Description

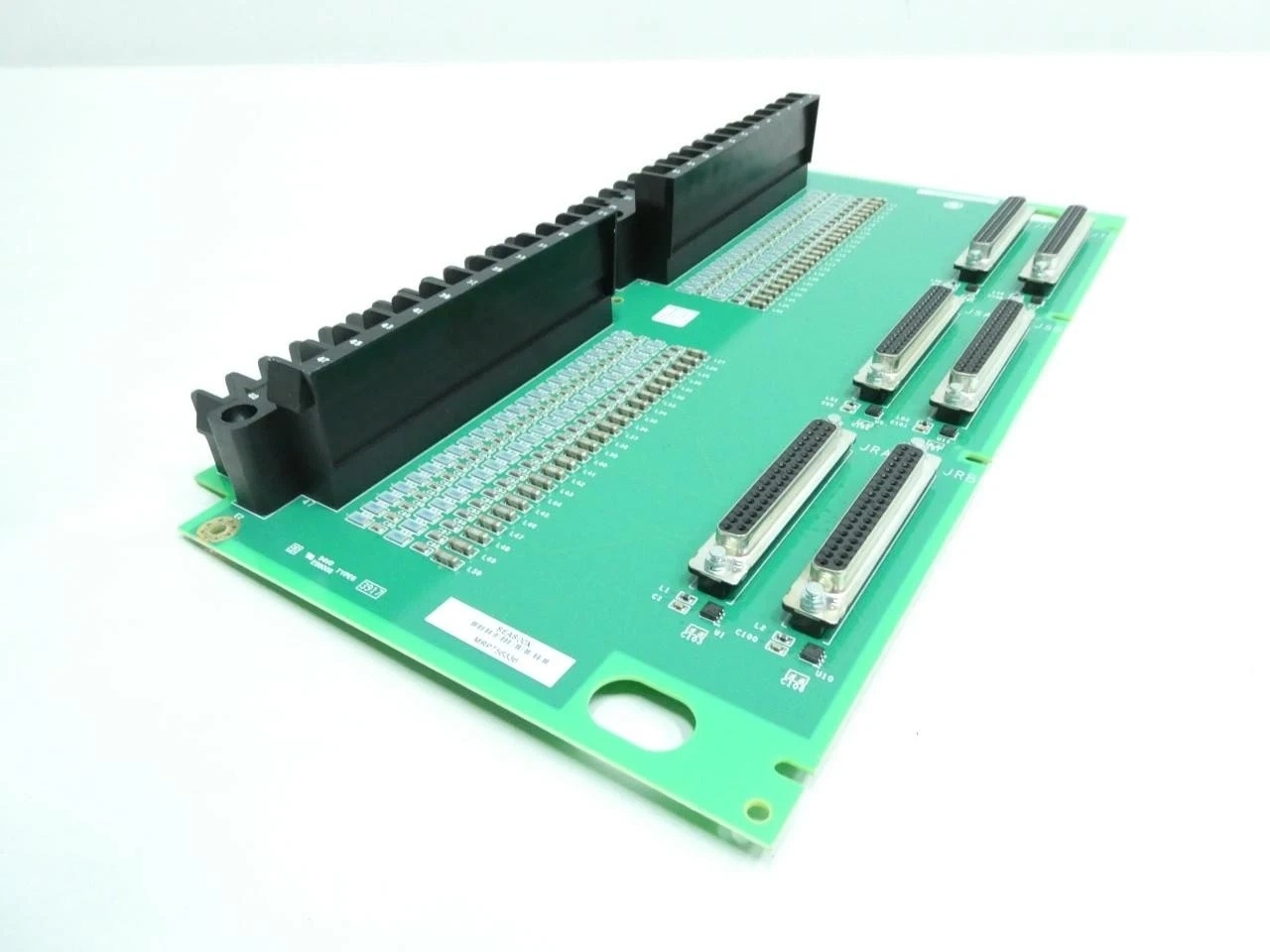

GE IS200TBTCH1BBB Turbine Control Terminal Board

Product Overview

The IS200TBTCH1BBB is a high-reliability turbine control terminal board developed by GE for the Mark VIe distributed control system, specifically engineered to serve as a critical interface between the turbine control logic and field devices. As a core component of the Mark VIe turbine control platform, IS200TBTCH1BBB integrates signal conditioning, terminal connection, and fault isolation functions, enabling stable transmission of analog and digital signals between the Mark VIe controller and turbine sensors/actuators. It is widely used in gas, steam, and combined-cycle turbine control systems, acting as a “signal bridge” to ensure precise and reliable turbine operation.

What makes IS200TBTCH1BBB indispensable is its ability to adapt to the harsh operating environment of power plants while maintaining high signal integrity. It effectively suppresses electromagnetic interference from turbine generators and high-voltage equipment, ensuring accurate signal transmission even in environments with strong vibration and voltage fluctuations. Its modular design and compatibility with GE’s Turbine Control System (TCS) software make it easy to integrate into both new turbine control systems and Mark VI to Mark VIe upgrade projects, significantly improving the maintainability and scalability of turbine control systems.

Technical Specifications

Parameter Name | Parameter Value ———|——– Product Model | IS200TBTCH1BBB Manufacturer | GE (General Electric) Product Type | Mark VIe Series Turbine Control Terminal Board Signal Type | Analog input/output, digital input/output Analog Input Range | 4-20 mA DC, 0-10 V DC Digital I/O Voltage | 24 V DC (sinking/sourcing configurable) Number of Terminals | 48 screw terminals (24 pairs for signal routing) Isolation Level | 2.5 kV AC between signal circuits and ground Operating Temperature | 0°C to +65°C (32°F to +149°F) Storage Temperature | -40°C to +85°C (-40°F to +185°F) Power Consumption | < 5 W (typical) Physical Dimensions | 152.4 mm (L) × 101.6 mm (W) × 25.4 mm (D) Mounting | DIN rail or backplane mount (compatible with IS200RACK01A) Certifications | UL 61010-1, CE, IEC 61326-1, RoHS 2.0

IS200TBTCH1BBB

Main Features and Advantages

Superior signal integrity: IS200TBTCH1BBB adopts a multi-layer PCB design with dedicated grounding and shielding layers, effectively reducing crosstalk between analog and digital signals. The built-in signal conditioning circuit filters out high-frequency noise (50/60 Hz interference suppression ≥ 40 dB), ensuring that the 4-20 mA analog signals from turbine vibration sensors and temperature transmitters are transmitted to the controller with an error of less than ±0.1%. This precision is crucial for turbine speed regulation and load control, directly improving the turbine’s operating efficiency.

Robust fault isolation: Each signal channel of IS200TBTCH1BBB is equipped with independent transient voltage suppressors (TVS) and current-limiting resistors, which can withstand 2.5 kV AC isolation voltage and 10 kV ESD pulses. In the event of a field short circuit or overvoltage fault, the board quickly cuts off the faulty channel to prevent damage to the core Mark VIe controller—reducing the risk of control system failure by over 80% compared to non-isolated terminal boards.

Easy installation and maintenance: IS200TBTCH1BBB features a plug-in modular design that allows hot-swapping during system operation (with proper safety measures), minimizing downtime for maintenance. The 48 screw terminals are clearly labeled with signal types and channel numbers, and the color-coded wiring guides simplify field wiring work, reducing wiring errors by 60% during commissioning. It is fully compatible with GE’s TCS configuration software, enabling remote monitoring of board status and signal health.

Broad compatibility: IS200TBTCH1BBB seamlessly integrates with various components of the Mark VIe system, including the IS200CPUH1AAA controller, IS200IOCCH1A input/output module, and IS200EXCH1A communication module. It also supports retrofitting in Mark VI systems with the use of the IS200MARKUP adapter, making it a cost-effective solution for power plants upgrading their turbine control systems without replacing the entire hardware platform.

Application Field

In gas turbine power plants, IS200TBTCH1BBB serves as the key interface for connecting the Mark VIe controller to critical turbine components. A 600 MW gas turbine power plant in the Middle East uses IS200TBTCH1BBB to route signals from 12 vibration sensors, 8 temperature transmitters, and 6 fuel control valves. The board’s strong anti-interference capability ensures stable transmission of vibration signals (up to 1000 Hz sampling rate) to the controller, enabling real-time monitoring of turbine shaft vibration and timely adjustment of fuel supply—reducing unplanned shutdowns caused by vibration anomalies by 90%.

In combined-cycle power plants, IS200TBTCH1BBB coordinates the control of gas and steam turbines. A 1,000 MW combined-cycle plant in Europe deploys 8 IS200TBTCH1BBB boards to integrate signals from both turbine systems, including steam pressure sensors, exhaust temperature transmitters, and speed governors. The board’s fault isolation function prevents a short circuit in the steam turbine’s oil pressure sensor from affecting the gas turbine control loop, ensuring the combined-cycle system operates in synergy and improving overall plant efficiency by 3%.

In industrial steam turbine applications (such as petrochemical plants), IS200TBTCH1BBB adapts to the harsh environment of high temperature and heavy vibration. A petrochemical plant in China uses IS200TBTCH1BBB to control a 50 MW steam turbine driving a centrifugal compressor. The board’s 2.5 kV isolation level withstands the interference from the plant’s high-voltage power grid, and its stable signal transmission ensures precise control of the turbine’s speed (speed regulation accuracy ±0.1 rpm), avoiding production interruptions caused by compressor speed fluctuations.

Related Products

IS200TBTCH2BBB: A dual-channel enhanced version of IS200TBTCH1BBB, supporting 96 terminals for large-scale turbine control systems with more signal channels.

IS200CPUH1AAA: Mark VIe main controller that pairs with IS200TBTCH1BBB, processing the signals transmitted by the terminal board to execute turbine control logic.

IS200RACK01A: Mark VIe 10-slot rack that houses IS200TBTCH1BBB and other control modules, providing mechanical support and backplane communication.

IS200IOCCH1A: Analog/digital I/O module compatible with IS200TBTCH1BBB, converting field signals into digital data for the controller.

IS200EXCH1A: Ethernet communication module that works with IS200TBTCH1BBB, transmitting terminal board status data to the plant’s SCADA system.

IS200MARKUP: Adapter module for IS200TBTCH1BBB, enabling its integration into legacy Mark VI turbine control systems.

GE TCS Software: Configuration and monitoring software for IS200TBTCH1BBB, supporting signal calibration, fault diagnosis, and remote configuration.

IS200CABL001: Shielded signal cable for IS200TBTCH1BBB, reducing electromagnetic interference during field signal transmission.

IS200TBTCH1BBB

Installation and Maintenance

Pre-installation preparation: Before installing IS200TBTCH1BBB, confirm that the Mark VIe rack (e.g., IS200RACK01A) has an available slot and that the backplane firmware is compatible (version ≥v7.0). Check the ambient environment: temperature 0°C to +65°C, humidity 5%-95% non-condensing, and avoid direct exposure to turbine exhaust heat. Prepare tools including a torque screwdriver (0.5-1.0 N·m), multimeter, and anti-static wristband. Power off the rack during installation, align the module with the slot guides, insert until fully seated, and secure with the front latch.

Maintenance recommendations: Conduct weekly visual inspections of IS200TBTCH1BBB, checking for loose terminals and damaged wiring. Monthly, use TCS software to calibrate analog signal channels and verify isolation resistance (≥100 MΩ between channels). Every 6 months, clean the terminal board with a dry brush to remove dust, and retighten the screw terminals (torque to 0.8 N·m) to prevent poor contact due to vibration. If a signal fault occurs, use the software’s diagnostic function to locate the faulty channel; replace the board with a genuine GE spare part if the isolation circuit fails.

Product Guarantee

GE provides a 24-month quality warranty for IS200TBTCH1BBB, covering manufacturing defects, signal isolation failures, and terminal damage under normal operating conditions. During the warranty period, GE offers free repair or replacement within 72 hours of receiving a valid fault report, with expedited shipping for power plant customers to minimize downtime. Our professional technical team provides on-site installation guidance and training, and 24/7 remote support for fault diagnosis. Extended warranty options (up to 4 years) include annual on-site calibration and performance testing, reflecting GE’s commitment to the reliability of turbine control systems and customer operational continuity.