Description

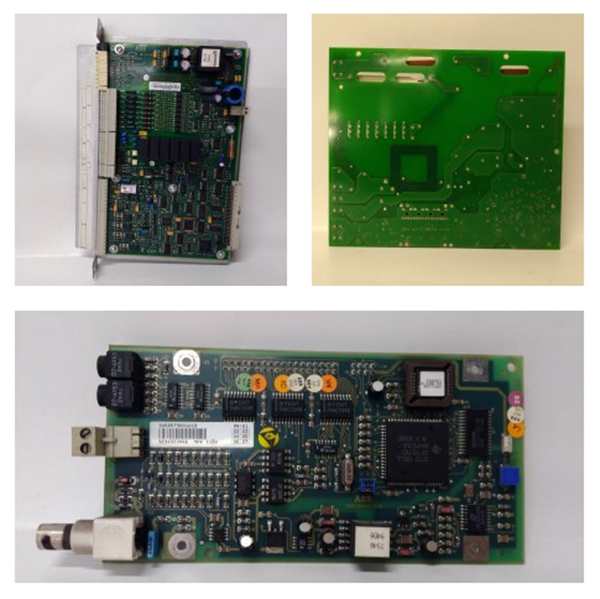

Professional Product Description: GE IS200DSPCH1A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200DSPCH1A |

| Manufacturer | General Electric (GE) |

| Product category | Digital Signal Processor Module (Mark VIe Speedtronic) |

| Processor | 32-bit floating-point DSP, 133 MHz |

| Data processing capacity | 266 MFLOPS |

| Memory | 64 MB DDR RAM; 32 MB flash; 2 MB SRAM |

| Input channels | 8 analog (16-bit, 250 kSPS); 4 digital/pulse (up to 250 kHz) |

| Communication interfaces | 2 x 10/100 Ethernet; 1 x USB; 1 x RS-485; Mark VIe backplane |

| Programming support | IEC 61131-3; GE algorithm library |

| Operating temperature | -40°C to +85°C |

| Power requirements | 24 VDC (±10%); 0.5 A max |

| Safety & EMC compliance | IEC 61010-1; EN 61326-1; UL 61010-1 |

| MTBF | 2,000,000 hours (at 40°C) |

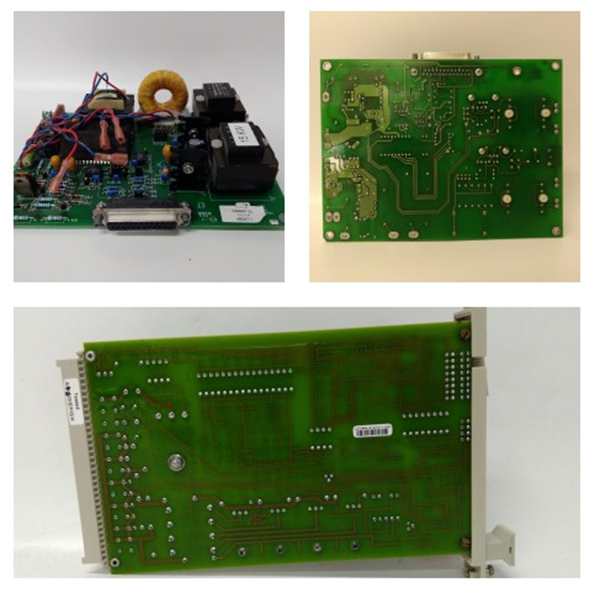

IS200EPBPG1A

Product Introduction

The IS200DSPCH1A is a robust digital signal processor module developed by GE for its Mark VIe Speedtronic turbine control system. As a key component in GE’s advanced turbine automation platform, this module serves as the “signal processing center” that transforms raw sensor data into meaningful control signals for efficient turbine operation.

Featuring a 133 MHz floating-point DSP delivering 266 MFLOPS of processing power, the IS200DSPCH1A provides the computational capability required for real-time data processing and algorithm execution. Its comprehensive I/O configuration includes 8 analog inputs (16-bit resolution at 250 kSPS) and 4 digital/pulse inputs (up to 250 kHz), enabling it to handle multiple sensor types simultaneously.

The IS200DSPCH1A plays a critical role in turbine control architectures by providing the processing power needed for advanced control strategies, condition monitoring, and performance optimization. Its rugged design ensures reliable operation in harsh power generation environments, including extreme temperatures, vibration, and electromagnetic interference.

Core Advantages and Technical Highlights

Reliable Signal Processing: The IS200DSPCH1A features a dedicated floating-point DSP that executes control algorithms with speed and precision. This capability is essential for implementing advanced control strategies that optimize turbine performance while maintaining safe operating margins.

Comprehensive Data Acquisition: With 8 high-resolution analog inputs and 4 high-speed digital inputs, the IS200DSPCH1A can simultaneously process data from multiple sensors throughout the turbine system. This includes temperature, pressure, vibration, and speed measurements critical for both control and monitoring applications.

Industrial-Grade Durability: Designed specifically for turbine control applications, the IS200DSPCH1A meets the demanding requirements of power generation environments. Its wide operating temperature range (-40°C to +85°C), rugged construction, and comprehensive EMC protection ensure reliable operation even in harsh conditions.

Seamless System Integration: The IS200DSPCH1A integrates seamlessly with other Mark VIe components through its dual Ethernet interfaces and backplane connection. This allows for efficient data exchange with the main controller and other system modules, creating a cohesive control architecture.

Flexible Programming: Supporting IEC 61131-3 programming standards along with GE’s specialized algorithm library, the IS200DSPCH1A offers flexibility in implementing custom control strategies. This allows engineers to develop application-specific solutions while leveraging GE’s extensive experience in turbine control.

Typical Application Scenarios

In gas turbine power plants, the IS200DSPCH1A processes data from key sensors including exhaust temperature thermocouples, compressor discharge pressure transducers, and rotor speed encoders. The module executes control algorithms that optimize fuel delivery and airflow to maintain efficient combustion while minimizing emissions.

For steam turbine applications, the IS200DSPCH1A processes steam pressure and temperature data, along with valve position feedback, to implement precise speed and load control. Its processing capabilities enable rapid response to load changes while maintaining stable operation.

In industrial cogeneration facilities, the IS200DSPCH1A coordinates between the turbine control system and auxiliary equipment such as heat recovery steam generators (HRSGs). It processes both electrical load demands and thermal requirements to optimize overall plant efficiency.

The IS200DSPCH1A is also used in condition monitoring applications, processing vibration data to detect early signs of mechanical issues. By analyzing vibration patterns in real-time, the module can identify potential problems before they escalate into major failures, enabling predictive maintenance strategies.

Related Model Recommendations

IS200HFPAG1A – High-frequency pulse acquisition module that provides speed and position data to the IS200DSPCH1A for turbine control applications.

IS200IVFBG1A – Voltage/frequency feedback module that supplies grid parameters to the IS200DSPCH1A for synchronization and power control functions.

IS200DTAIH1A – Digital input module that sends status signals from field devices to the IS200DSPCH1A for monitoring and interlock functions.

IS200DTAOH1A – Digital output module that executes control commands generated by the IS200DSPCH1A to operate valves, pumps, and other equipment.

IC698CPE030 – Mark VIe main controller that works in conjunction with the IS200DSPCH1A to provide comprehensive turbine control functionality.

IS200EACFG1A – Configuration module that stores the IS200DSPCH1A‘s program and parameters, enabling quick replacement and minimizing downtime.

IS200EHBQG2A – Backplane module that provides power and communication connectivity for the IS200DSPCH1A within the Mark VIe system.

IS200JGNDG1A – Grounding module that enhances signal integrity for the IS200DSPCH1A by reducing noise and preventing ground loops.

IS200EPBPG1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200DSPCH1A, ensure the Mark VIe backplane is powered down. Verify that the installation environment meets the module’s operating specifications (-40°C to +85°C). Use ESD-protective equipment and tools to prevent electrostatic damage. Check that the backplane slot is compatible with DSP modules and that the 24 VDC power supply meets the required specifications (±10% tolerance). Use shielded twisted-pair cables for all signal connections and ensure proper grounding according to GE guidelines.

Commissioning: After physical installation, configure the IS200DSPCH1A using GE’s ToolboxST software. Download the appropriate control program and parameter settings. Perform a complete system checkout, verifying all analog and digital inputs and outputs. Calibrate analog channels as required and verify communication with the main controller and other system components.

Maintenance suggestions: Regularly monitor the IS200DSPCH1A status through the Mark VIe HMI. Perform periodic diagnostic tests using ToolboxST to verify module health and performance. Inspect connections quarterly, tightening any loose terminals. Keep the module firmware updated to the latest version recommended by GE. If a failure occurs, first check power and communication connections before considering module replacement. Always use GE-approved replacement parts to ensure system compatibility and reliability.

Service and Guarantee Commitment

The IS200DSPCH1A comes with a 2-year standard warranty from GE, covering defects in materials and workmanship. GE’s global service network provides comprehensive support for the IS200DSPCH1A, including technical assistance, repair services, and spare parts availability.

GE offers 24/7 technical support for the IS200DSPCH1A, with specialists available to assist with installation, configuration, and troubleshooting. Customers have access to GE’s extensive library of technical documentation, including user manuals, application notes, and programming guides.

For mission-critical applications, GE provides extended warranty options and preventive maintenance services to ensure the IS200DSPCH1A operates at peak performance throughout its service life. GE’s commitment to quality and customer satisfaction ensures that the IS200DSPCH1A will provide reliable performance in even the most demanding turbine control applications.