Description

Key Technical Specifications

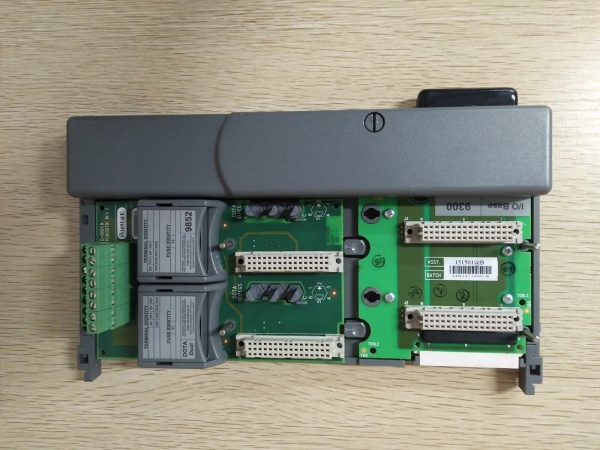

| Parameter | Details |

|---|---|

| Manufacturer | ICS Triplex (affiliated to Rockwell Automation) |

| Electrical Parameters | There are differences in power supply parameters in different application scenarios. It can support 220V AC input, and some supporting systems can adapt to 24VDC power supply and even 100 – 240V AC input. The 2500V shock-resistant optoelectronic isolation barrier design eliminates the need for external fuses and improves the anti-interference ability of the module. |

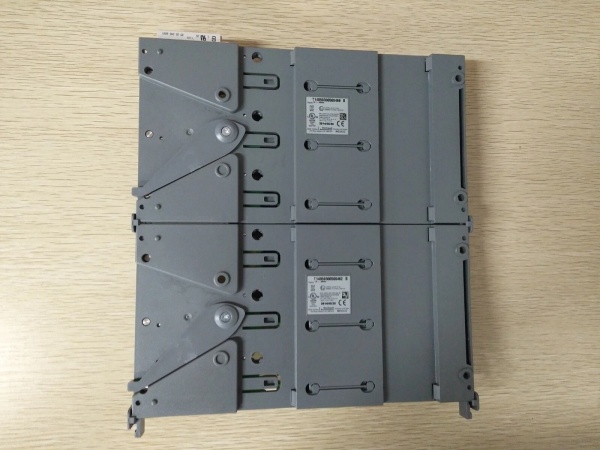

| Physical Indicators | The size data of different versions varies slightly. The common size is 17.5cm×15.4cm×8.6cm, and there is also a version with dimensions of 3.1cm×30.5cm×26.5cm. The weight is about 1.2 – 1.28kg, and it supports panel installation, which is convenient for integration into control cabinets. |

| Environmental Adaptability | It has strong environmental adaptability, and the operating temperature range can reach -40°C to 70°C. It can work stably in harsh industrial environments with large temperature differences, and can adapt to the common humidity conditions of industrial sites. |

| Safety & Compliance | It has obtained CE and UL certifications, which meet the relevant safety standards of the industry. The design of its isolation barrier and the matching TMR architecture system can ensure the reliability of signal acquisition and transmission in critical scenarios. |

ICS Triplex T9831

Field Application & Problem Solved

The T9831 can effectively solve such problems. For example, in an onshore oilfield’s oil extraction process control system, this module is responsible for collecting analog signals such as oil pressure and flow from multiple downhole sensors. Its 16-channel design can meet the simultaneous collection needs of multiple groups of sensors. The automatic diagnosis function can timely detect the line fault between the sensor and the module, and the staff can quickly troubleshoot, avoiding production suspension caused by delayed fault handling. In a chemical plant’s reactor temperature monitoring system, the module’s shock-resistant isolation barrier can resist the electromagnetic interference generated by surrounding chemical reaction equipment, ensuring that the collected temperature analog signals are accurate, and providing a reliable basis for the system to adjust the reactor’s heating power.

ICS Triplex T9831

Installation & Maintenance Pitfalls (Expert Tips)

- Ignoring Hot-Swapping Operation Specifications: Although the module supports hot-swapping, random hot-swapping during the peak operation of the system may cause instantaneous signal interruption. It is necessary to perform hot-swapping operations when the system is in a low-load or standby state, and follow the operation steps in the manual.

- Neglecting Installation Environment: Although the module has a wide operating temperature range, installing it in an area close to high-temperature equipment such as boilers for a long time will still affect its service life. It should be installed away from high-temperature and high-corrosion sources as much as possible.

- Incorrect Isolation Configuration: The module has a built-in optoelectronic isolation barrier. If external isolation devices are added blindly during installation, signal conflicts will be caused. It is necessary to confirm the system configuration in advance and avoid redundant isolation settings.

- Overlooking Regular Self-Test: The module’s automatic diagnosis function needs to be matched with regular manual self-test. If only relying on the system’s automatic prompt, potential hidden dangers such as weak channel contact may be missed. It is recommended to conduct a comprehensive function test on the module every 3 – 6 months.