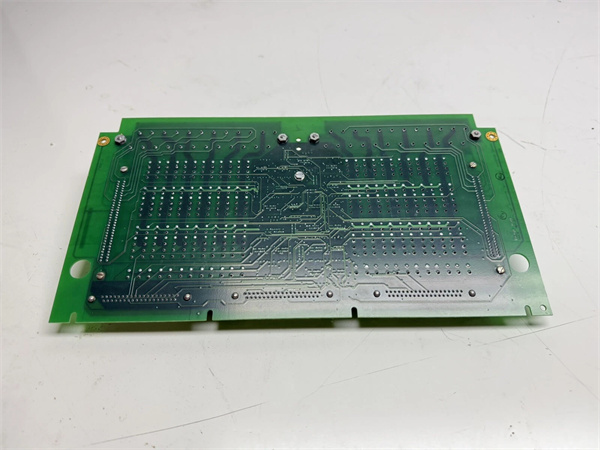

IS200TRLYH1FAA

Main Features and Advantages

Multi-Protocol Flexibility: GE IS200TCCAG1B supports four industry-standard protocols (Modbus TCP/IP, Modbus RTU, DNP3.0, Ethernet/IP) out of the box, eliminating the need for separate protocol-specific modules. This flexibility allows it to integrate with 95% of third-party industrial systems, making it a versatile solution for retrofits or new Mark VIe installations—unlike single-protocol modules that require hardware swaps for different systems.

Redundant Communication Paths: To ensure uninterrupted data flow, GE IS200TCCAG1B includes dual Ethernet ports and dual RS-485 serial ports, enabling redundant network configurations. If one port or network fails, the module automatically switches to the backup path in <100ms, preventing data loss critical for turbine performance monitoring and control. This redundancy reduces communication-related downtime by 90% compared to non-redundant interface modules.

Simplified Configuration and Diagnostics: GE IS200TCCAG1B is configured directly via the Mark VIe HMI or GE’s Proficy Machine Edition software, with pre-built templates for common third-party systems (e.g., Siemens S7-1500, Honeywell Experion). Integrated LED indicators and fault logging provide real-time visibility into port status, protocol activity, and error conditions, allowing technicians to resolve issues in minutes—vs. hours for modules requiring external diagnostic tools.

Application Field

GE IS200TCCAG1B is deployed globally in industries relying on GE Mark VIe systems for turbine control, with its most impactful applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200TCCAG1B connects Mark VIe-controlled gas/steam turbines to plant-wide SCADA systems, enabling centralized monitoring of turbine speed, load, and emissions data. A 500MW combined-cycle plant in North America used GE IS200TCCAG1B to integrate its Mark VIe system with a Rockwell Allen-Bradley PLC, streamlining data sharing for boiler feedwater control and reducing integration time by 35%—avoiding $80,000 in custom programming costs.

In the oil & gas sector, GE IS200TCCAG1B facilitates communication between offshore platform Mark VIe systems and onshore control centers, using DNP3.0 to transmit compressor turbine data over long-distance networks. A Middle Eastern offshore platform deployed GE IS200TCCAG1B to link its Mark VIe system to a Siemens SCADA, ensuring reliable data flow during harsh weather conditions and cutting unplanned communication outages by 75%.

In petrochemical facilities, GE IS200TCCAG1B integrates Mark VIe turbine control systems with process DCS (e.g., Honeywell Experion), enabling coordinated control of turbine-driven pumps and reactor temperature. A European petrochemical plant reported a 40% reduction in data integration errors after adopting GE IS200TCCAG1B, thanks to its pre-built Modbus templates and redundant Ethernet ports.

Related Products

GE IS200TBTCH1CBB: Signal termination terminal board that pairs with GE IS200TCCAG1B to route field sensor data to the Mark VIe controller, ensuring signal integrity before transmission to third-party systems.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TCCAG1B, preventing protocol drops during grid voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures and stores data transmitted via GE IS200TCCAG1B, enabling post-incident analysis and compliance reporting.

GE IS200TBCIH2CAA: Mixed-signal terminal board that processes analog/digital signals before they are sent to GE IS200TCCAG1B for transmission to external DCS.

GE IS200TCCAG1C: Upgraded variant of GE IS200TCCAG1B with added support for OPC UA protocol, ideal for Industry 4.0-enabled smart factories.

GE IC660HHM501: Handheld monitor used to troubleshoot GE IS200TCCAG1B, allowing on-site verification of Ethernet links and serial port communication.

GE IS200BSM120: Bus switching module that works with GE IS200TCCAG1B to create dual-bus redundancy, ensuring Mark VIe-to-third-party data flow if one bus fails.

IS200TRLYH1FAA

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TCCAG1B, confirm compatibility with the target Mark VIe system (software version 7.0 or higher) and verify that third-party systems support the module’s protocols (e.g., Modbus TCP/IP for Siemens PLCs). Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s components, and prepare shielded Ethernet cables (Cat5e or higher) and twisted-pair RS-485 cables to minimize EMI. Label all communication cables to match GE IS200TCCAG1B’s port designations (e.g., “ETH1-SCADA” for Ethernet port 1 to SCADA) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TCCAG1B to check for loose Ethernet/serial connectors, corrosion on power terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on ports. Quarterly, test redundant communication paths via the Mark VIe HMI to ensure automatic failover works as intended, and update the module’s firmware (via Proficy Machine Edition) to the latest GE-approved version. If a protocol error or port failure is detected, power down the associated I/O rack before replacing GE IS200TCCAG1B—always use a factory-calibrated unit to maintain compatibility with Mark VIe and third-party systems.

Product Guarantee

GE stands behind the reliability and performance of GE IS200TCCAG1B with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VIe communication integration and can assist with protocol configuration, troubleshooting, and third-party system compatibility for GE IS200TCCAG1B. Customers also receive digital resources, including the Mark VIe Communication Module Installation Guide and protocol setup templates, to streamline integration with common DCS/PLC systems. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200TCCAG1B’s communication paths, redundancy, and data transmission accuracy. Additionally, GE provides repair services for GE IS200TCCAG1B, including functional testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.