Description

Key Technical Specifications

- Redundancy and Fault Tolerance: The TMR architecture equips each I/O point with three independent channels. Even if one channel fails, the other two can maintain normal operation, avoiding data loss or system downtime caused by single-point faults. It also has built-in comprehensive diagnostic tools that can quickly isolate and locate faults, laying a foundation for proactive maintenance and reducing the risk of sudden failures.

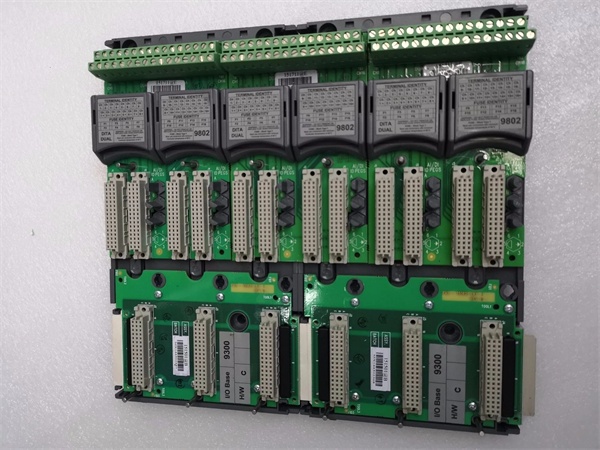

- Expansion and Connection Performance: It is designed with 24 slots that can be compatible with various types of I/O modules in the Aadvance series. It supports two I/O buses. Bus 1 can be directly connected to the processor unit, and Bus 2 can be expanded through an expansion cable. Each bus can be extended up to 8 meters. In addition, it can be seamlessly connected to the T9100 processor base unit and other T9300 I/O base units, and can also use the T9310 expansion cable to connect more I/O base units to meet the expansion needs of large – scale control systems.

- Installation and Operation Advantages: It adopts top and bottom clip fixing, which can be stably installed in the control system. The unused connectors are protected by black plastic covers to prevent dust and damage. Its low-power design reduces the overall energy consumption of the system. At the same time, the drag – and – drop programming development environment makes the system configuration more intuitive and efficient, shortening the deployment cycle.

ICS Triplex T9300

Field Application & Problem Solved

- Oil and Gas Field Control System: In onshore and offshore oil and gas exploitation sites, there are a large number of sensors and actuators that need to be connected to the control system. The T9300 I/O backplane can centrally connect these I/O modules. Its TMR redundancy design ensures that even in harsh marine or field environments with strong electromagnetic interference, the signal transmission between the modules and the processor unit is not interrupted. This solves the problem of unstable signal transmission in traditional backplanes, thus ensuring the normal operation of oil and gas extraction and transportation processes.

- Thermal Power Plant Safety Monitoring System: Thermal power plants involve multiple links such as boiler combustion and steam transmission, and need to monitor a large number of temperature, pressure and other parameters. The T9300 can connect various analog and digital I/O modules corresponding to these parameters. Its 24 – slot design and expansion capability can meet the needs of multi – parameter monitoring. The SIL 3 certification ensures that it can reliably transmit fault signals when abnormal parameters occur, triggering protective measures in time and avoiding safety accidents such as boiler explosions.

Installation & Maintenance Pitfalls (Expert Tips)

- Standardized Connection Operation: When connecting the two I/O buses, clearly distinguish Bus 1 (connected to the processor unit) and Bus 2 (expanded by cable). Do not mix up the connection ports. At the same time, ensure that the length of the expansion cable does not exceed 8 meters, otherwise, it will lead to signal attenuation and affect the normal communication of the system.

- Module Installation Precautions: When inserting I/O modules into the 24 slots, make sure that each module is firmly inserted in place. After installation, use the top and bottom clips to fix the base unit. Avoid loose installation caused by vibration in the industrial site, which may lead to poor contact between the module and the backplane. In addition, protect the unused connectors with plastic covers to prevent dust accumulation from causing short circuits.

- Regular Diagnostic Maintenance: Regularly use the built-in diagnostic tools to check the working status of each channel and bus. Record the diagnostic results to track potential fault trends. At the same time, back up the system configuration parameters regularly. When the backplane needs to be replaced, it can quickly restore the system function and reduce downtime.