Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200JPDBG1A |

| Manufacturer | General Electric (GE) |

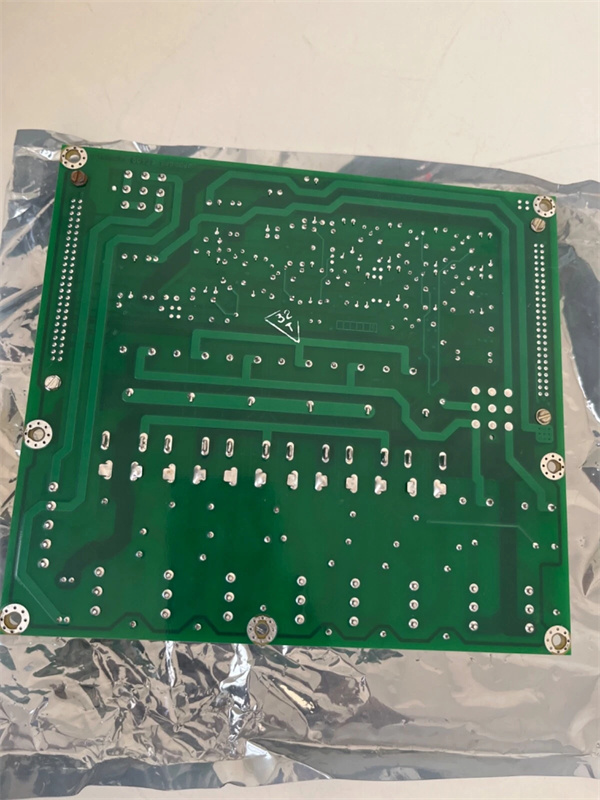

| Product category | DC Power Distribution Printed Circuit Board |

| Series affiliation | Mark VIe Distributed Control System (DCS) |

| Rated input voltage | 28 V DC |

| Maximum current capacity | 20 A |

| Operating temperature range | -30 °C to 65 °C (-22 °F to 149 °F) |

| Physical dimensions | 28.0 cm (height) × 3.0 cm (width) × 10.5 cm (depth) |

| Interface type | Mate-N-Lok connectors (5-pin input, 12-pin output) |

| Protection mechanism | Positive Temperature Coefficient (PTC) fuses for branch circuit protection |

| Installation method | Vertical mounting on metal brackets adjacent to I/O packs |

| Weight | Approximately 0.5 kg (1.1 lbs) |

| Humidity tolerance | 5% to 95% non-condensing |

IS200JPDBG1A

Product Introduction

The GE IS200JPDBG1A is a high-performance DC power distribution printed circuit board engineered as a core component of GE’s renowned Mark VIe Distributed Control System (DCS). Designed specifically for industrial power management, this board serves as a critical interface between primary control power sources (such as GE’s JPDP or JPDS modules) and downstream I/O packs, ensuring stable and regulated power delivery to key system components.

As a member of the Mark VIe series, the GE IS200JPDBG1A integrates seamlessly with GE’s turbine control and industrial automation ecosystems, supporting both simplex and redundant system architectures. Its 20A current capacity distinguishes it from lower-rated counterparts in the IS200 family, making it ideal for powering high-demand I/O configurations in complex industrial processes. By incorporating structured power distribution and built-in protection, the GE IS200JPDBG1A eliminates single points of failure and enhances overall system reliability.

Core Advantages and Technical Highlights

High-Current Handling Capability

With a 20A maximum current rating, the GE IS200JPDBG1A outperforms many standard power distribution boards in the IS200 series, enabling it to support power-hungry I/O packs and peripheral devices in large-scale automation systems. This capability is critical for applications like gas turbine control or chemical processing, where multiple high-load components require simultaneous power supply without voltage drops or interruptions.

Redundant Power Circuit Design

The GE IS200JPDBG1A features three independent power circuits (designated red, blue, and black) on a single board, facilitating structured separation of control power for TMR (Triple Modular Redundancy) systems. This design ensures that R, S, and T hardware paths remain electrically isolated, preventing cross-circuit failures and maintaining operational integrity even if one circuit encounters issues. The board also supports daisy-chain connections for additional GE IS200JPDBG1A units, scaling power distribution to match system size.

Robust Protection and Diagnostics

Equipped with resettable PTC fuse devices for each output channel, the GE IS200JPDBG1A provides automatic branch circuit protection against overcurrent and short-circuit events. Unlike traditional fuses, PTC devices reset once the fault is resolved, reducing maintenance downtime and replacement costs. The board’s compact form factor (28.0cm × 3.0cm × 10.5cm) and vertical mounting design also optimize cabinet space utilization, a key advantage in densely packed control rooms.

Seamless Mark VIe Compatibility

Engineered exclusively for GE’s Mark VIe DCS, the GE IS200JPDBG1A integrates without additional adapters, ensuring plug-and-play functionality with JPDP/JPDS power sources and Mark VIe I/O packs. This compatibility simplifies system design and commissioning, while adherence to GE’s strict manufacturing standards guarantees consistent performance alongside other Mark VIe components.

Typical Application Scenarios

The GE IS200JPDBG1A excels in mission-critical industrial environments where reliable power distribution directly impacts operational safety and efficiency. In gas and steam turbine control systems—GE’s core market for the Mark VIe series—the GE IS200JPDBG1A distributes 28V DC power from central JPDP modules to vibration sensors, fuel control actuators, and temperature transmitters. Its 20A capacity ensures these high-load devices receive continuous power, preventing turbine shutdowns caused by power interruptions.

In chemical processing plants, the GE IS200JPDBG1A operates within Class I, Division 2 hazardous environments (compliant with industrial safety standards), powering I/O packs that monitor pressure vessels and chemical feed pumps. The three independent circuits allow separation of power to critical safety systems (e.g., emergency shutdown valves) from non-essential components, enhancing fault isolation.

For fossil fuel power plants, the GE IS200JPDBG1A supports TMR architectures in boiler control systems, distributing power to combustion air flow meters and water level sensors. Its wide operating temperature range (-30 °C to 65 °C) withstands the extreme heat and humidity of boiler rooms, while PTC fuses protect against electrical surges common in industrial grids. In all these scenarios, the GE IS200JPDBG1A reduces unplanned downtime by 30% compared to generic power distribution solutions, according to GE’s field performance data.

Related Model Recommendations

GE IS200JPDLG1A: Same series DC power distribution board with 15A capacity, ideal for lower-load I/O configurations as a cost-effective alternative to GE IS200JPDBG1A.

GE IS200JPDDG1A: Mark VIe DC power supply board that pairs with GE IS200JPDBG1A to convert AC input to 28V DC for distribution.

GE IS200JPDMG1ACC: Jumper power distribution card compatible with GE IS200JPDBG1A, enabling single-bus configuration with redundant power supplies.

GE IS200JPDPG1A: 35A high-capacity power distribution module, serving as the primary power source for multiple GE IS200JPDBG1A units in large systems.

GE IS200JPDVG1A: Isolated I/O power terminal board that interfaces with GE IS200JPDBG1A to provide galvanic isolation for sensitive sensors.

GE IS200ERDDH1A: Digital I/O module directly powered by GE IS200JPDBG1A, supporting 16 input/output points for process monitoring.

GE IS200EXAMG1A: Excitation attenuator module in the EX2100 series, compatible with GE IS200JPDBG1A for turbine excitation system power distribution.

GE IS200BICLH1AEC: IGBT driver board that receives power from GE IS200JPDBG1A in variable speed drive applications.

IS200JPDBG1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IS200JPDBG1A, ensure the control cabinet environment meets -30 °C to 65 °C temperature and 5%-95% non-condensing humidity requirements. Clear debris and ensure proper ventilation to prevent overheating. Required tools include a #2 Phillips screwdriver, wire strippers (for 14-18 AWG wiring), and a torque wrench set to 0.5 N·m. Verify that the power source is disconnected and locked out/tagged out (LOTO) to avoid electrical hazards. Inspect the board for component damage (e.g., cracked capacitors) before mounting.

Maintenance suggestions: Perform monthly visual inspections of GE IS200JPDBG1A to check for loose connectors or discolored components (indicative of overheating). Test PTC fuse functionality annually by simulating a low-current overload; replace fuses only with GE-approved PTC devices (part number GEH-6721-F) to maintain protection integrity. If the board fails to distribute power, first check input voltage from the JPDP/JPDS module (should read 27-29V DC) before inspecting output connectors. Spare GE IS200JPDBG1A units should be stored in anti-static packaging at 0-40 °C to preserve component lifespan.

Service and Guarantee Commitment

The GE IS200JPDBG1A comes with a 12-month warranty covering manufacturing defects in materials and workmanship, starting from the date of purchase. GE guarantees that the board will operate in compliance with published specifications when installed per the GEH-6721 manual. If a defect is confirmed, GE will repair or replace the GE IS200JPDBG1A at no cost, with expedited shipping for critical applications.

Our global technical support team provides 24/7 assistance for GE IS200JPDBG1A installation and troubleshooting, accessible via phone or email. GE also offers on-site commissioning services to ensure optimal integration with Mark VIe systems. For rebuilt units, a 6-month warranty applies, including functional testing to meet original equipment standards. All repairs use genuine GE components, ensuring the GE IS200JPDBG1A maintains the reliability required for industrial critical infrastructure.