Description

Key Technical Specifications

-

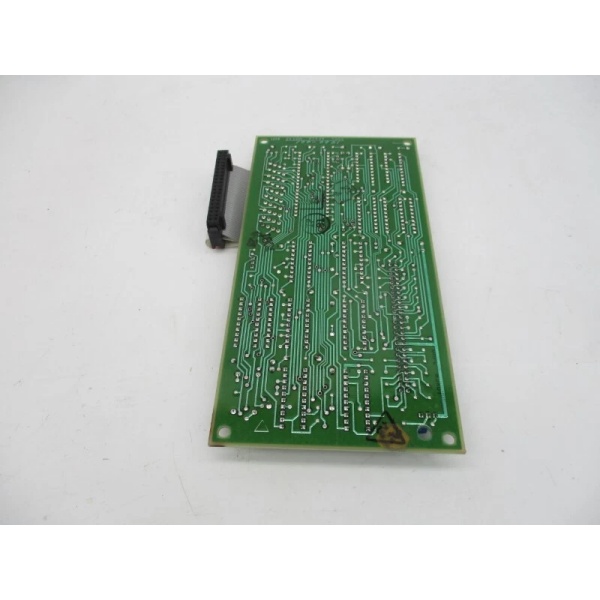

Model Number: IS200ICBDH1ACB

-

Manufacturer: General Electric

-

Logic Voltage: +5 V @ 1 A, ±12 V @ 150 mA from VME back-plane

-

Analog Inputs: 12 differential, ±10 V or 4-20 mA jumper-select, 12-bit resolution, 5 kHz BW

-

Analog Outputs: 4 isolated, ±10 V, 5 mA drive, short-circuit protected

-

Signal Types: LVDT, servo current, 4-20 mA fuel/pressure, TC mV, vibration (Velomitor/Accel), gen/line volts

-

Connectors: 96-pin DIN VME, two 20-position pluggable (JE, 3PL) for field cables

-

Isolation: 1500 Vrms channel-to-logic, 500 V channel-to-channel

-

Diagnostics: Green “BOARD OK,” red “FAULT” LEDs visible through bezel

-

Operating Temperature: –20 °C to +70 °C (conformal-coated)

-

Dimensions / Weight: 22 × 16 × 9 cm, 2.3 kg

GE DS3800DMPC1F1E

Field Application & Problem Solved

A 2000-frame-7 peaker still expects clean, isolated ±10 V signals that represent servo current, LVDT position, fuel pressure, and exhaust temperature. The IS200ICBDH1ACB is the card that does the scaling. It sits in the Mark VI VME rack, reads raw mV from thermocouples, 4-20 mA from fuel-flow transmitters, and ±10 V from dual LVDTs, then dumps the data onto the VME bus every 10 ms. When the card drifts—usually a precision divider resistor opens—you see 3 % low servo current and the unit trips on “SERVO FAULT DIFF”; swap the board, re-torque the JE and 3PL plugs, and the numbers snap back to the original calibration. You’ll find this PCB in any Mark VI that still uses the RST I/O scheme: paper-mill back-pressure sets, refineries, and every frame-7 that never upgraded to Mark VIe. Its value is repeatability: the divider network is laser-trimmed, so you get the same servo gain the turbine was commissioned with—critical for keeping old electromechanical overspeed bolts happy.

A 2000-frame-7 peaker still expects clean, isolated ±10 V signals that represent servo current, LVDT position, fuel pressure, and exhaust temperature. The IS200ICBDH1ACB is the card that does the scaling. It sits in the Mark VI VME rack, reads raw mV from thermocouples, 4-20 mA from fuel-flow transmitters, and ±10 V from dual LVDTs, then dumps the data onto the VME bus every 10 ms. When the card drifts—usually a precision divider resistor opens—you see 3 % low servo current and the unit trips on “SERVO FAULT DIFF”; swap the board, re-torque the JE and 3PL plugs, and the numbers snap back to the original calibration. You’ll find this PCB in any Mark VI that still uses the RST I/O scheme: paper-mill back-pressure sets, refineries, and every frame-7 that never upgraded to Mark VIe. Its value is repeatability: the divider network is laser-trimmed, so you get the same servo gain the turbine was commissioned with—critical for keeping old electromechanical overspeed bolts happy.

Installation & Maintenance Pitfalls (Expert Tips)

LVDT common-mode blow-up—differential only, never ground

The LVDT inputs are true differential; land the shield on the wrong pin and you stuff 120 VAC into a 10 V amplifier—op-amp blows, card smells like fish. Always tie shield drain at the junction box only, float it at the card.

The LVDT inputs are true differential; land the shield on the wrong pin and you stuff 120 VAC into a 10 V amplifier—op-amp blows, card smells like fish. Always tie shield drain at the junction box only, float it at the card.

JE vs 3PL reversal—+24 V on mV input cooks the amp

The JE and 3PL headers are keyed alike but pin-outs differ. Land the servo cable on the thermocouple header and you stuff +24 V into a 100 mV input—trace burns open. Match the white wire-stripe to the silk-screen arrow before you push the plug home.

The JE and 3PL headers are keyed alike but pin-outs differ. Land the servo cable on the thermocouple header and you stuff +24 V into a 100 mV input—trace burns open. Match the white wire-stripe to the silk-screen arrow before you push the plug home.

Conformal coat cracked—salt fog kills the 2.5 V reference

The board is coated, but the 20-pin edge is masked. If the coat cracks, salt bridges the precision reference and you see 5 % offset on every channel. Scrape the salt, hit the edge with 2100-FTG, and re-coat—problem gone for another decade.

The board is coated, but the 20-pin edge is masked. If the coat cracks, salt bridges the precision reference and you see 5 % offset on every channel. Scrape the salt, hit the edge with 2100-FTG, and re-coat—problem gone for another decade.

Missing shoulder washers—card arcs to rack

The four corner holes are through-plated. Forget the fiber washers and the card edge sits 0.5 mm proud; 125 V generator voltage finds the rack paint, arcs, and blows a hole in the ground plane. Use the original GE shoulder washers—torque to 8 in-lb, no more.

The four corner holes are through-plated. Forget the fiber washers and the card edge sits 0.5 mm proud; 125 V generator voltage finds the rack paint, arcs, and blows a hole in the ground plane. Use the original GE shoulder washers—torque to 8 in-lb, no more.

GE DS3800DMPC1F1E

Technical Deep Dive & Overview

IS200ICBDH1ACB is a 12-channel analog front-end frozen in 2000 silicon. A quad 741 op-amp array scales LVDT and servo signals; a 12-bit ADC converts them; an FPGA latches the data onto the VME bus every 10 ms. Because everything is hardware-scaled, you can swap the card hot and the controller never knows—just kill the 24 VDC field power first or you’ll arc-weld the 20-pin plugs. Think of it as a ruggedized signal conditioner that lives in a coal-dust cabinet; treat the differential inputs like instrumentation jewels and the servo loop will stay rock-solid for another thirty years

IS200ICBDH1ACB is a 12-channel analog front-end frozen in 2000 silicon. A quad 741 op-amp array scales LVDT and servo signals; a 12-bit ADC converts them; an FPGA latches the data onto the VME bus every 10 ms. Because everything is hardware-scaled, you can swap the card hot and the controller never knows—just kill the 24 VDC field power first or you’ll arc-weld the 20-pin plugs. Think of it as a ruggedized signal conditioner that lives in a coal-dust cabinet; treat the differential inputs like instrumentation jewels and the servo loop will stay rock-solid for another thirty years

.