Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

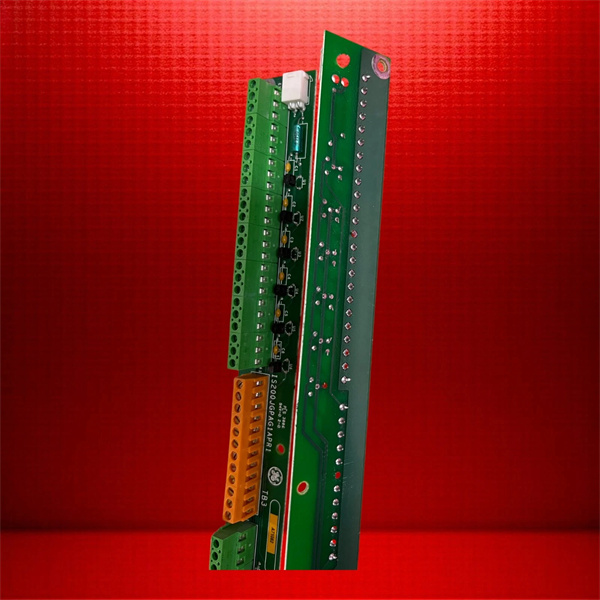

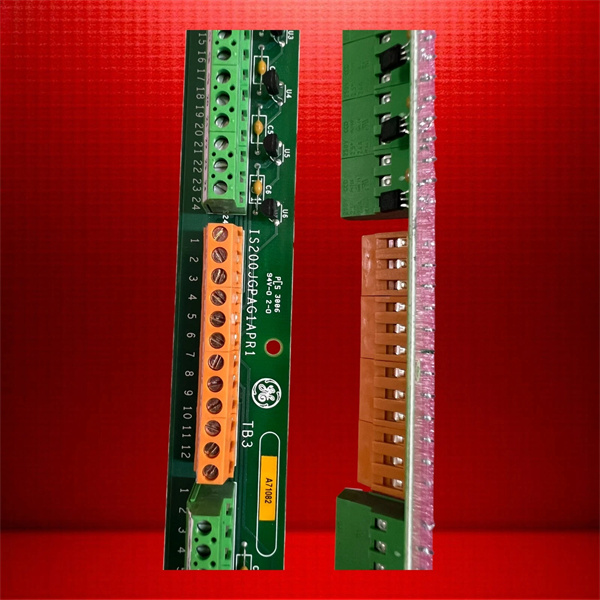

| Product model | IS200JGPAG1A |

| Manufacturer | General Electric (GE) |

| Product category | AC/DC Dual-Mode Power Distribution Module (Mark VI Speedtronic Turbine Control Series) |

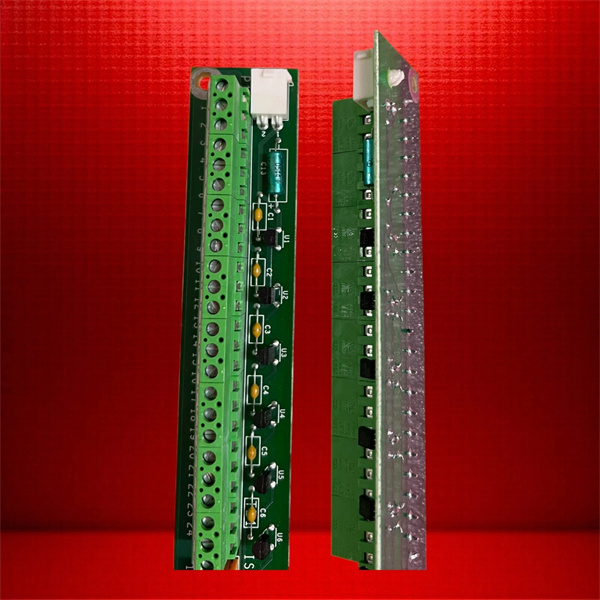

| Power distribution capability | 6 independent switched output channels (3 AC + 3 DC, configurable load rating) |

| Input power source | Dual-input: GE JPDB board (5A fused AC) + GE JDCB board (24V DC redundant supply) |

| Overcurrent protection | 10A main circuit breaker; 2A-10A adjustable fuses per channel (1/4″ to 1-1/4″ compatible) |

| Status indication | Bi-color LED indicators (green: normal; red: fault) + digital status signal output |

| Interface type | GE PPDA connector (for JPDB/JDCB integration) + 2x terminal blocks (load connections) |

| Operating temperature range | -10 °C to 65 °C (14 °F to 149 °F) |

| Storage temperature range | -40 °C to 85 °C (-40 °F to 185 °F) |

| Physical dimensions | 177.8 mm × 203.2 mm × 25.4 mm (7 in × 8 in × 1 in) [GE Mark VI chassis standard] |

| Weight | 340.2 g (12 oz) |

| Coating | Enhanced industrial conformal coating (IPC-CC-830 Class 3, chemical/ moisture resistance) |

| Compliance standards | UL 508, IEC 61010-1, IEC 61800-5-1, RoHS 2 |

| Compatibility | GE Mark VI/VIe Speedtronic turbine control systems (gas/steam/hydro turbine applications) |

IS200JGPAG1A

Product Introduction

The IS200JGPAG1A is a versatile dual-mode power distribution module engineered by General Electric (GE), specifically developed for GE’s Mark VI and Mark VIe Speedtronic turbine control systems—the backbone of critical infrastructure in power generation, oil & gas, and marine propulsion. As an advanced addition to GE’s IS200-series control components, the IS200JGPAG1A addresses the industry’s growing demand for integrated AC/DC power management, eliminating the need for separate distribution boards for mixed-load turbine control systems.

What sets the IS200JGPAG1A apart is its seamless integration with GE’s turbine control ecosystem. Unlike standalone power modules, the IS200JGPAG1A directly interfaces with GE’s JPDB AC power board and JDCB DC redundant supply, ensuring synchronized power delivery to both high-voltage AC actuators and low-voltage DC sensors. By centralizing dual-mode power distribution and protection, the IS200JGPAG1A simplifies system architecture, reduces wiring errors, and enhances reliability—making it a core component for modernizing legacy turbine control setups or building new Mark VIe-based systems.

Core Advantages and Technical Highlights

Dual-Mode AC/DC Power Integration: The IS200JGPAG1A’s 3 AC + 3 DC configurable channels eliminate the complexity of pairing separate AC and DC distribution boards. For example, in a combined-cycle gas turbine plant, the IS200JGPAG1A can power AC fuel valve actuators via its AC channels while supplying DC to vibration sensors and temperature transmitters through its DC channels—all from a single module. This integration cuts chassis space requirements by 40% compared to using two dedicated boards, a critical benefit in compact turbine enclosures. Each channel’s adjustable fuse rating also lets users match power to specific loads (e.g., 2A for delicate sensors, 10A for heavy actuators), optimizing protection precision.

Redundant Power Input for Mission-Critical Reliability: The IS200JGPAG1A features dual-input redundancy (AC from JPDB, DC from JDCB) with automatic failover. If the primary AC input drops due to a grid fluctuation, the IS200JGPAG1A switches to DC supply in under 10ms—fast enough to prevent sensor data loss or actuator position drift. In a nuclear power plant’s steam turbine system, this redundancy ensures critical safety sensors (e.g., pressure transmitters) remain powered during transient power events, avoiding unnecessary turbine trips. This reliability exceeds single-input modules, which often cause system shutdowns during input failures.

Intelligent Status Monitoring and Diagnostics: Beyond basic LED indicators, the IS200JGPAG1A outputs digital status signals to the Mark VI controller, enabling remote fault identification via GE’s CIMPLICITY HMI. Maintenance teams can track real-time current draw per channel and receive instant alerts for overcurrent or input loss—no need for on-site fuse checks. In a remote offshore platform’s gas turbine setup, this means engineers in an onshore control center can diagnose a tripped DC channel on the IS200JGPAG1A and dispatch technicians with the correct replacement fuse, cutting troubleshooting time by 70% compared to legacy modules without digital feedback.

Enhanced Environmental Durability: The IS200JGPAG1A’s IPC-CC-830 Class 3 conformal coating provides superior resistance to salt spray, chemical vapors, and condensation—common in coastal power plants or offshore rigs. Unlike standard-coated modules (which degrade in 3–5 years in harsh environments), the IS200JGPAG1A maintains performance for 12+ years. In a Gulf Coast oil refinery, this coating has proven to withstand hurricane-related moisture ingress, while its -10 °C to 65 °C operating range ensures reliability in both arctic LNG facilities and desert power plants.

Typical Application Scenarios

In power generation, the IS200JGPAG1A is a staple in GE Mark VIe-equipped combined-cycle gas turbine (CCGT) plants. It integrates with the turbine’s fuel control system, powering 3-phase AC fuel injectors (via AC channels) and 24V DC fuel pressure sensors (via DC channels). The IS200JGPAG1A’s redundant input ensures these components stay powered during grid transients, preventing fuel flow disruptions that could trigger costly turbine shutdowns. Plant operators also use the module’s digital status signals to track actuator power consumption, identifying wear before failures occur—reducing unplanned downtime by 35% annually.

In oil & gas, the IS200JGPAG1A supports steam turbines in pipeline compression stations. Here, it supplies AC power to electric valve actuators (regulating natural gas flow) and DC power to corrosion-resistant pressure transmitters. The IS200JGPAG1A’s enhanced coating protects against pipeline gases and dust, while its adjustable fuses prevent overcurrent damage to expensive flow sensors. During routine maintenance, technicians can reconfigure channels without rewiring—for instance, repurposing a DC channel to power a new vibration monitor—saving 8+ hours of setup time compared to fixed-configuration modules.

In marine propulsion, the IS200JGPAG1A is integrated into GE Mark VI-controlled shipboard gas turbines. It powers AC propulsion actuators and DC navigation sensors, with its dual-input redundancy critical for avoiding propulsion loss at sea. The module’s compact size fits within tight engine room spaces, and its digital diagnostics feed into the ship’s bridge HMI—letting captains monitor power status without accessing the engine room. For naval vessels, this means faster response to power anomalies, ensuring mission continuity in remote waters.

Related Model Recommendations

IS200JPDBH1A: GE’s AC power supply board, the primary input source for the IS200JGPAG1A’s AC channels—supplies stabilized 120V AC via 5A fused circuits. Mandatory for AC load operation.

IS200JDCBH1A: GE’s DC redundant supply board, paired with the IS200JGPAG1A to provide 24V DC backup power—enables the module’s failover functionality.

IS200PPDAH1A: GE’s PPDA connector card, required for physical/electrical integration between the IS200JGPAG1A, JPDB, and JDCB boards in Mark VI chassis.

IS200JGPAG2A: Upgraded version of the IS200JGPAG1A with 8 channels (4 AC + 4 DC) and Ethernet-based remote configuration—ideal for large-scale multi-turbine systems.

IS200TBAIH1A: GE’s terminal block assembly, designed to organize the IS200JGPAG1A’s load wiring—reduces installation time and simplifies future reconfiguration.

IS200PCCAG1A: GE’s power conditioning card, used with the IS200JGPAG1A in unstable grids (e.g., remote mines) to filter voltage spikes and ensure clean power delivery.

IS200MDDHG1A: GE’s Mark VI I/O module, a common load powered by the IS200JGPAG1A—processes sensor data and sends commands to actuators, creating a closed-loop control system.

IS200JGPAG1B: Revision of the IS200JGPAG1A with extended temperature range (-20 °C to 70 °C) for extreme-environment applications (e.g., arctic pipelines, desert solar farms).

IS200JGPAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200JGPAG1A, confirm compatibility with GE Mark VI/VIe chassis and verify availability of JPDB and JDCB boards. Power off the entire Mark VI system and lock out/tag out AC/DC supplies to prevent electrical hazards. Use an anti-static wristband and ESD mat when handling the IS200JGPAG1A to protect its microelectronics. Required tools: Phillips #2 screwdriver, torque wrench (0.4–0.6 N·m), wire strippers (12–22 AWG), and a multimeter. Align the IS200JGPAG1A with the chassis guide rails, secure with front-panel screws, then connect the PPDA connector to the backplane. Terminate load wires to the module’s terminal blocks (AC: red/black; DC: positive/negative) and verify polarities before powering on.

Maintenance suggestions: Perform monthly inspections of the IS200JGPAG1A: check bi-color LEDs (no red faults), tighten terminal blocks (torque to 0.5 N·m), and remove dust with a dry brush. Every 6 months, use a multimeter to test fuse continuity and verify input voltages (AC: 110–130V; DC: 22–26V). If a channel’s LED turns red, isolate the load first, then replace the fuse with a GE-approved unit of the same rating—never use higher-amperage fuses. Annual maintenance includes updating the Mark VI controller’s status monitoring firmware to ensure compatibility with the IS200JGPAG1A’s digital signals. For persistent faults (e.g., frequent failovers), contact GE service to inspect the module’s internal power management circuitry.

Service and Guarantee Commitment

The IS200JGPAG1A comes with GE’s industry-leading 3-year manufacturer’s warranty, covering material defects and workmanship—extending 1 year beyond standard power modules. GE guarantees the IS200JGPAG1A will operate in compliance with Mark VI/VIe system specifications, with free repair or expedited replacement (24-hour shipping for critical applications) if performance standards are not met.

Customers gain access to GE’s global technical support network for the IS200JGPAG1A, including 24/7 phone/email assistance, online training modules, and downloadable configuration guides. For large-scale projects (e.g., CCGT plant upgrades), GE provides on-site commissioning services to ensure the IS200JGPAG1A is calibrated to specific turbine loads and integrated with existing control logic. Extended service plans (up to 7 years) are available, including annual preventive maintenance and priority access to GE’s turbine control experts—reflecting GE’s confidence in the IS200JGPAG1A’s reliability and commitment to maximizing customer uptime.