Description

Key Technical Specifications

| Parameter | Details |

|---|---|

| Manufacturer | ICS Triplex (integrated into Schneider Electric’s Triconex brand) |

| Electrical Parameters | The operating voltage is 24VDC, and the maximum current consumption is no more than 100mA. It supports multiple voltage ranges such as ±10V, 0 – 10V and multiple current ranges such as 0 – 20mA, 4 – 20mA. The data update rate is 3.60ms for single-ended inputs and 1.80ms for differential inputs. |

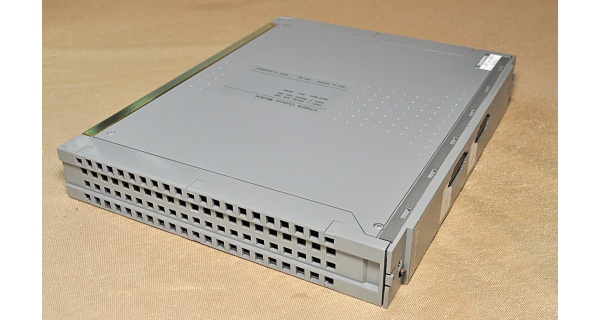

| Physical Indicators | The weight is about 1.4kg, and one common size is 320mm × 32.26mm × 257mm. The heat dissipation capacity is 9 watts per hour, which can avoid performance degradation caused by overheating during long-term operation. |

| Environmental Adaptability | The operating temperature range is 0°C – 60°C, and the storage temperature is -40°C – 85°C. It can work normally under 0% – 95% non-condensing humidity, which is adaptable to most harsh industrial environments. |

| Safety & Compliance | It meets the IEC 61508 SIL 3 safety standard. With 2500V isolation between field wiring and control logic, it can effectively resist electromagnetic interference and ensure the safety and stability of signal transmission. It also has relevant industry safety certifications to meet the requirements of critical industrial scenarios. |

ICS Triplex T3420A

Field Application & Problem Solved

For example, in an offshore oil platform’s wellhead pressure control system, this module is responsible for collecting analog signals from multiple wellhead pressure transmitters. Its multi-range input design can match different types of pressure transmitters, and the 2500V high isolation performance resists electromagnetic interference from marine equipment and harsh weather, ensuring the accuracy of pressure data. In a thermal power plant’s steam turbine control system, it collects temperature and pressure signals of the steam turbine. With the HART protocol, it realizes two-way communication between the module and the main control system. The self-diagnostic function can promptly detect signal line faults, which is convenient for maintenance personnel to troubleshoot and avoid shutdowns caused by delayed handling of abnormal signals.

ICS Triplex T3420A

Installation & Maintenance Pitfalls (Expert Tips)

- Improper Jumper Selection: The module can switch between 16 single-ended and 8 differential inputs via jumpers. If the jumper position is wrong during installation and does not match the type of connected field signal, signal distortion or acquisition failure will occur. It is necessary to confirm the signal type in advance and set the jumper correctly.

- Neglecting Protocol Compatibility Check: Although it supports the HART protocol, if the communication protocol of the connected main control system is not adjusted and matched during installation, data transmission interruption may occur. It is necessary to complete protocol parameter configuration before integration.

- Ignoring Heat Dissipation Space: The module has a heat dissipation capacity of 9 watts per hour. If it is installed too densely with other high-heat modules in the control cabinet, heat accumulation will affect its measurement accuracy. It is necessary to reserve a certain heat dissipation gap during installation.

- Overlooking Regular Calibration: Although the module has high accuracy, its accuracy will drift at a rate of 55 ppm/°C under the 0 – 10V range during long-term use. Failure to calibrate regularly will lead to deviation in collected data. It is recommended to conduct accuracy calibration every 6 – 12 months according to the usage environment.