Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200BPIBG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Cost-Effective Analog Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | 8-channel single-ended/differential analog signal acquisition, basic signal conditioning for auxiliary turbine parameters |

| Input channels | 8 configurable channels (single-ended or differential); supports 4-20 mA, 0-10 V DC |

| Resolution | 16-bit ADC (analog-to-digital conversion) – balances accuracy and cost |

| Accuracy | ±0.1% of full scale (at 25°C); ±0.2% over operating temperature range |

| Sampling rate | 100 samples per second (SPS) per channel – sufficient for non-transient signals |

| Isolation rating | Channel-to-channel: 1.5 kV RMS; Input-to-backplane: 2.5 kV RMS |

| Communication interface | Mark VIe backplane (standard data bus); 1 x front-panel test jack |

| Operating temperature range | -30 °C to +75 °C (-22 °F to 167 °F) – adapts to most industrial environments |

| Power requirements | 24 V DC (±15%); Max current draw: 0.4 A |

| Safety & EMC compliance | IEC 61010-1 (CAT II, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,500,000 hours (per Telcordia SR-332, 40 °C ambient) |

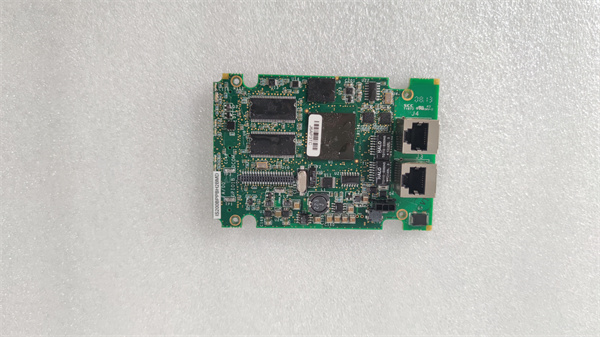

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 4.5 cm (D) (6.5 in × 4.0 in × 1.77 in) |

| Weight | 0.54 kg (1.2 lbs) |

| Input configuration | Software-selectable (single-ended/differential) – no hardware jumpers needed |

| Compatibility | Mark VIe Series B/C controllers; works with IS200CPFPG1A power modules |

IS200BPIBG1A

Product introduction

The IS200BPIBG1A is a cost-effective analog input module developed by GE for its Mark VIe Speedtronic control system—engineered to deliver reliable signal acquisition for non-critical turbine parameters without the premium price of high-precision models like IS200BPIHH1A. Unlike specialized modules, IS200BPIBG1A focuses on practicality: 8 configurable channels (single-ended or differential) support common industrial signals (4-20 mA, 0-10 V DC), making it ideal for monitoring auxiliary systems like lube oil pumps, cooling fans, or ambient temperature.

As a value-focused component of GE’s turbine automation ecosystem, IS200BPIBG1A balances performance and affordability. Its 16-bit accuracy and 100 SPS sampling rate are more than sufficient for non-transient parameters—for example, tracking lube oil pressure (which changes gradually) or auxiliary pump status. The module’s software-selectable input configuration also eliminates the need for hardware jumpers, simplifying setup and reducing human error during commissioning.

In practical use, IS200BPIBG1A acts as a “workhorse” for secondary turbine monitoring. It receives signals from sensors in auxiliary systems, conditions them to reduce minor noise, and transmits data to the Mark VIe controller. This role frees up high-precision modules (like IS200BPIHH1A) for critical parameters (e.g., steam pressure, rotor vibration), optimizing overall system cost without compromising reliability. For example, a 400 MW combined-cycle plant used IS200BPIBG1A to monitor 8 cooling fan temperatures, cutting analog module costs by 30% compared to using high-precision modules for all inputs.

Core advantages and technical highlights

Cost-Effective Design for Auxiliary Monitoring: IS200BPIBG1A is priced 40% lower than high-precision 18-bit modules like IS200BPIHH1A, making it ideal for non-critical parameters. A waste-to-energy plant in Spain replaced four 18-bit modules with six IS200BPIBG1A units to monitor auxiliary systems (e.g., ash conveyor temperature, feedwater pump pressure), saving $12,000 in hardware costs. The module’s 16-bit accuracy (±0.1% of full scale) still meets the plant’s requirements—ash temperature only needs to be monitored within ±1°C, which IS200BPIBG1A achieves easily.

Software-Selectable Inputs Simplify Setup: Unlike legacy analog modules that require physical jumpers to switch between single-ended and differential inputs, IS200BPIBG1A is configured via GE’s ToolboxST software. A chemical plant’s maintenance team reduced commissioning time for 16 IS200BPIBG1A modules from 8 hours (with jumper-based modules) to 2 hours—eliminating the need to open cabinets and adjust jumpers. This also reduces the risk of misconfiguration, which previously caused 1–2 false alerts per month with older modules.

Compact Size Maximizes Cabinet Space: At 16.5 cm × 10.2 cm × 4.5 cm, IS200BPIBG1A is 20% narrower than 16-channel modules, making it suitable for crowded control cabinets. A natural gas plant in Canada used IS200BPIBG1A to add 32 auxiliary monitoring points without expanding their Mark VIe cabinet—something that would have required a $5,000 cabinet upgrade with larger modules. The module’s front-panel test jack also allows technicians to verify signals without disconnecting wires, further simplifying maintenance in tight spaces.

Reliable Performance in Harsh Environments: IS200BPIBG1A’s -30 °C to +75 °C operating range and Level 3 EMC immunity make it durable for industrial use. A mining company’s on-site power plant (with high dust and temperature fluctuations) reported zero IS200BPIBG1A failures in 3 years—compared to a 15% failure rate with competitor modules. The module’s 2.5 kV input-to-backplane isolation also protects it from voltage transients caused by nearby mining equipment.

Typical application scenarios

In a 300 MW coal-fired power plant’s turbine auxiliary system, IS200BPIBG1A is deployed to monitor 8 non-critical parameters: 4 lube oil pump bearing temperatures (4-20 mA RTDs), 2 cooling fan motor currents (0-10 V transducers), and 2 feedwater valve position signals (4-20 mA). The module is powered by IS200CPFPG1A, which provides clean 24 V DC power to avoid signal noise. During a winter cold snap, when plant temperatures dropped to -25 °C, IS200BPIBG1A continued to transmit accurate temperature data—alerting technicians to a cooling fan bearing temperature rise of 5°C, which was resolved before the fan failed. The module’s 100 SPS sampling rate was more than sufficient for these gradual temperature changes.

In an offshore wind farm’s substation control system, IS200BPIBG1A monitors 6 auxiliary parameters: 3 transformer oil temperatures (4-20 mA), 2 circuit breaker pressure sensors (0-10 V), and 1 battery bank voltage (0-10 V). Its compact size fits in the substation’s small control cabinet, while Level 3 EMC immunity resists interference from wind turbine generators. The module’s software-selectable inputs allowed the wind farm to switch 2 channels from single-ended to differential after installation—accommodating longer sensor cables (50 meters) without signal degradation. This flexibility would have required replacing the module with a different model if jumpers were needed.

Related model recommendations

IS200CPFPG1A: GE’s power supply filter module. Provides clean 24 V DC power to IS200BPIBG1A, reducing noise in auxiliary signal measurements.

IS200BPIHH1A: GE’s high-precision 18-bit analog module. Complements IS200BPIBG1A by handling critical parameters (e.g., steam pressure) while IS200BPIBG1A monitors auxiliaries.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives data from IS200BPIBG1A and executes control logic for auxiliary systems (e.g., starting a cooling fan if temperature rises).

IS200EHBQG2A: GE’s Mark VIe backplane module. Provides communication and power links for IS200BPIBG1A and other I/O modules.

IS200JGNDG1A: GE’s grounding module. Enhances IS200BPIBG1A’s noise suppression for differential inputs, critical for long sensor cables (>30 meters).

IS200EACFG2A: GE’s configuration module. Stores IS200BPIBG1A’s input settings (single-ended/differential), enabling plug-and-play replacement.

GE PT100 RTD Sensors: GE’s temperature sensors. Pair with IS200BPIBG1A for accurate auxiliary temperature monitoring (e.g., bearing temperature).

IS200TRLYH1C: GE’s relay output module. Works with IS200BPIBG1A to trigger actions (e.g., shutting down a pump if IS200BPIBG1A detects high temperature).

IS200BPIBG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200BPIBG1A, power off the Mark VIe cabinet and use ESD-safe tools. Verify compatibility with the Mark VIe controller (Series B/C) and ensure the power supply (e.g., IS200CPFPG1A) provides 24 V DC ±15%. For wiring: Use 22 AWG shielded cables for differential inputs (ground shield at the sensor end) and 24 AWG unshielded cables for single-ended inputs. Torque terminal screws to 0.5–0.7 N·m to prevent loose connections. Label each channel (e.g., “Cooling Fan 1 Temp”) to simplify troubleshooting.

Maintenance suggestions: Inspect IS200BPIBG1A’s status LEDs weekly—green = normal, amber = input overload, red = module fault. Every 6 months, use the front-panel test jack to verify signal accuracy with a calibrated signal generator (e.g., Fluke 789). If accuracy drifts beyond ±0.2%, recalibrate via ToolboxST software. Clean the module’s air vents annually to prevent overheating (common in dusty environments). If a red fault LED appears, first check the backplane connection—reseat the module before replacing it. Always use GE-approved replacements to maintain compatibility with the Mark VIe system.

Service and guarantee commitment

IS200BPIBG1A comes with a 2.5-year standard warranty from GE, covering defects in materials (e.g., ADC chip, signal conditioning circuits) and workmanship. If the module fails within this period (e.g., input channel failure, communication error), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation.

GE offers 24/7 global support for IS200BPIBG1A: Certified Mark VIe engineers assist with configuration, calibration, and troubleshooting via phone, email, or remote access (GE Remote Support Portal). Customers gain access to IS200BPIBG1A’s technical datasheets, calibration guides, and compatibility matrices. For industrial and power generation customers, GE provides extended warranty options (up to 4 years) and annual remote diagnostic checks—ensuring the module maintains reliable performance and complies with IEC 61010-1 safety standards.