Description

-

- Core Technical Performance

- Output & Isolation Performance: It has 32 isolated digital output channels, each with a maximum load current of 500mA, which can stably drive multiple common industrial on-site execution components. The module achieves 500Vrms isolation between channels and 1000Vrms isolation between channels and the ground. This isolation design effectively reduces signal interference between channels and ensures the accuracy of digital output signals in complex industrial electromagnetic environments.

- Power Supply & Compatibility: It adopts 24V DC power supply from the IOP rack, with a voltage tolerance of ±10%, which is in line with the power supply standards of most industrial control systems. In terms of compatibility, it can be perfectly matched with MU/MC-P DOY22 processors, and can be seamlessly integrated into Honeywell TDC 3000 DCS to ensure smooth data interaction and control command transmission.

- Environmental Adaptability: The module has excellent environmental resistance. It can work stably in the temperature range of -40°C to +70°C, and can adapt to the humidity environment of 5% – 95% non-condensing. In addition, its conformal coating can prevent moisture, dust and corrosion, which enables it to maintain reliable operation in harsh industrial sites with more dust and large temperature changes.

Honeywell MC-TDOY62

- Physical & Installation Characteristics

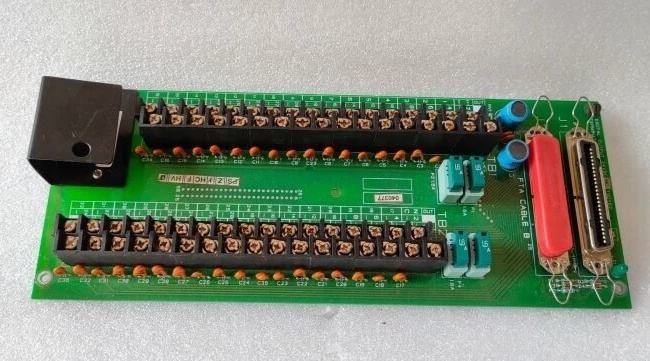

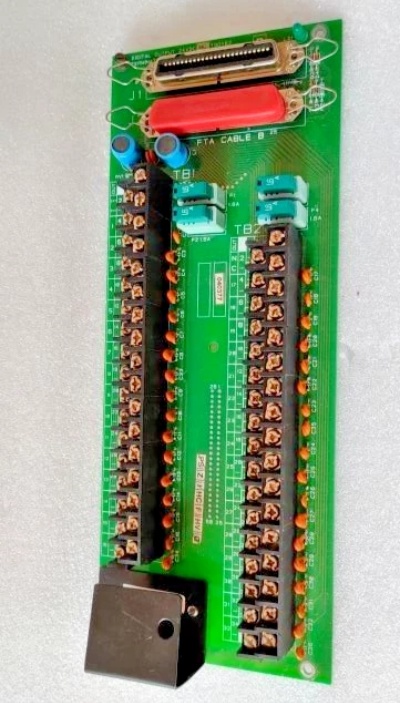

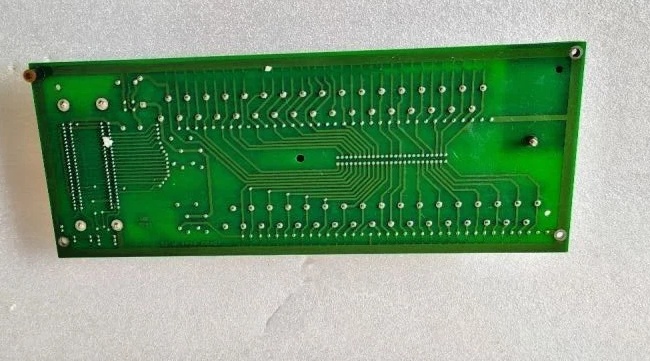

The module adopts a rack-mounted or DIN rail installation method, which is convenient for assembly and disassembly in the control cabinet. It uses screw-type terminals for wiring, which can ensure the firmness of cable connection and reduce signal transmission problems caused by loose wiring. Its overall size is about 30.7cm × 12.4cm × 5.3cm, and its weight is about 2.0kg. The compact structure helps save the installation space of the control cabinet.

- Typical Application Scenarios

This module is widely used in process automation fields such as oil, gas, chemical industry and power generation. In petrochemical production workshops, it can output digital control signals to control the opening and closing of solenoid valves on reaction kettles and storage tanks, so as to realize the precise control of material input and output. In thermal power plants, it can be connected with contactors of auxiliary equipment such as coal feeding and ash removal, and control the start and stop of the equipment through digital signals. In addition, it can also be applied to the control of automation equipment in manufacturing lines, providing stable digital output support for the operation of the production line.

Honeywell MC-TDOY62

- Core Technical Performance

-

Installation & Maintenance Notes

- Confirm Compatibility with Processors: The module is specially matched with MU/MC-P DOY22 processors. Before installation, it is necessary to confirm whether the processor model of the current DCS is consistent. Mismatched models will lead to communication failures and failure to realize output control functions. It is recommended to verify the compatibility through the system manual or official technical data.

- Ensure Standardized Wiring Operation: It adopts screw-type terminals for wiring. When connecting cables, it is necessary to select wires that meet the current requirements, and use professional tools to fasten the screws to avoid poor contact caused by loose wiring. After wiring, check the continuity of each channel to prevent open circuit or short circuit, which will affect the normal output of signals.

- Pay Attention to Environmental Protection: Although the module has conformal coating protection, it should avoid direct contact with corrosive gases and liquids during installation. It is recommended to install it in a control cabinet with dustproof and waterproof functions. For working environments with large temperature fluctuations, pay attention to the heat dissipation of the control cabinet to prevent the module from being affected by extreme temperatures for a long time.

- Regularly Inspect Channel Status: During daily maintenance, check whether the output signal of each channel is normal. For channels that control key equipment, it can be matched with a multimeter to test the output current to ensure that it is within the 0.5A standard range. At the same time, check whether the conformal coating on the surface of the module is intact. If there is peeling or damage, timely maintenance or replacement should be carried out to avoid internal circuit failure.