Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200ESELH1A |

| Manufacturer | General Electric (GE) |

| Product category | Enhanced Signal Selection & Logic Handling Module (Mark VI Speedtronic Turbine Control Series) |

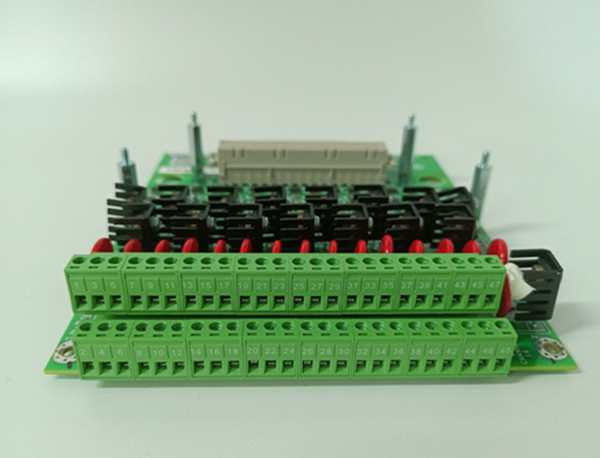

| Signal selection channels | 8 dual-input selection channels (16 total inputs, 8 outputs; software-configurable source priority) |

| Supported signal types | Analog: ±5 V DC, ±10 V DC, 0–20 mA, 4–20 mA; Digital: TTL (5 V), dry contact (0–30 V DC) |

| Logic processing capabilities | Programmable Boolean logic (AND/OR/NOT), signal validation (range checks), fault voting (1oo2/2oo3) |

| Isolation voltage | 1500 Vrms (input-to-output); 500 Vrms (channel-to-channel); 1000 Vrms (channel-to-ground) |

| Switching latency | <10 µs (analog); <5 µs (digital) |

| Input protection | Overvoltage (±30 V clamp), overcurrent (25 mA limit), ESD (±15 kV air discharge), surge protection (IEC 61000-4-5) |

| Power requirement | 24 V DC (dual redundant inputs, 22–26 V DC); 5 V DC (internal logic, derived from 24 V input) |

| Operating temperature range | -20 °C to 70 °C (-4 °F to 158 °F) |

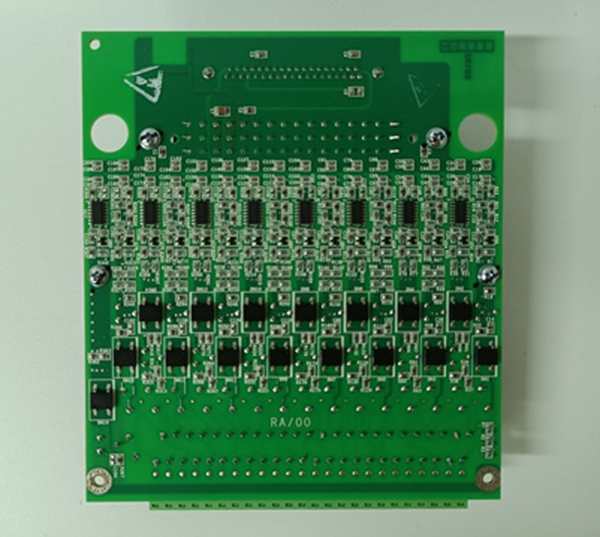

| Physical dimensions | 177.8 mm × 203.2 mm × 30.5 mm (7 in × 8 in × 1.2 in) [GE Mark VI chassis standard] |

| Weight | 375 g (13.2 oz) |

| Coating | IPC-CC-830 Class 3 enhanced conformal coating (resists salt spray, moisture, industrial chemicals) |

| Interface type | GE Mark VI Backplane Connector (for logic sync); terminal blocks (signal I/O); LED status indicators (per channel) |

| Compliance standards | UL 508, IEC 61010-1, IEC 61326-1 (EMC), RoHS 3, CE |

IS200ESELH1A

Product Introduction

The IS200ESELH1A is an enhanced signal selection & logic handling module engineered by General Electric (GE), exclusively designed for GE’s Mark VI Speedtronic turbine control systems—critical infrastructure for power generation, oil & gas, and safety-critical industrial turbine operations. As a specialized member of GE’s IS200-series, the IS200ESELH1A solves a pivotal challenge in turbine control: dynamically selecting redundant sensor signals (e.g., dual pressure transmitters) and processing safety logic to ensure reliable, fault-tolerant operation—even when primary signals fail.

Unlike basic signal switches, the IS200ESELH1A integrates both signal selection and programmable logic, eliminating the need for separate switching and logic modules. It locks to the Mark VI controller’s backplane clock for synchronized signal switching, while its dual redundant power inputs (paired with GE’s IS200JGPAG1A power module) ensure uninterrupted operation during power transients. For plants prioritizing safety and uptime—such as nuclear power auxiliaries or offshore gas turbines—the IS200ESELH1A’s fault-voting capabilities and fast switching latency make it indispensable for maintaining control loop integrity.

Core Advantages and Technical Highlights

Redundant Signal Selection for Fault Tolerance: The IS200ESELH1A’s 8 dual-input channels enable automatic or manual selection of redundant sensor signals, a critical feature for safety-critical turbine loops. In a nuclear power plant’s steam turbine system, for example, the module monitors two redundant 4–20 mA pressure transmitters (primary and backup) for the reactor feedwater line. If the primary signal exceeds a predefined error range (e.g., out-of-calibration), the IS200ESELH1A switches to the backup signal in <10 µs—fast enough to avoid control loop instability. This redundancy replaces manual signal switching, reducing human error and preventing unplanned downtime caused by single-sensor failures.

Programmable Safety Logic for Compliance: The IS200ESELH1A’s built-in Boolean logic and fault-voting capabilities (1oo2/2oo3) simplify compliance with industrial safety standards (e.g., IEC 61508). A gas turbine plant, for instance, uses the module’s 2oo3 (two-out-of-three) voting logic to validate three independent vibration sensor signals: the IS200ESELH1A only triggers an alarm if two or more sensors detect abnormal vibration, preventing nuisance shutdowns from single-sensor noise. This logic processing eliminates the need for a separate PLC, cutting chassis space usage by 30% and reducing system complexity—key for retrofitting legacy Mark VI systems with modern safety features.

Fast Switching Latency for Control Loop Stability: With <10 µs analog switching latency and <5 µs digital latency, the IS200ESELH1A ensures control loops remain stable during signal transitions. In a combined-cycle gas turbine (CCGT) plant, the module switches between two fuel pressure sensor signals during routine sensor calibration—its low latency ensures the Mark VI controller doesn’t experience pressure signal gaps, which could cause fuel flow oscillations and 1–2% efficiency losses. This performance exceeds slow mechanical switches (100+ µs latency) and generic electronic switches (50+ µs latency), making it ideal for fast-response control loops.

Industrial-Grade Isolation and Durability: The IS200ESELH1A’s 1500 Vrms input-to-output isolation protects the Mark VI controller from cross-channel interference and high-voltage transients (e.g., 10 kV generator EMI). In a coastal power plant, its IPC-CC-830 Class 3 coating resists salt spray and humidity, while its -20 °C to 70 °C operating range handles seasonal temperature swings. GE’s accelerated life testing confirms the module operates reliably for 15+ years in these conditions—matching the lifespan of critical turbine components—reducing long-term replacement costs and maintenance frequency.

Typical Application Scenarios

In power generation, the IS200ESELH1A is a staple in GE Mark VI-equipped nuclear power plant auxiliary turbines. It manages redundant signal selection for 8 critical loops: 4 feedwater pressure loops (dual 4–20 mA transmitters each) and 4 condenser vacuum loops (dual ±10 V sensors each). The IS200ESELH1A uses 1oo2 (one-out-of-two) logic to switch to backup signals if primary sensors fail, ensuring continuous feedwater flow and condenser efficiency. Its fast switching latency prevents control loop instability during transitions, while its fault-voting logic complies with NRC 10 CFR Part 50 safety requirements. For plant operators, this means enhanced safety compliance and zero unplanned downtime from sensor failures.

In oil & gas, the IS200ESELH1A supports offshore gas turbines in drilling platforms. It processes signals from dual thermocouples (Type K) monitoring turbine exhaust temperature and dual dry-contact pressure switches (high/low) for fuel gas lines. The module’s Boolean logic combines the pressure switch signals (AND logic: only allow fuel flow if pressure is within range) and selects the more reliable thermocouple signal (via range checks). Its conformal coating resists salt spray, while its redundant power inputs (powered by the platform’s backup DC system) ensure operation during primary power outages—critical for maintaining drilling operations in remote offshore locations.

In industrial manufacturing, the IS200ESELH1A integrates with Mark VI-controlled steam turbines for chemical process heating. It selects between dual RTD (Pt100) signals for reactor temperature monitoring and switches between two 0–10 V control signals for steam valve actuators during maintenance. The module’s logic processing ensures the steam valve remains in a safe position if both RTD signals fail, preventing overheating and batch rejects. Its low switching latency also ensures temperature control remains precise (±0.5 °C) during signal transitions, critical for producing high-purity chemicals that require tight process tolerances.

Related Model Recommendations

IS200JGPAG1A: GE’s dual-mode power module, supplies redundant 24 V DC power to the IS200ESELH1A—ensuring uninterrupted signal selection during power transients.

IS200EXAMG1A: GE’s analog monitoring & alarm module, pairs with the IS200ESELH1A to add alarm functionality for selected signals (e.g., high temperature alerts).

IS200MDDHG1A: GE’s analog I/O module, expands the IS200ESELH1A’s capabilities by handling additional non-redundant signals (e.g., ambient temperature) in Mark VI systems.

IS200TBAIH1A: GE’s terminal block assembly, organizes the IS200ESELH1A’s 16 input/8 output wires—reducing wiring errors and simplifying maintenance.

IS200PPDAH1A: GE’s backplane adapter, resolves compatibility issues between the IS200ESELH1A and older Mark VI chassis revisions (pre-revision 3.0).

IS200PCCAG1A: GE’s power conditioning card, filters voltage noise for the IS200ESELH1A in unstable grids (e.g., remote mining turbines)—preventing logic errors from power fluctuations.

IS200JDCBH1A: GE’s DC redundant supply board, adds a third backup 24 V DC input to the IS200ESELH1A—maximizing uptime in mission-critical applications like nuclear power.

IS200ESELH2A: Upgraded version of the IS200ESELH1A with 12 dual-input channels (24 total inputs) and Ethernet remote configuration—ideal for large-scale turbine systems (e.g., CCGT complexes).

IS200ESELH1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200ESELH1A, confirm compatibility with your GE Mark VI chassis (revision ≥3.0) and verify the controller firmware is v4.5+ (for logic sync support). Power off the turbine control system and lock out/tag out all AC/DC supplies to avoid electrical shock. Use an anti-static wristband and ESD mat when handling the IS200ESELH1A—its logic circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.3–0.5 N·m), wire strippers (18–24 AWG), signal generator, and oscilloscope. Align the module with the Mark VI chassis guide rails, secure with front-panel screws, then connect the backplane connector (critical for logic synchronization). Terminate redundant signal wires to the terminal blocks (label primary/backup clearly) and test isolation resistance (≥150 MΩ) with a megohmmeter before powering on.

Maintenance suggestions: Perform monthly inspections of the IS200ESELH1A: check LED status (green = normal, amber = signal switch, red = fault), tighten terminal blocks (retorque to 0.4 N·m), and remove dust with a dry, lint-free cloth. Every 6 months, use a signal generator to test switching latency (ensure <10 µs for analog) and validate logic rules (e.g., 2oo3 voting). Simulate a primary signal failure to confirm the module switches to backup within specifications. Annual maintenance includes updating the module’s firmware via the Mark VI controller and inspecting the conformal coating for cracks (repair with GE-approved coating if damaged). For persistent logic errors, contact GE service to recalibrate the module’s internal logic processor—do not modify hardware, as this voids the warranty.

Service and Guarantee Commitment

The IS200ESELH1A comes with GE’s industry-leading 3-year manufacturer’s warranty, covering defects in materials, workmanship, switching latency, and logic processing performance. GE guarantees the IS200ESELH1A will maintain its published specifications for the warranty period, with free expedited replacement (24-hour shipping for critical power/oil & gas applications) if it fails to meet operational requirements.

Customers gain access to GE’s Legacy Turbine Support Network for the IS200ESELH1A, including 24/7 phone/email assistance from Mark VI logic experts, online logic programming tutorials, and archived technical documentation for legacy systems. For large-scale retrofits (e.g., upgrading safety loops in nuclear auxiliaries), GE provides on-site commissioning to ensure the IS200ESELH1A’s logic aligns with safety standards and integrates seamlessly with existing Mark VI infrastructure. Extended service plans (up to 8 years) include annual logic validation, priority access to replacement parts for legacy systems, and remote troubleshooting—reflecting GE’s commitment to safety-critical turbine operations and maximizing the IS200ESELH1A’s long-term value.