Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

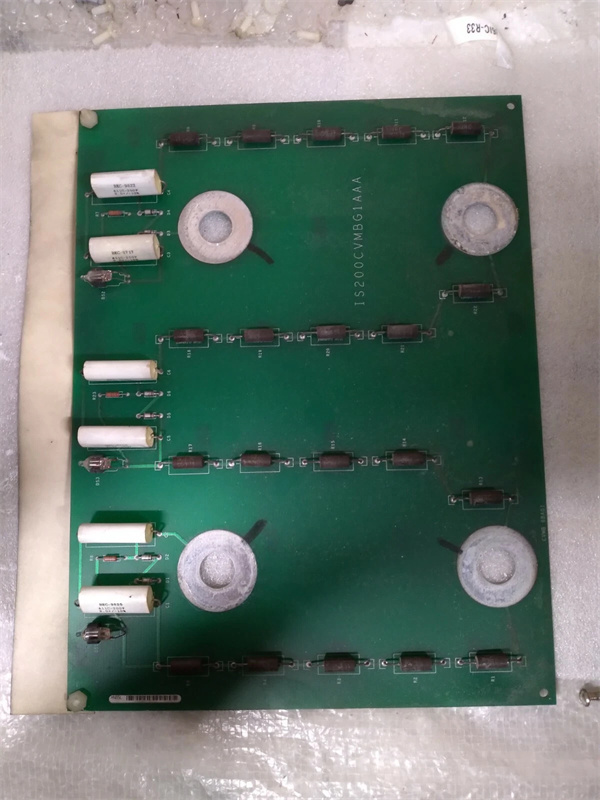

| Product model | IS200CVMBG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Control Voltage Monitoring & Buffer Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Multi-channel voltage monitoring, voltage anomaly detection, event data buffering, and status feedback for critical power supplies |

| Monitoring channels | 6 configurable channels; supports 5 V DC, 12 V DC, 24 V DC, 48 V DC, 125 V DC (software-selectable) |

| Voltage measurement range | 0–150 V DC (full scale); accuracy: ±0.2% of measured value (at 25°C) |

| Sampling rate | 50 samples per second (SPS) per channel – captures gradual voltage drifts and sudden spikes |

| Buffer capacity | 1 GB non-volatile Flash memory; stores up to 90 days of voltage event logs (1 event/minute) |

| Alarm thresholds | Configurable overvoltage/undervoltage thresholds (e.g., 24 V DC: 22 V (low) / 26 V (high)) |

| Communication interface | Mark VIe backplane (1 Gbps bus); 1 x RS-485 port (Modbus RTU) for remote voltage monitoring |

| Output signals | 2 digital alarm outputs (Form A, 2 A@24 V DC) – triggers alerts for voltage anomalies |

| Operating temperature range | -30 °C to +75 °C (-22 °F to 167 °F); no derating up to 70 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.3 A |

| Safety & EMC compliance | IEC 61010-1 (CAT II, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,800,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 4.5 cm (D) (6.5 in × 4.0 in × 1.77 in) |

| Weight | 0.51 kg (1.1 lbs) |

| Compatibility | Mark VIe Series B/C backplanes (IS200CABPG1B); monitors power from IS200CPFPG1A/IS200CPFXG1A |

IS200CVMBG1A

Product introduction

The IS200CVMBG1A is a dedicated control voltage monitoring and buffer module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “power health guardian” that ensures critical power supplies (like those from IS200CPFPG1A or IS200CPFXG1A) remain stable and predictable. Unlike generic voltage monitors that only alert on faults, IS200CVMBG1A integrates 6 configurable monitoring channels, event buffering, and remote communication—making it a one-stop solution for tracking voltage health across turbine control systems.

As a stability-focused component in GE’s turbine ecosystem, IS200CVMBG1A addresses a common but underappreciated risk: voltage fluctuations that degrade module performance or trigger false shutdowns. For example, it monitors the 24 V DC supply powering IS200BPIHH1A (analog input) and IS200DAMDG1A (D/A output) modules—if voltage drops below 22 V or rises above 26 V, the module triggers a digital alarm and logs the event. Its 1 GB buffer also stores 90 days of voltage data, enabling technicians to trace intermittent issues (e.g., nightly voltage dips) that standard monitors miss.

In practical use, IS200CVMBG1A prevents costly downtime caused by power-related failures. A 400 MW combined-cycle plant in Texas installed the module to monitor 6 critical voltages: 24 V DC (I/O power), 125 V DC (relay power), and 48 V DC (communication bus). Within 2 months, IS200CVMBG1A detected a recurring 23 V DC dip (caused by a faulty UPS) that was causing IS200DAMDG1A to lose calibration. Fixing the UPS prevented 3 potential turbine trips and saved $80,000 in unplanned maintenance.

Core advantages and technical highlights

Configurable Multi-Channel Monitoring: IS200CVMBG1A’s 6 software-selectable channels support voltages from 5 V DC to 125 V DC—eliminating the need for multiple single-voltage monitors. A chemical plant replaced 4 dedicated monitors (for 5 V, 24 V, 48 V, and 125 V) with one IS200CVMBG1A, reducing backplane space by 60% and simplifying wiring. The module’s ±0.2% measurement accuracy also ensures reliable data—critical for tracking small voltage drifts (e.g., 0.5 V drop in 24 V DC) that indicate failing power supplies.

Long-Term Event Buffering for Troubleshooting: With 1 GB of non-volatile Flash memory, IS200CVMBG1A stores up to 90 days of voltage events—even during power outages. A wind farm in Iowa used this feature to diagnose an intermittent voltage spike (125 V DC jumping to 135 V) that occurred only during high-wind events. By reviewing 2 weeks of buffered data, technicians traced the spike to a loose UPS connection—fixing it before it damaged IS200TRLYH2C relay modules. This capability reduces troubleshooting time from weeks to hours compared to monitors with no buffering.

Remote Monitoring via RS-485: Unlike basic voltage monitors that require on-site checks, IS200CVMBG1A includes an RS-485 port (Modbus RTU) for remote voltage tracking. A utility company with 20 distributed turbine sites uses this to monitor IS200CVMBG1A data from a central SCADA system. Technicians receive real-time alerts for voltage anomalies (e.g., 24 V DC dropping to 21 V) and can review historical trends without visiting each site—cutting on-site maintenance visits by 35%.

Digital Alarm Outputs for Rapid Response: IS200CVMBG1A’s 2 Form A digital outputs trigger immediate actions (e.g., activating a backup UPS, alerting the Mark VIe CPU) when voltage exceeds thresholds. A coal-fired plant in Indiana wired one output to a backup power supply: when IS200CVMBG1A detected a 24 V DC drop to 21.5 V, the output activated the backup in 50 ms—preventing IS200BPIHH1A from losing pressure sensor data. This proactive response avoids the “wait-and-see” delays of software-only alarms.

Typical application scenarios

In a 600 MW combined-cycle power plant with two GE 7HA gas turbines, IS200CVMBG1A is deployed to monitor 6 critical power supplies in each turbine’s control cabinet: 24 V DC (from IS200CPFXG1A for I/O modules), 125 V DC (relay power), 48 V DC (communication bus), 12 V DC (sensor power), and two redundant 24 V DC supplies (primary/backup). During a summer grid peak, the module detected a 24 V DC dip to 21.8 V (caused by increased load on the main power supply) and triggered a digital alarm. The Mark VIe CPU responded by switching to the backup IS200CPFXG1A supply, maintaining stable power for IS200DAMDG1A and IS200BPIHH1A—avoiding a turbine trip that would have cost $50,000 in lost production. The module’s buffered data also helped technicians identify the main supply’s declining capacity, scheduling a replacement during a planned outage.

In a remote biomass power plant (with limited on-site staff), IS200CVMBG1A monitors 4 key voltages and transmits data to a central SCADA system via RS-485. One night, the module alerted operators to a 125 V DC spike (to 132 V) caused by a faulty voltage regulator. Operators remotely shut down non-critical systems to reduce load, while dispatching a technician the next day. The buffered log showed the spike occurred 3 times in 2 hours—providing critical context for the repair. Without IS200CVMBG1A, the spike would have damaged IS200TRLYH1C relays, leading to a 12-hour unplanned shutdown.

Related model recommendations

IS200CPFPG1A: GE’s base power supply filter module. IS200CVMBG1A monitors its 24 V DC output to ensure stable power for I/O modules like IS200BPIHH1A.

IS200CPFXG1A: GE’s enhanced power supply filter module. IS200CVMBG1A tracks its dual redundant inputs (AC + DC backup) to verify failover performance.

IS200CABPG1B: GE’s power distribution backplane. IS200CVMBG1A mounts in its slot to monitor voltage across the backplane’s 8 module slots.

IS200DAMDG1A: GE’s precision D/A output module. Relies on IS200CVMBG1A-monitored 24 V DC power—voltage fluctuations degrade its actuation accuracy.

IS200EACFG2A: GE’s configuration module. Stores IS200CVMBG1A’s alarm thresholds and channel settings—enables plug-and-play replacement.

IS200JGNDG1A: GE’s grounding module. Enhances IS200CVMBG1A’s measurement accuracy by reducing ground loops that cause voltage reading errors.

IS200TDBTH6A: GE’s data buffer module. Integrates with IS200CVMBG1A to store extended voltage event logs (beyond 90 days) for compliance reporting.

GE UPS5000: GE’s uninterruptible power supply. Triggered by IS200CVMBG1A’s digital alarm output to provide backup power during voltage dips.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200CVMBG1A, power off the IS200CABPG1B backplane and use ESD-safe tools. Verify the backplane slot is compatible with Mark VIe monitoring modules and ensure the module’s 24 V DC power supply (from a dedicated source, not the monitored voltages) meets ±15% tolerance. For wiring: Connect monitored voltages to the module’s 6 input terminals using 22 AWG shielded wires (ground shield at the power supply end); wire digital alarm outputs to the backup UPS or Mark VIe CPU. Label each channel (e.g., “24 V DC – I/O Power”) to avoid confusion.

Maintenance suggestions: Inspect IS200CVMBG1A’s status LEDs weekly—green = normal, amber = voltage warning, red = critical fault. Every 3 months, download buffered event logs via RS-485 to review voltage trends (e.g., gradual 24 V DC drift). Calibrate the module annually using a precision voltage source (e.g., Fluke 5520A) to ensure ±0.2% accuracy—adjust thresholds in ToolboxST if needed. If a red fault LED appears, first check the monitored voltage supply (e.g., replace a failing IS200CPFPG1A) before replacing IS200CVMBG1A. Always use GE-approved replacements to maintain compatibility with Mark VIe systems.

Service and guarantee commitment

IS200CVMBG1A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., voltage measurement circuits, buffer memory) and workmanship. If the module fails within this period (e.g., inaccurate readings, buffer corruption), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation and reconfiguration.

GE offers 24/7 global support for IS200CVMBG1A: Certified Mark VIe engineers assist with threshold setup, remote monitoring configuration, and log analysis via phone, email, or remote access. Customers gain access to IS200CVMBG1A’s calibration guides, voltage troubleshooting checklists, and compatibility matrices. For mission-critical systems (e.g., nuclear auxiliaries, grid-stabilizing turbines), GE provides extended warranties (up to 5 years) and semi-annual on-site calibration services—ensuring the module maintains ±0.2% accuracy and complies with IEC 61010-1 safety standards, keeping turbine power supplies stable and reliable.