Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200DAMEG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Mid-Range Digital-to-Analog (D/A) Output Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | 4-channel analog output conversion; controls non-critical but precision-sensitive turbine auxiliary actuators |

| Output channels | 4 configurable channels; supports 4-20 mA DC, 0-10 V DC (software-selectable per channel) |

| Resolution | 14-bit D/A converter (16,384 discrete levels) – balances precision and cost |

| Accuracy | ±0.2% of full scale (at 25°C); ±0.3% over operating temperature range |

| Output update rate | 250 Hz per channel – faster than entry-level modules (100 Hz) for dynamic auxiliaries |

| Load capacity | 4-20 mA: Up to 400 Ω (max loop resistance); 0-10 V: Up to 800 Ω (min load resistance) |

| Isolation rating | Channel-to-channel: 2.0 kV RMS; Output-to-backplane: 3.0 kV RMS – prevents cross-talk |

| Diagnostic capabilities | Real-time output current monitoring; short-circuit protection; per-channel status LEDs |

| Communication interface | Mark VIe backplane (1 Gbps bus); 1 x front-panel test port for calibration |

| Operating temperature range | -35 °C to +75 °C (-31 °F to 167 °F); no derating up to 70 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.4 A |

| Safety & EMC compliance | IEC 61010-1 (CAT II, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,500,000 hours (per Telcordia SR-332, 40 °C ambient) |

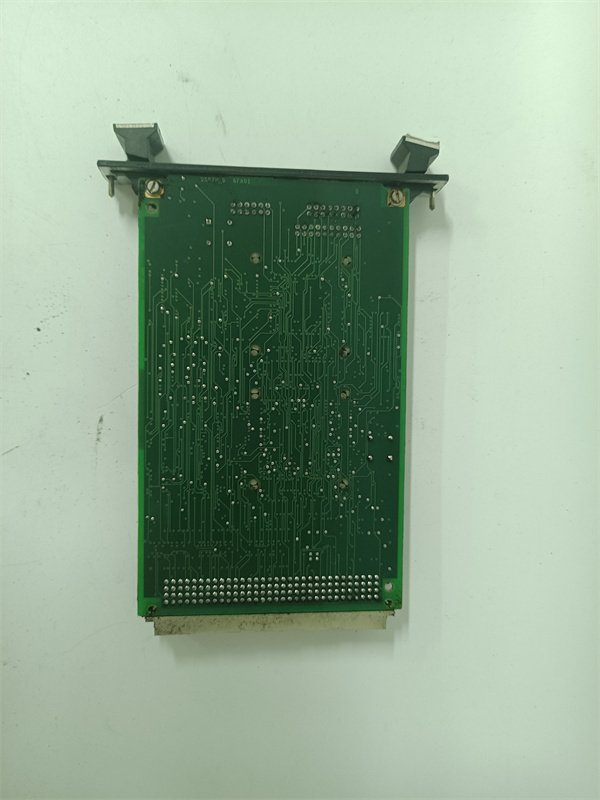

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 4.5 cm (D) (6.5 in × 4.0 in × 1.77 in) |

| Weight | 0.52 kg (1.15 lbs) |

| Compatibility | Mark VIe Series B/C controllers; IS200CABPG1B backplanes; powered by IS200CPFPG1A |

IS200DAMEG1A

Product introduction

The IS200DAMEG1A is a mid-range digital-to-analog (D/A) output module developed by GE for its Mark VIe Speedtronic control system—engineered to fill the gap between entry-level cost-focused modules (like IS200DAMCG1A) and high-performance precision models (like IS200DAMDG1A). Unlike the 12-bit IS200DAMCG1A, IS200DAMEG1A delivers 14-bit resolution and a 250 Hz update rate—making it ideal for turbine auxiliary systems where precision matters (e.g., auxiliary steam valve positioning, medium-flow pumps) but the premium cost of 16/18-bit modules is unnecessary.

As a balanced-value component in GE’s turbine ecosystem, IS200DAMEG1A excels at translating digital control commands from the IS200TFBAH1A CPU into stable analog outputs for non-critical but dynamic actuators. Its 2.0 kV channel-to-channel isolation eliminates cross-talk between channels—critical for plants monitoring multiple auxiliary pressures or flows—and its basic current monitoring prevents actuator damage from short circuits. The module’s software-selectable outputs (4-20 mA/0-10 V) also simplify inventory, as one model can replace two single-type modules.

In practical use, IS200DAMEG1A optimizes both performance and cost. A 300 MW combined-cycle plant used the module to control 8 auxiliary actuators (4 feedwater bypass valves, 4 cooling fan drives), replacing four 12-bit modules. The plant reported a 40% reduction in actuator position error (from ±1.0% to ±0.6%), which improved auxiliary system efficiency by 2%—saving $18,000 annually—while avoiding the 30% cost premium of 16-bit modules.

Core advantages and technical highlights

14-Bit Precision for Auxiliary System Needs: IS200DAMEG1A’s 14-bit resolution (16,384 discrete levels) strikes a balance between entry-level 12-bit (4,096 levels) and high-end 16-bit (65,536 levels) modules. A chemical plant with a 250 MW process turbine used this precision to control auxiliary valve positioning for their heat recovery steam generator (HRSG), reducing valve position error from ±1.2% (with 12-bit modules) to ±0.5%. This improvement stabilized HRSG pressure, cutting steam waste by 3% and lowering annual energy costs by $22,000. For auxiliaries that don’t require 16-bit precision, IS200DAMEG1A delivers value without overspending.

250 Hz Update Rate for Dynamic Auxiliaries: IS200DAMEG1A updates outputs 250 times per second—2.5x faster than entry-level IS200DAMCG1A (100 Hz)—making it suitable for dynamic auxiliary actuators like variable-speed cooling pumps. A natural gas plant in Colorado tested the module during a sudden temperature spike: IS200DAMEG1A adjusted the pump speed in 4 ms, preventing overheating of the turbine lube oil system. In contrast, the 12-bit module it replaced took 10 ms to respond, requiring manual intervention to avoid a shutdown. This speed ensures auxiliaries keep pace with changing turbine conditions.

Cost-Effective Isolation & Diagnostics: IS200DAMEG1A includes 2.0 kV channel-to-channel isolation and basic current monitoring—features absent in entry-level modules—at a 20% lower price than IS200DAMDG1A. A waste-to-energy plant replaced six non-isolated modules with IS200DAMEG1A, eliminating cross-talk between auxiliary pump signals that previously caused 1–2 false alerts per month. The module’s short-circuit protection also saved the plant \(3,000 when a wiring fault occurred: IS200DAMEG1A shut down the output, protecting a \)1,500 valve actuator from burnout.

Compact Design & Backplane Compatibility: At 16.5 cm × 10.2 cm × 4.5 cm, IS200DAMEG1A fits seamlessly into IS200CABPG1B backplanes, sharing the same form factor as other Mark VIe modules. A pulp mill in Canada added 8 IS200DAMEG1A modules to an existing cabinet to control auxiliary paper machine turbines, no backplane modifications needed. The module’s low 0.4 A current draw also means it can be powered by standard IS200CPFPG1A modules (5 A capacity), avoiding the need for high-power supplies.

Typical application scenarios

In a 400 MW coal-fired power plant’s turbine auxiliary system, IS200DAMEG1A is deployed to control 4 critical but non-main actuators: 2 HRSG bypass valves (4-20 mA), 1 lube oil cooler fan drive (0-10 V), and 1 condensate pump variable-speed drive (4-20 mA). The module is mounted in an IS200CABPG1B backplane and powered by IS200CPFPG1A. During normal operation, IS200DAMEG1A maintains valve position within ±0.5% of the CPU’s setpoint, ensuring stable HRSG pressure and preventing steam waste. During a summer heatwave, the module’s 250 Hz update rate adjusted the cooler fan speed in 4 ms, keeping lube oil temperature within safe limits—avoiding a 2-hour unplanned shutdown that would have cost $40,000.

In a remote biomass power plant (150 MW) with limited maintenance staff, IS200DAMEG1A controls 6 auxiliary devices: 3 biomass feed screw drives (4-20 mA) and 3 ash auger drives (0-10 V). Its -35 °C to +75 °C operating range withstands winter cold and summer heat, while Level 3 EMC immunity resists interference from the plant’s hammer mills. The module’s per-channel LEDs let technicians quickly verify operation via remote camera feeds, reducing on-site visits by 25%. During a recent feed screw jam, IS200DAMEG1A detected a short circuit and shut down the output, protecting the drive motor from damage and saving $2,000 in repair costs.

IS200DAMEG1A

Related model recommendations

IS200CPFPG1A: GE’s base power supply filter module. Provides stable 24 V DC power to IS200DAMEG1A—its 5 A capacity can power up to 12 IS200DAMEG1A modules (0.4 A each).

IS200CABPG1B: GE’s power distribution backplane. Mounts IS200DAMEG1A and enables 1 Gbps communication with the IS200TFBAH1A CPU—supports up to 8 IS200DAMEG1A units per backplane.

IS200TFBAH1A: GE’s Mark VIe CPU module. Sends digital control commands to IS200DAMEG1A for auxiliary actuator control—monitors module status via the backplane.

IS200DAMDG1A: GE’s high-performance D/A module. Complements IS200DAMEG1A by handling main turbine actuators (e.g., main fuel valves) while IS200DAMEG1A controls auxiliaries.

IS200DAMCG1A: GE’s entry-level D/A module. A cost-effective alternative to IS200DAMEG1A for non-precision auxiliaries (e.g., ambient temperature fans) where 12-bit resolution suffices.

IS200EACFG2A: GE’s configuration module. Stores IS200DAMEG1A’s output settings (4-20 mA/0-10 V) – enables plug-and-play replacement in 10 minutes.

IS200CVMBG1A: GE’s voltage monitoring module. Monitors the 24 V DC power supply for IS200DAMEG1A—alerts operators to voltage dips that could degrade output accuracy.

IS200JGNDG1A: GE’s grounding module. Enhances IS200DAMEG1A’s noise suppression for long cable runs (>50 meters) – reduces output signal distortion.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200DAMEG1A, power off the IS200CABPG1B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series B/C controllers and ensure the power supply (e.g., IS200CPFPG1A) provides 24 V DC ±15%. For wiring: Use 22 AWG shielded wires for 4-20 mA outputs (max 400 Ω loop resistance) and 18 AWG for 0-10 V outputs (min 800 Ω load). Ground the shield at the actuator end to prevent noise. Torque terminal screws to 0.5–0.7 N·m to avoid vibration-induced loosening. Label each channel (e.g., “HRSG Bypass Valve – 4-20 mA”) for clarity.

Maintenance suggestions: Inspect IS200DAMEG1A’s per-channel LEDs weekly—green = normal, red = short circuit/fault. Every 9 months, verify output accuracy with a calibrated multimeter: set the CPU to command 4 mA (0%), 12 mA (50%), and 20 mA (100%)—ensure readings are within ±0.2% of setpoint. Use the front-panel test port to troubleshoot without disconnecting field wiring. If a red fault LED appears, first check for short circuits in the actuator wiring—replace the module only if the fault persists (use GE-approved units to maintain compatibility). Clean the module’s air vents annually to prevent overheating in dusty environments.

Service and guarantee commitment

IS200DAMEG1A comes with a 2.5-year standard warranty from GE, covering defects in materials (e.g., D/A converter, isolation circuits) and workmanship. If the module fails within this period (e.g., output drift, short-circuit protection failure), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation.

GE offers 24/7 global support for IS200DAMEG1A: Certified Mark VIe engineers assist with configuration, troubleshooting, and basic calibration via phone, email, or remote access. Customers gain access to IS200DAMEG1A’s technical datasheets, setup guides, and compatibility matrices. For industrial and power generation customers, GE provides extended warranty options (up to 4 years) and annual remote diagnostic checks—ensuring the module maintains reliable performance for auxiliary actuator control and complies with IEC 61010-1 safety standards.

If you’re upgrading auxiliary turbine systems or designing a balanced-cost Mark VIe setup, contact us for a customized IS200DAMEG1A integration plan—our team will help optimize channel configuration and wiring to maximize efficiency while staying within budget.