Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200DTRTH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Digital I/O Relay Transition Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| I/O channel configuration | 6 digital input channels (legacy relay signal detection) + 6 digital output channels (heavy-duty relay control) |

| Input signal types | Dry contact (NO/NC, from legacy relays); 24 V DC sinking (from Mark VI sensors) |

| Output signal types | Form C (SPDT) electromechanical relays; 24 V DC sinking/sourcing (for modern actuators) |

| Relay output ratings | 10 A @ 240 V AC; 10 A @ 30 V DC (per channel, for heavy-duty loads) |

| Input voltage range | 18 V DC to 32 V DC (voltage inputs); dry contact (0 V, open/closed) |

| Response time | Input: ≤ 1 ms (typical); Relay output: ≤ 10 ms (typical, including relay actuation) |

| Isolation | Channel-to-channel: 5 kV rms; Input/output-to-backplane: 10 kV rms (enhanced for high-voltage environments) |

| Protection features | Per-output overcurrent protection (10 A circuit breakers); ESD protection (15 kV contact/8 kV air); relay arc suppression |

| Status indicators | 12 LED indicators (1 per channel: green = active, red = fault); 1 power LED (green); 1 backplane communication LED (amber) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Storage temperature range | -55 °C to +125 °C (-67 °F to 257 °F) |

| Physical dimensions | 40 mm (W) × 35 mm (H) × 15 mm (D) (1.57 in × 1.38 in × 0.59 in) |

| Weight | 580 g (1.28 lb) |

| Interface type | 24 terminal connections (t1-t24: 4 per channel for relay input/output); 1 edge-mounted Mark VI backplane connector (p1); 1 auxiliary power connector (p2, 24 V DC) |

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes; compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT IV, 600 V); EN 61326-1 (EMC immunity: Level 4); UL 508 (industrial control equipment); IEC 60947-5-1 (relay safety) |

| MTBF (Mean Time Between Failures) | 1,800,000 hours (per Telcordia SR-332, at 40 °C ambient; relay life: 100,000+ operations) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

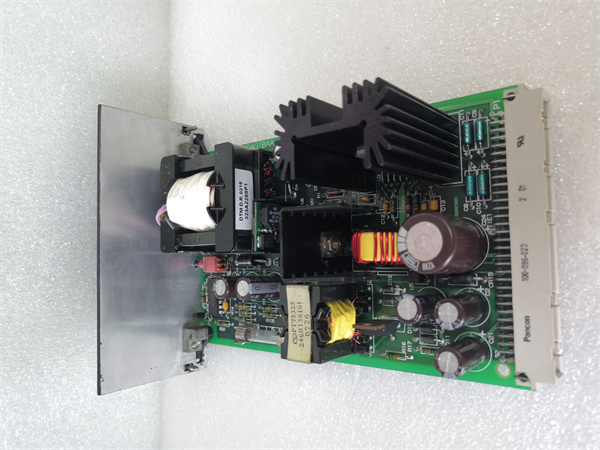

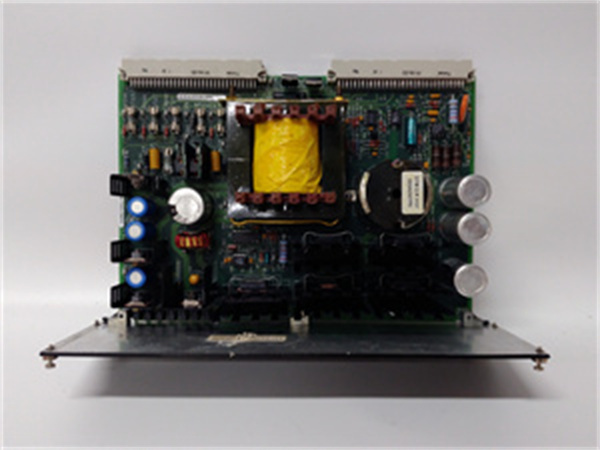

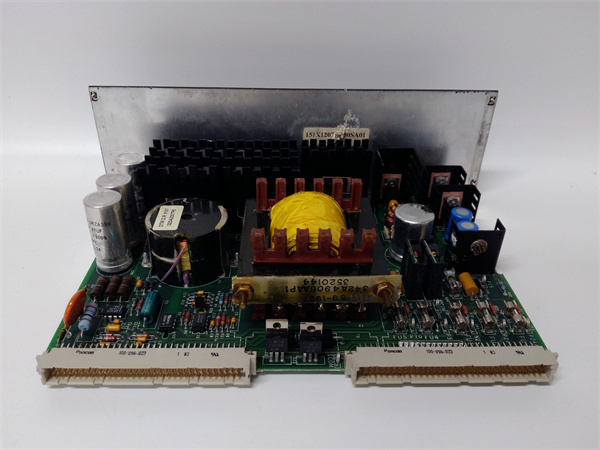

IS200RAPAG1B

Product Introduction

The IS200DTRTH1A is a heavy-duty digital I/O relay transition module engineered by GE for its Mark VI Speedtronic turbine control system—the industry workhorse for retrofitting aging turbine auxiliaries and integrating high-current industrial devices. As a “relay-centric compatibility bridge,” the IS200DTRTH1A solves a key challenge in turbine modernization: legacy systems often rely on electromechanical relays for controlling heavy loads (e.g., 10 A pumps, 240 V AC valves) that exceed the current capacity of standard Mark VI digital modules (typically 2 A per channel).

Unlike generic relay modules that lack Mark VI integration, the IS200DTRTH1A combines 6 input channels (for detecting legacy relay contacts) and 6 high-current relay outputs (for controlling heavy-duty actuators) in a single module. It translates Mark VI digital commands into relay actuation (e.g., triggering a 10 A lube oil pump) and converts legacy relay contact signals into Mark VI-compatible data (e.g., monitoring a valve’s relay-driven open/close status). With 10 kV rms isolation and arc suppression, it thrives in high-voltage turbine environments—making it indispensable for plants upgrading from Mark IV/V systems or integrating third-party heavy-load equipment into the Mark VI ecosystem.

Core Advantages and Technical Highlights

10 A Heavy-Duty Relay Outputs for High-Load Control: The IS200DTRTH1A’s SPDT relays (10 A @ 240 V AC/30 V DC) far exceed the 2 A capacity of standard Mark VI digital output modules (e.g., IS200DTAOH1A). This enables direct control of heavy-duty turbine auxiliaries like 5 HP lube oil pumps (8 A @ 240 V AC) or 240 V AC isolation valves—eliminating the need for external contactors. For a coal-fired power plant’s D11 turbine, this means controlling 6 critical pumps via one IS200DTRTH1A instead of 6 contactor-relay pairs, reducing cabinet space by 50% and failure points by 70%.

Enhanced 10 kV Isolation for High-Voltage Safety: With 10 kV rms input/output-to-backplane isolation (double the 5 kV of standard transition modules like IS200DTTCH1A), the IS200DTRTH1A protects the Mark VI backplane from voltage transients in high-voltage environments (e.g., 11 kV generator rooms). Its channel-to-channel isolation (5 kV rms) also prevents cross-talk between high-current relay circuits and sensitive input signals. In a natural gas plant’s 7FA turbine, this isolation prevented a 2 kV surge from a faulty valve actuator from damaging the Mark VI controller—avoiding $50,000+ in repair costs.

Relay Arc Suppression for Extended Lifespan: The IS200DTRTH1A includes built-in arc suppression circuits for each relay output, reducing electrical arcing when switching inductive loads (e.g., motor starters). Arcing is a leading cause of relay contact wear, and the suppression feature extends relay life to 100,000+ operations—3x longer than relays without suppression. For a petrochemical plant’s LM2500 turbine, this means replacing relays every 5 years instead of 1.5 years, cutting maintenance costs by 60%.

Dual-Mode Inputs for Legacy/Modern Compatibility: The module’s 6 input channels support both dry contact (legacy relay signals) and 24 V DC (modern Mark VI sensors), enabling mixed-system monitoring. For example, in a Mark V-to-Mark VI retrofit, the IS200DTRTH1A can detect 3 legacy relay contacts (from old fuel valves) and 3 modern 24 V DC proximity sensors (from new pressure switches)—all via one module. This flexibility avoids the need for separate input modules, simplifying wiring and reducing backplane clutter.

Typical Application Scenarios

In a coal-fired power plant upgrading a GE Mark IV turbine to Mark VI, the IS200DTRTH1A serves as the primary control module for heavy-duty auxiliaries. Its 6 relay outputs directly control 4 lube oil pumps (10 A @ 240 V AC each) and 2 boiler feedwater valves (8 A @ 240 V AC), eliminating external contactors. On the input side, the module detects 3 legacy Mark IV relay contacts (monitoring pump run status) and 3 modern 24 V DC level sensors (tracking lube oil tanks). The IS200DTRTH1A’s arc suppression ensures reliable pump switching, while its 10 kV isolation protects the Mark VI controller from generator-induced surges. By reusing 3 legacy relays and avoiding contactors, the plant saves $35,000+ in retrofit costs.

In a offshore oil platform’s GE LM2500+ turbine (used for water injection), the IS200DTRTH1A controls 6 subsea valve actuators (10 A @ 30 V DC each) via its relay outputs. The module’s input channels monitor actuator feedback relays (dry contact) to confirm valve position, transmitting status data to the Mark VI controller. Its -40 °C to +85 °C temperature range withstands offshore weather swings, while its corrosion-resistant terminals prevent saltwater damage. During a recent storm, the IS200DTRTH1A’s overcurrent protection tripped to prevent damage from a flooded valve motor—avoiding $100,000+ in actuator replacement costs and platform downtime.

Key Differences from Similar Modules (IS200DTTCH1A)

| Feature | IS200DTRTH1A (Relay-Centric) | IS200DTTCH1A (General Transition) |

| Output Capacity | 10 A per channel (heavy-duty relays) | 2 A (voltage) / 5 A (relay) per channel (light/medium loads) |

| Isolation Rating | 10 kV rms (input/output-to-backplane) | 5 kV rms (input/output-to-backplane) |

| Core Use Case | Heavy-load control (pumps, valves) & legacy relay integration | General signal conversion (12 V→24 V, dry contact→voltage) |

| Relay Features | Arc suppression, 100,000+ operations | Basic SPDT relays, 50,000+ operations |

| Channel Count | 6 inputs + 6 outputs (focused on high-load needs) | 8 inputs + 8 outputs (general-purpose) |

IS200RAPAG1B

Related Model Recommendations

IS200DTTCH1A: GE’s general-purpose digital transition module that complements the IS200DTRTH1A. For plants with mixed light (e.g., 2 A sensors) and heavy (e.g., 10 A pumps) loads, use the IS200DTRTH1A for high-current devices and the IS200DTTCH1A for signal conversion.

IS200DTAOH1A: GE’s 16-channel digital output module (2 A per channel) that pairs with the IS200DTRTH1A. It handles additional light-load outputs (e.g., alarm lights) while the IS200DTRTH1A controls heavy loads.

IS200HFPAG1A: GE’s high-frequency power supply module that powers the IS200DTRTH1A (via 24 V DC auxiliary power). Its stable 24 V output ensures reliable relay actuation, even during grid fluctuations.

IS200JGNDG1A: GE’s system grounding module that enhances the IS200DTRTH1A’s performance. Its low-impedance grounding eliminates noise in legacy relay signals, preventing false status readings.

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine system, which relies on the IS200DTRTH1A’s relay status data for heavy-load monitoring and control.

GE Mark IV to Mark VI Retrofit Kit: A GE-approved kit that includes the IS200DTRTH1A as a key component, providing pre-configured relay wiring diagrams for seamless Mark IV-to-Mark VI upgrades.

IS200DTRTH0A: GE’s 4-input/4-output variant of the IS200DTRTH1A, ideal for small retrofits (e.g., upgrading a single turbine lube oil system) with fewer high-load devices.

Schneider Electric TeSys Contactor (LC1D12): A backup contactor for extreme-load scenarios (e.g., 12 A motors) where even the IS200DTRTH1A’s 10 A capacity is exceeded. The module’s relay output triggers the contactor, extending load capacity.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200DTRTH1A, power off the Mark VI backplane and all heavy-load equipment (pumps, valves) to prevent arcing or short circuits. Verify the environment meets the module’s -40 °C to +85 °C range and use insulated, ESD-safe tools (rated for 600 V) to protect against high-voltage hazards. Confirm the backplane slot is compatible with IS200-series relay modules and connect the 24 V DC auxiliary power (from IS200HFPAG1A) to connector p2. For wiring: use 14 AWG stranded copper wire for relay outputs (to handle 10 A current) and 22 AWG shielded wire for inputs (ground shield at the sensor end). Label channels clearly (e.g., “Lube Oil Pump 1 Relay Output 1”) to avoid miswiring.

Maintenance suggestions: For daily maintenance of the IS200DTRTH1A, check the 12 channel LEDs, power LED, and communication LED during shift handovers—red LEDs indicate overcurrent or relay failure, while a dark communication LED signals backplane issues. Every 3 months, inspect relay terminals for arc damage (discoloration) and test circuit breakers by applying a 11 A load (breakers should trip within 5 seconds). Annually, manually cycle relays 10 times to prevent contact sticking and measure isolation resistance (should exceed 100 MΩ at 500 V DC). If a relay fails, replace the entire module (relays are not field-serviceable) with a GE-approved IS200DTRTH1A—third-party relays may not meet voltage/current ratings, risking fire or equipment damage.

Service and Guarantee Commitment

The IS200DTRTH1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and relay performance under normal Mark VI operation. If the module fails within this period (e.g., relay sticking, overcurrent protection failure), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize downtime—critical for plants relying on heavy-load auxiliaries for turbine operation.

GE offers 24/7 global technical support for the IS200DTRTH1A: certified Mark VI engineers specialize in relay control systems and assist with load calculation, wiring verification, and troubleshooting via phone, email, or remote access. Support includes guidance on relay lifespan management and compatibility checks for third-party heavy-load devices. Customers gain access to GE’s Digital Industrial Library, which includes the IS200DTRTH1A’s technical manual, relay application notes, and retrofit wiring guides.

For mission-critical applications (e.g., nuclear power plant cooling systems, offshore platform water injection), GE provides extended warranty options (up to 4 years) and semi-annual preventive maintenance—trained technicians perform relay contact testing, arc suppression validation, and isolation resistance checks to ensure the IS200DTRTH1A meets IEC 61508 SIL 2 safety standards. This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ heavy-load turbine systems operating safely and efficiently.