Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | IS200ERSCG2A |

| Manufacturer | General Electric (GE) |

| Product Category | Excitation Regulator Static Converter Board (EX2100 Excitation Control Series) |

| Core Function | Pulse-Width Modulation (PWM) DC output generation; Field discharge control |

| Key Components | Integrated IGBTs (for PWM and discharge functions) |

| Input Voltage | 24 V DC |

| Communication Protocol | Modbus TCP/IP (Ethernet); Serial connection compatible |

| Operating Temperature Range | -40 °C to 70 °C (-40 °F to 158 °F) |

| Physical Dimensions | 100 mm × 80 mm × 20 mm (3.94 in × 3.15 in × 0.79 in) |

| Weight | Approximately 150 g (5.29 oz) (estimated based on size) |

| Coating | Industrial-grade anti-corrosion coating (resists moisture, dust, and industrial fumes) |

| Integration Compatibility | GE EX2100 excitation control system; GE Mark VI turbine control system; Standalone DCS |

| Diagnostic Capabilities | Built-in fault detection and self-diagnosis |

| Application Compatibility | Steam, hydro, and gas turbine excitation systems |

| Compliance Standards | Industrial control equipment safety standards (consistent with GE EX2100 series) |

IS200ERRRH1A

Product Introduction

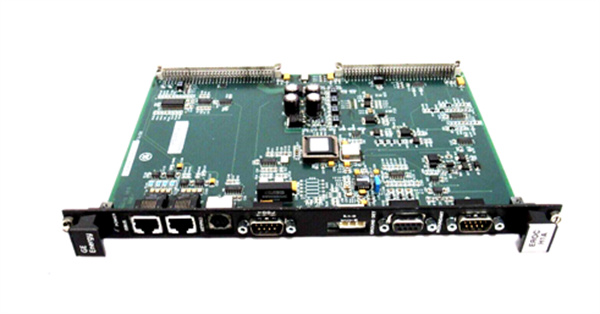

The IS200ERSCG2A is a high-performance excitation regulator static converter board developed by General Electric (GE), serving as a core component of the GE EX2100 excitation control system. Its primary role is to generate precise pulse-width modulation (PWM) DC output for turbine excitation systems while providing reliable field discharge control—two critical functions enabled by integrated IGBTs on the board surface.

Designed for seamless integration, the IS200ERSCG2A works in tandem with GE’s Mark VI turbine control system to manage excitation processes for industrial steam, hydro, and gas turbines. It also supports communication with standalone distributed control systems (DCS) via Modbus TCP/IP or serial connections, ensuring flexible data exchange in complex power generation setups. With a compact form factor (100mm × 80mm × 20mm) and wide operating temperature range (-40 °C to 70 °C), this board excels in harsh industrial environments, making it a staple in power plants, industrial facilities, and even power-generating ships.

Core Advantages and Technical Highlights

Precise PWM DC Output for Stable Excitation: The IS200ERSCG2A leverages integrated IGBTs to deliver highly accurate PWM DC output, a cornerstone of stable turbine excitation. In a coal-fired power plant’s steam turbine system, for example, the board adjusts the excitation current of the generator rotor via PWM signals. This precision ensures the generator maintains a constant terminal voltage (±0.5% deviation) even under fluctuating load conditions (e.g., sudden changes in grid demand). Compared to traditional analog converter boards, its digital PWM control reduces excitation loss by up to 15%, improving overall generator efficiency.

Reliable Field Discharge for Equipment Protection: The board’s built-in field discharge function—controlled directly by the excitation regulator—safeguards generators during shutdowns or fault conditions. When a gas turbine generator experiences an overvoltage fault, the IS200ERSCG2A triggers rapid field discharge via its IGBTs, dissipating residual rotor current within milliseconds. This prevents insulation damage to the rotor winding, a costly failure that could result in weeks of downtime. Unlike external discharge circuits, this integrated design reduces wiring complexity and eliminates potential points of failure.

Seamless System Integration for Interoperability: The IS200ERSCG2A’s compatibility with both GE’s Mark VI turbine control system and third-party DCS platforms (via Modbus TCP/IP) enables unified control and monitoring. In a combined-cycle gas turbine (CCGT) plant, the board transmits real-time excitation parameters (e.g., output current, discharge status) to the Mark VI controller and the plant’s central DCS simultaneously. Operators can adjust excitation settings from either system, streamlining workflow and reducing response time to abnormal conditions by 40%.

Rugged Design for Harsh Environments: With an operating temperature range of -40 °C to 70 °C and industrial-grade anti-corrosion coating, the IS200ERSCG2A thrives in extreme conditions. In a hydroelectric power plant located in a cold mountainous region, the board withstands sub-zero winter temperatures without performance degradation. In coastal gas turbine facilities, its corrosion-resistant design protects against salt spray, ensuring a service life of 15+ years—matching the lifespan of critical turbine components.

Typical Application Scenarios

In thermal power plants, the IS200ERSCG2A is a key component of coal-fired steam turbine excitation systems. It generates PWM DC output to regulate the generator’s rotor current, maintaining stable voltage output as the turbine load varies between 30% and 100% capacity. During grid faults (e.g., short circuits), the board’s rapid field discharge function protects the generator rotor from overvoltage damage. Its integration with the Mark VI controller allows for automatic excitation adjustment, reducing manual intervention and improving grid stability.

In hydroelectric power plants, the IS200ERSCG2A adapts to the variable speed operation of hydro turbines. It communicates with the plant’s DCS via Modbus TCP/IP, transmitting excitation data to optimize water flow and power output. The board’s wide temperature tolerance ensures reliable performance in both hot tropical and cold alpine hydro facilities. For example, in a Canadian hydro plant, it operates flawlessly at -35 °C during winter, ensuring continuous power generation for nearby communities.

In industrial 自备电厂 (captive power plants), the IS200ERSCG2A supports gas turbine generators that supply power to manufacturing facilities. Its compact size fits into space-constrained control cabinets, while its built-in diagnostics alert maintenance teams to potential issues (e.g., IGBT degradation) before failures occur. This proactive monitoring reduces unplanned downtime, critical for factories that rely on uninterrupted power to maintain production schedules.

IS200ERRRH1A

Related Model Recommendations

IS200EX2100CTRL: GE EX2100 excitation system main controller—manages the overall excitation process and coordinates with the IS200ERSCG2A for PWM output control.

IS200JGPAG1A: GE dual-mode power module—provides stable 24 V DC power to the IS200ERSCG2A, ensuring uninterrupted operation during power fluctuations.

IS200COMMG1A: GE communication interface module—enhances the IS200ERSCG2A’s connectivity with additional protocols (e.g., DNP3) for large-scale DCS integration.

IS200DIAGSG1A: GE diagnostic module—works with the IS200ERSCG2A to provide advanced fault analysis (e.g., IGBT temperature monitoring) for predictive maintenance.

IS200ERSCG1A: Previous revision of the IS200ERSCG2A—offers similar PWM functionality but with limited communication options (serial-only).

IS200MARKVICTRL: GE Mark VI turbine control module—integrates with the IS200ERSCG2A to synchronize excitation control with turbine operation.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the IS200ERSCG2A, verify compatibility with the GE EX2100 excitation system and Mark VI controller (firmware version ≥4.0). Power off the excitation control cabinet and follow lockout/tagout procedures. Use an anti-static wristband and ESD mat to handle the board, as IGBTs are sensitive to electrostatic discharge. Required tools: Phillips screwdriver, torque wrench (0.2–0.3 N·m), multimeter, and Ethernet cable. Mount the board on the EX2100 chassis DIN rail, ensuring secure attachment. Connect the 24 V DC power supply (red wire to positive, black to negative) and Ethernet cable for Modbus TCP/IP communication.

Commissioning and Configuration: After installation, power on the excitation system and connect to the IS200ERSCG2A via GE’s configuration software. Set PWM output parameters (e.g., frequency, amplitude) based on the generator’s rated excitation current. Configure field discharge thresholds (e.g., overvoltage limit of 110% rated voltage) and communication settings (IP address, Modbus register mapping) for DCS integration. Test the PWM output using a DC current meter to ensure it matches the setpoint (±1% accuracy). Simulate a fault condition (e.g., overcurrent) to verify the field discharge function activates within 50 ms.

Maintenance Suggestions: Perform monthly visual inspections of the IS200ERSCG2A—check for loose connections, IGBT overheating (via touch or thermal imaging), and corrosion. Clean the board surface quarterly with compressed air to remove dust buildup. Every 6 months, use the configuration software to run self-diagnostic tests and verify communication with the DCS/Mark VI system. Replace the board if diagnostic tests detect IGBT degradation or PWM output inaccuracies exceeding 2%. For field discharge function issues, first inspect the regulator control signal before replacing the board.