Description

Key Technical Specifications

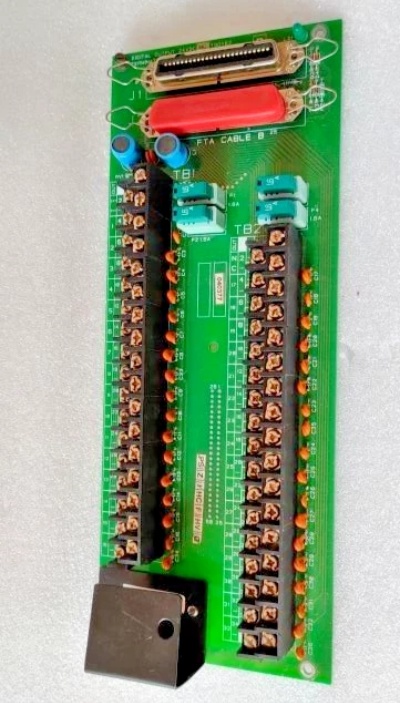

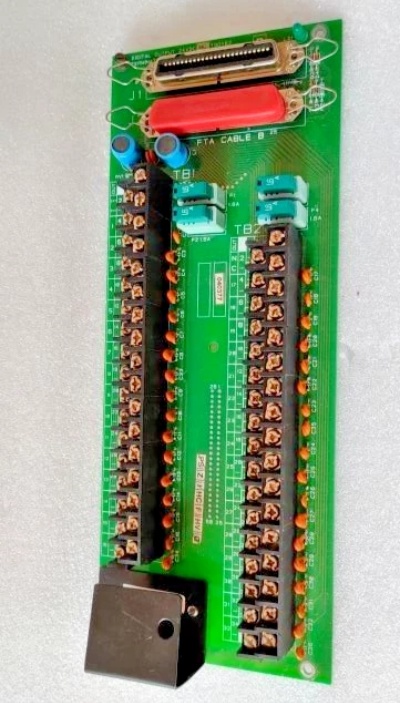

- Model Number: MU-TDOD12

- Manufacturer: Honeywell Process Solutions

- Output Channels: 16 independent discrete digital outputs

- Output Voltage: 24VDC nominal (20–30VDC operating range)

- Output Current Rating: 0.5A continuous per channel; 1A peak (1 second max)

- Isolation Rating: 500V AC channel-to-channel; 1500V AC channel-to-backplane

- Status Indicators: Per-channel red LED (illuminates when output is energized)

- Power Supply: Powered via TDC 3000 I/O rack backplane (no external power required)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Mounting Type: Rack-mounted (fits TDC 3000 I/O chassis)

- Diagnostic Capabilities: Output short-circuit detection, backplane communication fault monitoring

- Certifications: UL 508, CSA C22.2 No. 142, CE compliant

Honeywell MC-TDOY62

Field Application & Problem Solved

In refineries, chemical plants, and pulp mills still running legacy TDC 3000 systems, the biggest pain point with digital output modules is density and reliability. Older DO modules only offered 8 channels per slot, wasting valuable rack space in already crowded control cabinets. They also lacked robust isolation, so a shorted solenoid valve in one loop would take down the entire module, triggering unplanned process shutdowns. The MU-TDOD12 solves both issues with 16 channels per slot and 500V channel-to-channel isolation, maximizing rack utilization and preventing cross-channel faults.

You’ll typically find this module in TDC 3000 I/O racks controlling critical 24VDC field devices: actuating solenoid valves on raw material feed lines, triggering contactors for pump motors, and powering status lights on control panels. It’s a go-to replacement for obsolete 8-channel modules because it drops directly into existing slots without rewiring or controller reconfiguration— a lifesaver for plants that can’t afford downtime for system overhauls. Its core value is density paired with ruggedness: 16 channels mean fewer modules per rack, reducing wiring complexity and failure points, while the isolation ensures a single field fault doesn’t cascade into a system-wide issue.

Another hidden value is its built-in short-circuit protection. In corrosive environments, solenoid valve wiring often frays and shorts to ground; the MU-TDOD12 detects this and shuts down the affected channel without impacting others. I’ve seen a refinery reduce DO module replacements by 60% after switching to this module— a direct result of its isolation and short-circuit protection features. For maintenance teams stuck with legacy TDC 3000 systems, this module is a reliable workhorse that extends the life of aging control infrastructure.

Installation & Maintenance Pitfalls (Expert Tips)

Channel Load Limits Are Non-Negotiable: Rookies often connect 1A solenoid valves to this module, assuming the 0.5A continuous rating is a “suggestion.” It’s not— exceeding the continuous current rating will melt the module’s internal relays over time, leading to intermittent output failures that are impossible to trace. Always check the field device’s current draw before wiring; if it exceeds 0.5A, add an external relay to handle the load. I’ve fixed three melted modules in a single quarter because a tech skipped this step.

LED Indicators Are Your First Diagnostic Tool: The red per-channel LEDs aren’t just for show— they confirm whether the module is sending an output signal to the field. If the HMI says an output is energized but the LED is off, the problem is in the controller or backplane communication. If the LED is on but the field device doesn’t actuate, the issue is in the wiring or the device itself. Too many techs skip checking the LEDs and waste hours troubleshooting the controller when the problem is a loose terminal block. Make this a first-step check in your diagnostic process.

Backplane Seating Must Be Perfect: This module connects to the TDC 3000 rack via a backplane connector, and rookies often don’t seat it fully— they push until it “feels” right, not until it clicks into place. A loose connection causes intermittent communication faults: the module will drop off the network randomly, triggering false output faults and process alarms. To seat it correctly, align the connector with the backplane slot, push firmly until you hear a click, then tug gently to confirm it’s locked. Don’t use a screwdriver to pry it into place— this bends the connector pins and ruins the module.

Don’t Ignore Short-Circuit Alerts: The module’s short-circuit detection is a safety feature, not a nuisance. When it trips a channel due to a short, it’s telling you there’s a frayed wire or faulty solenoid in the field. Ignoring the alert and forcing the channel back on will burn out the module’s internal relay and could cause a fire hazard in the field. Always trace the wiring to find the short— in corrosive environments, this is usually a frayed cable or corroded terminal. Fix the root cause, don’t just reset the alert.

Honeywell MC-TDOY62

Technical Deep Dive & Overview

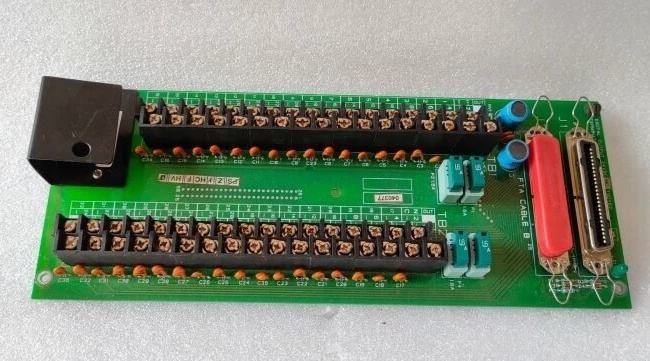

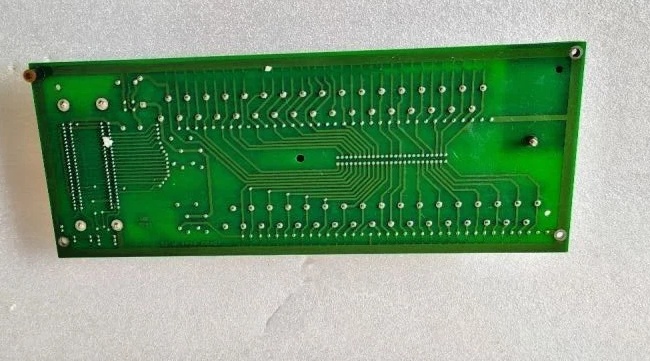

The MU-TDOD12 is a high-density digital output module designed exclusively for Honeywell’s legacy TDC 3000 distributed control system, optimized for reliability in harsh industrial environments. At its core, each of the 16 channels uses a sealed electromechanical relay paired with an optocoupler for isolation— the optocoupler separates the low-voltage logic signal from the 24VDC field voltage, while the relay provides a robust switch for field device power. The 500V channel-to-channel isolation is critical: it ensures a shorted solenoid in one loop doesn’t damage the module or disrupt other channels, a common failure mode in non-isolated modules.

The module draws all its power from the TDC 3000 I/O rack backplane, eliminating the need for external power wiring and reducing installation time. Its per-channel LEDs are hardwired directly to the relay contacts, so they provide real-time output status that’s independent of controller communication— a critical tool when the network is down or the controller is faulty. The built-in short-circuit protection works by monitoring current draw on each channel; if it exceeds 1A for more than 1 second, the module shuts down the channel and triggers a fault signal to the controller.

Unlike modern smart modules, the MU-TDOD12 has no on-board firmware or programming requirements— it’s a “plug-and-play” device that’s recognized automatically by the TDC 3000 controller. This is a feature for legacy systems: it means there’s nothing to configure, update, or misprogram, reducing the risk of human error during installation. Its compact design fits into standard TDC 3000 I/O rack slots, and the 16-channel density cuts down on the number of modules needed per rack. In the field, this module’s strength is its simplicity and durability— it’s built to withstand the vibration, temperature swings, and corrosion that plague industrial environments, and it runs for 10+ years without unplanned failures. For plants stuck with TDC 3000 systems, it’s an indispensable component that keeps legacy processes running smoothly.