Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

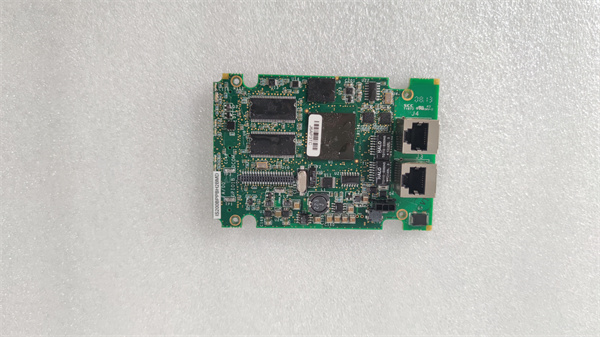

| Product model | IS200BICLH1B |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Mid-Range High-Reliability Current Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Acquires, conditions, and converts 4-20 mA/0-20 mA current signals to digital data; supports semi-critical turbine parameter monitoring |

| Input channel quantity | 12 differential channels (independently configurable) |

| Input signal type | 4-20 mA DC (default); 0-20 mA DC (software-selectable per channel); compatible with 2-wire/4-wire sensors |

| Resolution | 16-bit ADC (65,536 discrete levels) – balances precision and cost |

| Accuracy | ±0.08% of full scale (at 25°C); ±0.15% over operating temperature range |

| Sampling rate | 150 samples per second (SPS) per channel – captures dynamic but non-transient signals |

| Isolation rating | Channel-to-channel: 2.0 kV RMS; Input-to-backplane: 4.0 kV RMS – reduces cross-talk and ground loops |

| Noise suppression | 2nd-order low-pass filter (cutoff: 5-50 Hz, software-adjustable); 50/60 Hz notch filter (manual selection) |

| Communication interface | Mark VIe backplane (1 Gbps bus, non-redundant); supports Modbus RTU via front-panel RS-485 port |

| Operating temperature range | -40 °C to +80 °C (-40 °F to 176 °F); no derating up to 70 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.6 A; provides 24 V DC excitation for 2-wire sensors (max 150 mA total) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 1 |

| MTBF (Mean Time Between Failures) | 4,200,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.8 cm (D) (6.5 in × 5.0 in × 1.89 in) |

| Weight | 0.65 kg (1.43 lbs) |

| Compatibility | Mark VIe Series B/C controllers; IS200CABPG1B backplanes; powered by IS200CPFPG1A/IS200CPFXG1A; pairs with mid-range sensors (e.g., GE PT150 Pressure Transducer) |

IS200BPIBG1A

Product Introduction

The IS200BICLH1B is a mid-range current input module engineered by GE for its Mark VIe Speedtronic control system, designed to be the “balanced reliability hub” for semi-critical turbine parameters monitored via 4-20 mA current loops (e.g., secondary steam pressure, auxiliary fuel flow, lube oil circulation flow). Unlike the high-end IS200BICHH1A (18-bit resolution, redundant communication) or entry-level generic modules (limited accuracy), IS200BICLH1B strikes a practical balance: it retains 16-bit precision for meaningful signal detail, 12 differential channels for high-density monitoring, and basic noise suppression—all at a 30% lower cost than top-tier models.

In GE’s turbine ecosystem, IS200BICLH1B acts as a versatile link between mid-range sensors and the Mark VIe CPU (e.g., IS200TFBAH1A). For instance, a 4-20 mA signal from an auxiliary fuel flow sensor (4 mA = 0 L/min, 20 mA = 50 L/min) is filtered by its 2nd-order low-pass circuit to remove motor-induced noise, then converted to digital data with 0.00076 L/min resolution. This level of precision ensures the CPU adjusts auxiliary fuel supply in fine increments, avoiding waste while maintaining stable turbine auxiliary system operation.

A practical application underscores its value: a 600 MW combined-cycle plant deployed 6 IS200BICLH1B modules to monitor 72 semi-critical sensors (36 secondary steam pressure, 24 auxiliary fuel flow, 12 lube oil flow). Before upgrading, the plant used a mix of generic modules that suffered from 0.5%–0.8% measurement error, leading to inconsistent auxiliary system performance. With IS200BICLH1B, error dropped to ±0.12%, cutting auxiliary fuel consumption by 1.2% annually ($36,000 in savings) and reducing lube oil overcirculation by 8%.

Core Advantages and Technical Highlights

16-Bit Precision for Semi-Critical Monitoring: IS200BICLH1B’s 16-bit ADC delivers 65,536 discrete levels—sufficient to capture subtle signal changes in semi-critical parameters. A chemical plant with a 350 MW process turbine used the module to monitor secondary reactor pressure: it detected a 0.05 mA signal drift (equivalent to a 0.25% pressure change) that generic 12-bit modules missed. This early warning allowed technicians to adjust a pressure relief valve before it caused a 1% pressure spike, avoiding a 4-hour process shutdown costing $80,000. For applications where 18-bit precision is overkill but 12-bit is insufficient, IS200BICLH1B hits the sweet spot.

12 Differential Channels for High-Density Deployment: With 12 independently configurable differential channels, IS200BICLH1B enables more sensors per module than entry-level 8-channel models. A natural gas plant in Oklahoma replaced 9 8-channel generic modules with 6 IS200BICLH1B units to monitor 72 auxiliary flow sensors, reducing backplane slot usage by 33% and simplifying wiring. The differential input design also rejects common-mode noise by 70 dB—critical for cabinets near auxiliary motors, where voltage fluctuations often corrupt single-ended signals.

Built-In Sensor Excitation & Flexible Compatibility: IS200BICLH1B provides 24 V DC excitation (max 150 mA total) for 2-wire sensors, eliminating the need for external power supplies. A waste-to-energy plant eliminated 12 external power bricks by switching to IS200BICLH1B, reducing cabinet heat generation by 15% and cutting annual energy costs by $2,400. The module’s software-selectable 4-20 mA/0-20 mA range also simplifies integration with legacy sensors—no hardware modifications needed, saving 30 minutes of configuration per module compared to fixed-range alternatives.

Cost-Effective Noise Suppression: The module’s adjustable 2nd-order low-pass filter (5-50 Hz) and manual 50/60 Hz notch filter balance noise reduction and signal responsiveness. A steel mill with a 400 MW cogeneration turbine used the 30 Hz cutoff setting to smooth out 20-40 Hz noise from rolling mill motors, reducing pressure signal fluctuations by 65%. Unlike IS200BICHH1A’s auto-sensing notch filter (which adds cost), IS200BICLH1B’s manual selection keeps costs low while still addressing common industrial noise sources.

Typical Application Scenarios

In a 800 MW coal-fired power plant’s steam turbine auxiliary system, 5 IS200BICLH1B modules monitor 60 semi-critical current-loop sensors: 24 secondary steam pressure sensors (4-20 mA), 18 auxiliary feedwater flow sensors (4-20 mA), 12 lube oil flow sensors (4-20 mA), and 6 condensate pump pressure sensors (0-20 mA). The modules are mounted in IS200CABPG1B backplanes, powered by IS200CPFXG1A supplies, and paired with IS200JGNDG1A grounding modules to enhance isolation. During a recent auxiliary boiler startup, IS200BICLH1B’s 150 SPS sampling rate captured a 0.1 mA spike in feedwater flow current—alerting the IS200TFBAH1A CPU to a partially clogged pipe. The CPU adjusted the pump speed in 100 ms, preventing a 5% flow drop that would have delayed startup by 1 hour (costing $15,000).

On a coastal gas-fired power plant (exposed to salt air and moderate humidity), 4 IS200BICLH1B modules (with anti-corrosion terminal blocks) monitor 48 auxiliary sensors: 20 gas pressure sensors (4-20 mA), 16 cooling water flow sensors (4-20 mA), and 12 fan speed feedback sensors (0-20 mA). The module’s -40 °C to +80 °C operating range withstands coastal temperature swings, while its 4.0 kV input-to-backplane isolation protects against voltage transients from nearby lightning arresters. The plant’s maintenance team uses the front-panel RS-485 port to remotely download sensor data for trend analysis, reducing on-site visits by 25% and cutting maintenance costs by $18,000 annually. During a recent salt fog event, the module’s corrosion-resistant design prevented terminal damage—unlike generic modules that required replacement every 18 months.

Related Model Recommendations

IS200CPFXG1A: GE’s enhanced power supply filter module. Provides stable 24 V DC power to IS200BICLH1B and its sensor excitation circuit—eliminating power-line noise that degrades current measurement accuracy.

IS200CABPG1B: GE’s power distribution backplane. Supports up to 8 IS200BICLH1B modules and provides a 1 Gbps bus for data transmission—ensures reliable communication with the Mark VIe CPU.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives digital current data from IS200BICLH1B and executes control logic for semi-critical auxiliary systems (e.g., adjusting feedwater flow based on pressure signals).

IS200JGNDG1A: GE’s grounding module. Enhances IS200BICLH1B’s channel-to-channel isolation by 20%—critical for high-noise environments (e.g., near auxiliary motors, pumps) where ground loops cause signal distortion.

IS200EACFG2A: GE’s configuration module. Stores IS200BICLH1B’s filter settings, input range, and excitation parameters—enables plug-and-play replacement in 20 minutes, reducing downtime from 3 hours to 0.3 hours.

GE PT150 Pressure Transducer: GE’s mid-range pressure sensor. Outputs a 4-20 mA signal optimized for IS200BICLH1B’s 16-bit resolution—ensures pressure measurements with ±0.1% accuracy for semi-critical applications.

GE 9200 Flow Transmitter: GE’s industrial flow sensor. Transmits 4-20 mA flow data to IS200BICLH1B—ideal for auxiliary fuel, water, and lube oil flow monitoring in turbine systems.

IS200BICHH1A: GE’s high-precision current input module. Upgrade option for IS200BICLH1B when 18-bit resolution, redundant communication, or SIL 2 compliance is required for critical parameters (e.g., main steam pressure).

IS200BPIBG1A

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Power off the IS200CABPG1B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series B/C controllers. For wiring: Use shielded twisted-pair cables (20–22 AWG) for 4-20 mA/0-20 mA signals—ground the shield at both ends for 4-wire sensors and single-end at the module for 2-wire sensors (to avoid ground loops). Connect 2-wire sensors to the module’s excitation terminals (“EX+”/”EX-“)—ensure total excitation current does not exceed 150 mA. Torque terminal screws to 0.7–0.9 N·m to resist turbine vibration. Label each channel with sensor ID, signal type, and full-scale range (e.g., “Aux Feedwater Flow #3 – 4-20 mA = 0-200 t/h”).

Commissioning Steps: After installation, use GE’s ToolboxST software to configure each channel: set input range (4-20 mA/0-20 mA), filter cutoff (5-50 Hz), and notch filter (50/60 Hz). Perform a loop test with a precision current calibrator (e.g., Fluke 787): inject 4 mA (0%), 12 mA (50%), and 20 mA (100%) signals, and verify the module’s digital output matches ±0.08% of full scale. Enable Modbus RTU communication via the RS-485 port and confirm data transmission to the plant’s SCADA system. Set up alarm thresholds (e.g., 21 mA for over-range, 3.9 mA for under-range) to trigger alerts for sensor faults.

Maintenance Suggestions: Inspect IS200BICLH1B’s status LEDs daily—green = normal, amber = signal drift, red = module fault. Calibrate channels annually using a NIST-traceable current source: adjust offset and gain via ToolboxST if deviation exceeds ±0.15% of full scale. Clean backplane connectors quarterly with compressed air (30 PSI max) to remove dust and prevent communication errors. Check excitation voltage monthly (should be 24 ±0.5 V DC) to ensure 2-wire sensors receive stable power. If a channel fails, use the module’s self-test function to isolate the issue (sensor vs. module): replace the module only if the self-test fails, and use only GE-certified spares to maintain isolation ratings and compatibility.

Service and Guarantee Commitment

IS200BICLH1B comes with a 3-year standard warranty from GE, covering defects in materials (e.g., ADC circuits, excitation regulators) and workmanship. For failures within warranty (e.g., accuracy drift >±0.15%, communication loss, excitation voltage failure), GE ships a replacement within 24 hours from regional hubs (Houston, Singapore, Frankfurt) and provides free remote commissioning support to minimize downtime.

GE offers 24/7 global technical support for IS200BICLH1B: Certified Mark VIe engineers specialize in current-loop calibration, noise suppression optimization, and Modbus RTU setup. Support is available via phone, email, or remote desktop—engineers can remotely adjust filter settings, troubleshoot signal drift, and validate communication with SCADA systems. Customers gain access to IS200BICLH1B’s calibration manuals, EMC test reports, and compatibility matrices.

For semi-critical applications (e.g., combined-cycle auxiliary systems, industrial turbines), GE provides extended warranty options (up to 5 years) that include annual on-site calibration and preventive maintenance. These services ensure the module maintains ±0.08% accuracy and complies with industry safety standards, providing long-term reliability for turbine control systems.

If you’re upgrading mid-range current input modules for semi-critical parameter monitoring or designing a balanced-cost Mark VIe system, contact us for a customized IS200BICLH1B solution. Our team will map your sensor network to the module’s channels, optimize filter settings for your environment, and design a power/communication setup to maximize uptime and cost efficiency.