Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

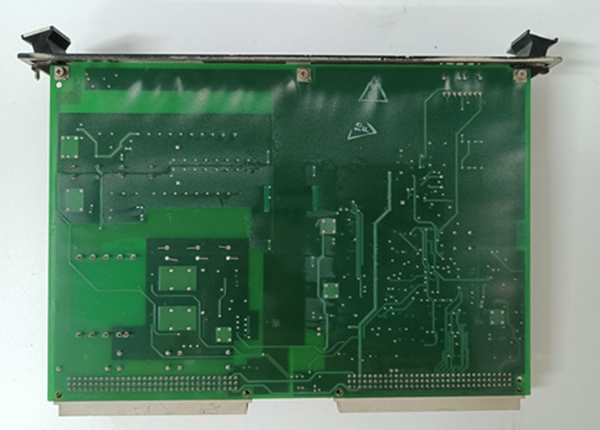

| Product Model | IS200EDEXG1A |

| Manufacturer | General Electric (GE) |

| Product Category | Excitation De-excitation Main Board (EX2100 Series) |

| Core Function | SCR de-excitation control, energy dissipation, conduction sensing |

| Power Supply | 24 VDC (from ESPM module) → 125 VDC conversion |

| Response Time | Millisecond-level (critical for emergency shutdowns) |

| Protection Features | Overvoltage, overcurrent protection; voltage retention (power failure) |

| Control Interface | Controlled by EXTB module; dual-trigger logic (control inputs/anode-cathode voltage) |

| Sensing Component | Hall effect conduction sensors (field current discharge monitoring) |

| Configuration | 6 configurable jumpers (JP1-JP6); Group 1 (for SCR de-excitation) |

| Operating Temperature | -20°C to +70°C (industrial-grade stability) |

| Shipping Weight | 3.5 lb |

| Compliance | Industrial-grade component standards (GE Energy Salem factory) |

| Repairability | Yes |

IS200EDEXG1A

Product Introduction

The IS200EDEXG1A is the core de-excitation module main board of GE’s EX2100 excitation control system, specifically engineered for SCR (silicon-controlled rectifier) de-excitation scenarios. As a critical safety component in generator systems, it bridges the excitation controller and power circuits, responsible for rapidly dissipating generator field energy during normal shutdowns or emergency aborts.

Unlike generic protection modules, this board integrates dual shutdown logic: normal shutdown (retard-limit firing for gradual field decay) and abort stop (immediate field contactor opening). It maintains voltage retention during power failures to ensure SCR firing capability, while Hall effect sensors provide real-time conduction feedback for closed-loop control. Its industrial-grade capacitors and voltage-limiting components ensure robustness against transient surges common in power generation environments.

Core Advantages and Technical Highlights

1. Ultra-Fast Emergency Response

Millisecond-level trigger speed enables rapid de-excitation (excitation current 降至零) in fault scenarios, preventing generator overspeed or grid instability. This meets the IEC 61508 safety integrity requirements for power system protection.

2. Redundant Control & Failsafe Design

Controlled by the EXTB module with fallback capability (EXTB initiates de-excitation if EDEX fails)

Voltage retention during power loss ensures critical shutdown sequences complete

Overvoltage/overcurrent protection shields thyristor bridges from damage

3. Flexible System Scalability

Supports master-slave configuration for multi-module deployment, adapting to large-capacity generator sets (e.g., 600MW+ fossil-fuel units). Configurable jumpers allow customization for specific SCR parameters.

4. Precision Sensing & Feedback

Hall effect sensors monitor field current discharge with high accuracy, while conduction sensing reports real-time status to the EX2100 controller. This enables predictive maintenance and fault diagnosis.

Typical Application Scenarios

1. Fossil-Fuel Power Plants

In coal/gas-fired power plants, the IS200EDEXG1A triggers de-excitation during grid faults (e.g., voltage collapse) or turbine trips. For example, during a generator stator short circuit, it dissipates field energy within 50ms to prevent winding damage.

2. Combined-Cycle Facilities

Coordinates with Mark VIe turbine controls during shutdown sequences: normal shutdowns use gradual de-excitation to avoid grid transients, while emergency aborts prioritize equipment protection.

3. Industrial Cogeneration

Protects on-site generators in chemical/paper plants from load surges. Its 125VDC operation aligns with industrial backup power systems for reliable performance.

4. Renewable Energy Hybrid Systems

Integrates with wind/solar hybrid generators to manage de-excitation during intermittent power inputs, ensuring grid compliance (e.g., IEEE 1547 anti-islanding requirements).

Related Model Recommendations

EXTB Module – Primary controller for IS200EDEXG1A; initiates de-excitation commands

IS200ECTBG2A – Thyristor gate driver; works with EDEX for SCR firing control

IS200EDCFG1A – Excitation configuration module; stores de-excitation parameter profiles

IS200EAUXH1A – Auxiliary I/O board; monitors field contactor status for EDEX

ESPM Module – Power supply source (24VDC) for EDEX’s 125VDC conversion

IS200IVFBG1A – Voltage feedback module; provides anode-cathode voltage triggers for EDEX

Installation, Commissioning and Maintenance

Installation Preparation

Power down EX2100 backplane before installation; use ESD protection gear

Verify 24VDC input from ESPM module (±10% tolerance)

Configure jumpers (JP1-JP6) per SCR specifications (refer to GEI-100466 manual)

Ensure hall effect sensors are calibrated for field current range

Commissioning

Use ToolboxST to link EDEX with EXTB module; test dual-trigger logic

Simulate normal/abort shutdowns to verify response time (<100ms target)

Validate conduction feedback signals against actual field current

Test power failure voltage retention (minimum 5s hold time)

Maintenance Suggestions

Monthly: Inspect capacitor integrity (no bulging/leakage); check jumper connections

Quarterly: Calibrate hall effect sensors; update firmware via GE Service Portal

On failure: Replace with Group 1 (SCR-compatible) revision; restore parameters from IS200EDCFG1A

IS200EDEXG1A

Service and Guarantee Commitment

GE provides a 2-year standard warranty for IS200EDEXG1A, covering manufacturing defects. Key support includes:

24/7 technical hotline for emergency de-excitation system troubleshooting

Access to GEH-6632 series manual and calibration tools

On-site service for critical power plants (response time <48 hours)

Extended warranty options with predictive maintenance (vibration/thermal monitoring)