Description

GE IS200ISBBG2AAB Product Description

Product Overview

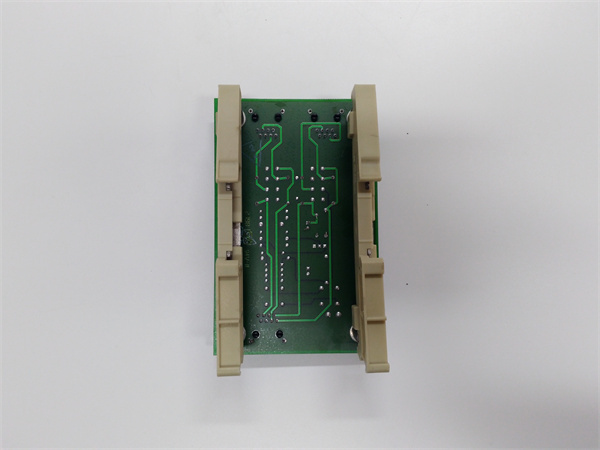

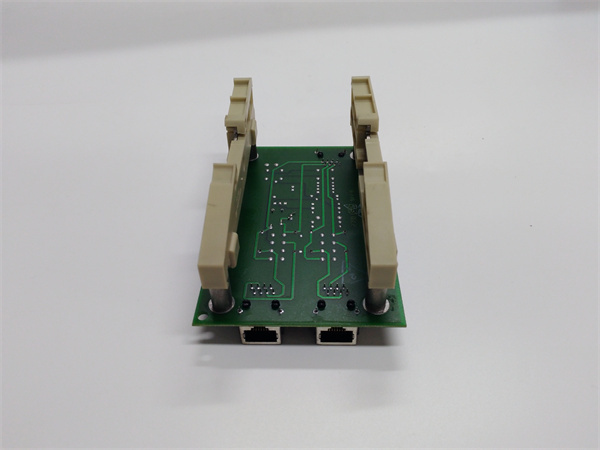

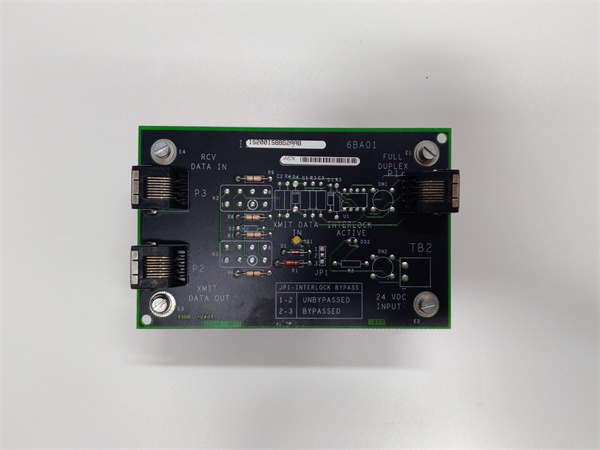

The GE IS200ISBBG2AAB is a high-reliability InSync Bus Bypass Card engineered for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), specializing in turbine excitation control applications. As a critical component of the EX2100 series, GE IS200ISBBG2AAB ensures seamless redundancy and fault tolerance by bypassing compromised communication buses, maintaining uninterrupted data flow between control modules in gas, steam, and combined-cycle turbine systems. This capability is vital for preventing shutdowns during transient faults, such as bus signal loss or EMI interference, thereby enhancing operational continuity in power plants, oil refineries, and industrial facilities.

Designed with advanced insync technology, GE IS200ISBBG2AAB detects anomalies in the control bus network and activates a redundant bypass path within milliseconds, minimizing latency and ensuring real-time control integrity. Its rugged construction includes a conformal coating to protect against moisture, dust, and corrosion, making it suitable for harsh environments with temperature extremes (-40°C to +70°C) and high vibration. By integrating with GE’s Mark VI/VIe backplane, GE IS200ISBBG2AAB streamlines system architecture, reducing the need for external bypass relays and simplifying maintenance. Whether deployed in a 500MW utility turbine or a 150MW industrial compressor, this module ensures reliable turbine excitation control, optimizing efficiency and extending equipment lifespan.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200ISBBG2AAB |

| Manufacturer | General Electric (GE) |

| Product Type | InSync Bus Bypass Card (Mark VI/VIe DCS) |

| Bus Compatibility | GE COREBUS, Profibus DP (configurable) |

| Redundancy Mechanism | Automatic bypass switching (≤5ms response time) |

| Power Input | 24V DC (18–30V DC operating range) |

| Isolation Rating | 2500Vrms (bus-to-ground) |

| Operating Temperature | -40°C to +70°C |

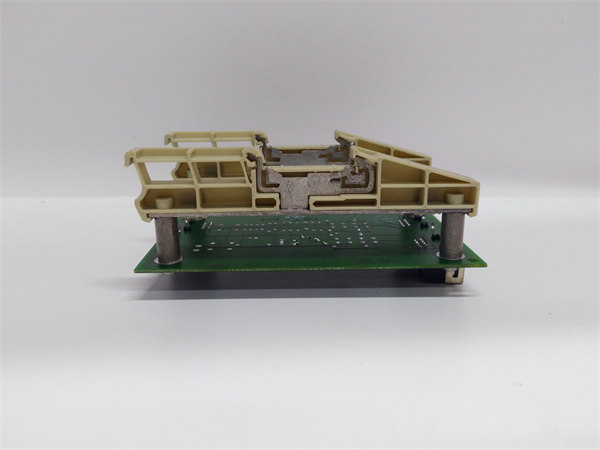

| Mounting Type | 19-inch rack-mount (1U height) |

| Physical Dimensions | 110mm (W) × 60mm (H) × 67mm (D) |

| Weight | 0.14kg |

| Coating | Normal conformal coating (IP54 equivalent) |

| Compliance | UL, CE, ISO 9001:2015 |

| Diagnostic Features | LED indicators (green = normal, red = fault); self-test via Mark VI HMI |

IS200ISBBG2AAB

Main Features and Advantages

Real-Time Bus Redundancy: GE IS200ISBBG2AAB continuously monitors the health of the control bus and instantaneously switches to a redundant path if a fault is detected, ensuring zero downtime for critical turbine excitation control loops. This is critical in applications where a single bus failure could trigger a costly shutdown, such as in offshore gas turbines or baseload power plants.

Rugged Environmental Resilience: The module’s conformal coating and EMI shielding protect against industrial contaminants (e.g., oil mist, salt spray) and electromagnetic interference from nearby generators or motors, maintaining signal integrity in harsh environments. Its wide operating temperature range (-40°C to +70°C) makes it suitable for extreme climates, such as arctic LNG facilities or desert power stations.

Simplified System Integration: By eliminating the need for external bypass relays, GE IS200ISBBG2AAB reduces control cabinet complexity and wiring by up to 30%. It directly integrates with GE’s Mark VI/VIe backplane, enabling plug-and-play installation and minimizing commissioning time.

Advanced Diagnostics: Built-in LED indicators and self-test functionality allow technicians to quickly identify faults (e.g., bus communication loss) via the Mark VI HMI, reducing troubleshooting time by 40%. This proactive monitoring helps prevent cascading failures and supports predictive maintenance strategies.

Application Field

GE IS200ISBBG2AAB is primarily deployed in industries where uninterrupted turbine control is mission-critical, with key applications in:

Power Generation: In combined-cycle power plants, GE IS200ISBBG2AAB ensures seamless redundancy for excitation control systems, protecting against bus faults during load transitions or grid disturbances. A 450MW gas-fired plant in the Middle East reported a 70% reduction in unplanned outages after implementing GE IS200ISBBG2AAB, saving $2.1M annually in lost generation revenue.

Oil & Gas: Offshore platforms use GE IS200ISBBG2AAB to maintain communication between turbine control modules and compressor anti-surge systems, even during storm-induced EMI. A North Sea platform avoided a $1.2M shutdown by leveraging the module’s rapid bypass switching during a lightning strike.

Industrial Manufacturing: In petrochemical facilities, GE IS200ISBBG2AAB safeguards turbine-driven pumps and compressors, ensuring continuous operation of critical processes like ethylene cracking. A Gulf Coast refinery reduced maintenance hours by 25% by using the module’s diagnostic features to pre-empt bus-related issues.

Related Products

GE IS200TCCAG1B: Communication interface module that pairs with GE IS200ISBBG2AAB to enable Modbus TCP/IP connectivity with third-party DCS systems (e.g., Emerson DeltaV).

GE IS200TPSAG1A: Redundant power supply that provides stable 24V DC to GE IS200ISBBG2AAB, ensuring uninterrupted operation during voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures bus status data from GE IS200ISBBG2AAB for trend analysis and fault prediction.

GE IS200TCAAH1ABA: Thermocouple interface module that works alongside GE IS200ISBBG2AAB to process temperature signals in turbine bearing monitoring systems.

GE IC660HHM501: Handheld monitor used to verify bus communication status and configure GE IS200ISBBG2AAB parameters on-site.

IS200ISBBG2AAB

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200ISBBG2AAB, verify compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and ensure the 19-inch rack has 1U of available space. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s sensitive components. Label all bus cables to match GE IS200ISBBG2AAB’s port markings (e.g., “MAIN BUS IN,” “REDUNDANT BUS OUT”) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200ISBBG2AAB to check for loose connectors, corrosion, or illuminated fault LEDs. Use compressed air (30 PSI max) to clean dust from the module and rack. Quarterly, update firmware using GE’s Proficy Machine Edition software to ensure compatibility with the latest Mark VI/VIe protocols. If a fault is detected (red LED), power down the associated I/O rack before replacing GE IS200ISBBG2AAB—always use a factory-calibrated unit to maintain system integrity.

Product Guarantee

GE guarantees the reliability and performance of GE IS200ISBBG2AAB with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in turbine control systems and can assist with configuration, troubleshooting, and firmware updates. For mission-critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200ISBBG2AAB’s bypass functionality and system integration. Additionally, GE provides repair services for GE IS200ISBBG2AAB, including full functional testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.