Description

Detailed parameter table

| Parameter name | Parameter value |

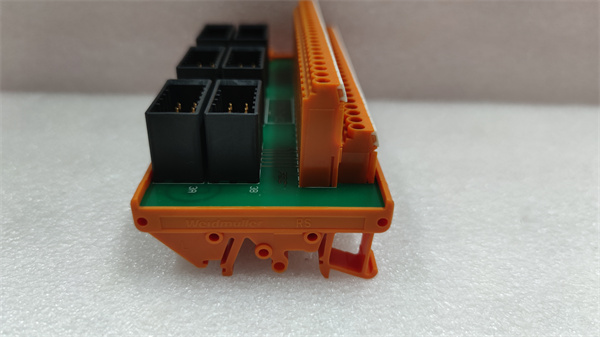

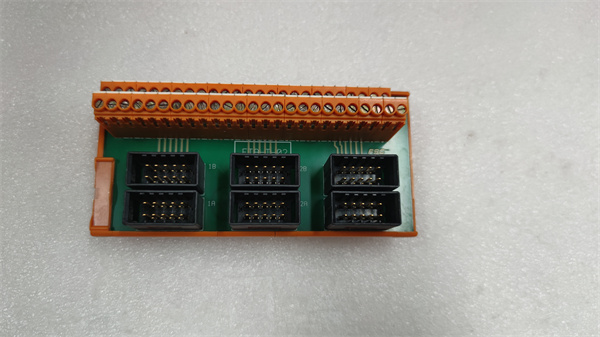

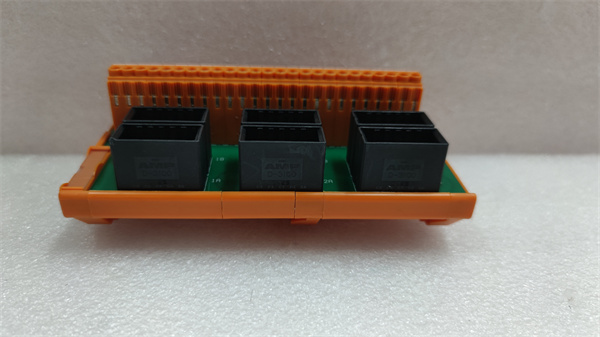

| Product model | FC-PUIO01 |

| Manufacturer | Honeywell |

| Product category | Universal process I/O module |

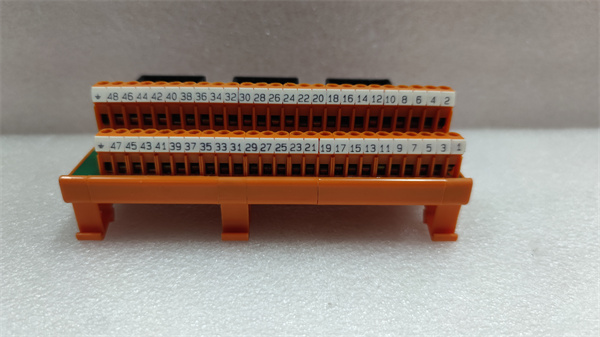

| Number of channels | 16 (8 analog inputs, 4 analog outputs, 4 digital I/O) |

| Analog input type | 4-20 mA, 0-10 V DC, RTD, thermocouple (configurable) |

| Analog output type | 4-20 mA, 0-10 V DC (configurable) |

| Digital I/O type | 24 V DC (PNP/NPN configurable, 2 inputs + 2 outputs) |

| Accuracy | Analog: ±0.05% of full scale; Digital: ±1% |

| Response time | Analog: ≤50 ms; Digital: ≤1 ms |

| Isolation rating | 2.5 kV AC (channel to channel, channel to backplane) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 15 W |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 145 mm x 105 mm x 85 mm (5.71 in x 4.13 in x 3.35 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell FC-SCNT01, FC-RPB2N12, Experion PKS |

| Mounting type | DIN rail mounting (35 mm) with backplane connectivity |

| Certification | IEC 61131-2, CE, UL 508, ATEX |

Honeywell FTA-T-02

Product introduction

The FC-PUIO01 is a versatile universal process I/O module from Honeywell, engineered to serve as a flexible interface between field devices and industrial control systems. As a key component of Honeywell’s process automation portfolio, this module integrates analog and digital I/O capabilities in a compact design, enabling seamless data acquisition and control for a wide range of industrial processes.

FC-PUIO01 is designed to bridge diverse field devices—from temperature sensors and pressure transmitters to solenoid valves and limit switches—with control systems like Honeywell’s FC-SCNT01 safety controller and FC-RPB2N12 field controller. Its configurable channels eliminate the need for multiple specialized modules, simplifying system architecture in industries such as chemical processing, food and beverage, and water treatment. Whether deployed in standard process control loops or integrated with safety systems for non-safety-critical monitoring, FC-PUIO01 delivers reliable performance, adaptability, and ease of integration—making it a cornerstone of efficient industrial automation.

Core advantages and technical highlights

Universal I/O versatility: FC-PUIO01 combines 8 analog inputs, 4 analog outputs, and 4 digital I/O (2 inputs + 2 outputs) in a single module, with each channel configurable to support multiple signal types. Analog inputs can be programmed for 4-20 mA, 0-10 V DC, RTDs (Pt100), or thermocouples (J/K/T types), while analog outputs support 4-20 mA or 0-10 V DC. Digital channels are configurable as PNP or NPN, accommodating diverse sensors and actuators. This flexibility reduces inventory complexity and allows quick reconfiguration during plant upgrades or process changes.

High accuracy and responsiveness: With ±0.05% accuracy for analog signals, FC-PUIO01 ensures precise measurement and control—critical for applications like pharmaceutical batch processing, where tight parameter control (e.g., temperature ±0.1°C) is required. Analog channels feature low noise filtering to maintain signal integrity in electrically noisy environments, while digital channels offer ≤1 ms response time for fast-acting devices like emergency stop relays.

Robust isolation: Each channel provides 2.5 kV AC isolation from other channels and the backplane, preventing ground loops and protecting control systems from voltage transients. This isolation is particularly valuable in distributed installations with long cable runs, such as water treatment plants, where electrical interference from pumps or motors could corrupt signals. Isolation also ensures a fault in one channel (e.g., a shorted pressure transmitter) does not affect others, maintaining system availability.

Seamless system integration: FC-PUIO01 integrates seamlessly with Honeywell’s FC-SCNT01 safety controller for non-safety process monitoring and with FC-RPB2N12 for standard control loops. It communicates via backplane with Experion PKS, enabling centralized data logging, trending, and HMI visualization. This interoperability simplifies system design, allowing engineers to mix and match I/O types while maintaining a unified control architecture.

Typical application scenarios

In chemical processing plants, FC-PUIO01 monitors and controls batch reactor systems. Its analog inputs connect to Pt100 RTDs (temperature), 4-20 mA pressure transmitters, and pH sensors (0-10 V), while analog outputs control variable speed drives (4-20 mA) for agitators and dosing pumps. Digital inputs track valve position switches, and digital outputs actuate solenoid valves for sample collection. Integration with FC-RPB2N12 allows the module to share data with the process control system, enabling automated recipe execution and quality control.

Food and beverage facilities utilize FC-PUIO01 in pasteurization lines, where it monitors thermocouple temperatures (J-type) of heated product and controls steam valves via 4-20 mA outputs to maintain precise temperature profiles. Digital inputs detect conveyor jam sensors, triggering digital outputs to stop the line if a fault occurs. The module’s wide operating temperature range (-40°C to +70°C) ensures reliability in both cold storage areas and near steam-heated equipment.

Water treatment plants deploy FC-PUIO01 to manage filtration and chemical dosing systems. Analog inputs measure turbidity (4-20 mA) and pH (0-10 V) of treated water, while analog outputs control chemical metering pumps (4-20 mA). Digital I/O monitors filter pressure switches and actuates backwash valves, ensuring optimal filter performance. Isolation between channels prevents interference from variable frequency drives used in pump systems, maintaining measurement accuracy.

Honeywell FTA-T-02

Related model recommendations

FC-SCNT01: Safety controller that pairs with FC-PUIO01 for non-safety process monitoring, enabling data sharing between process control and safety systems.

FC-RPB2N12: Field controller that integrates FC-PUIO01 into standard control loops, supporting complex logic and sequence control for industrial processes.

FC-PS24-3A: 24 V DC power supply optimized for FC-PUIO01, providing stable power with overload protection to support the module’s 15 W consumption.

Experion PKS SCADA: Honeywell’s distributed control system that visualizes data from FC-PUIO01, enabling operators to monitor trends, set alarms, and adjust setpoints.

TC-100 Thermocouple Extension Cable: Shielded cable for connecting thermocouples to FC-PUIO01, minimizing signal loss and electromagnetic interference.

Installation, commissioning and maintenance instructions

Installation preparation: Mount FC-PUIO01 on a 35 mm DIN rail in a dust-free enclosure with ambient temperature between -40°C and +70°C. Ensure the backplane is securely connected to the control system and redundant power supplies (24 V DC, fused at 1.5A). Use shielded twisted-pair cables for analog signals (0.5 mm²) and digital signals (0.75 mm²), grounding shields at the module end to reduce noise. Label each channel with the connected device and signal type (e.g., “T1 – Reactor Temp (Pt100)”) for easy troubleshooting.

Commissioning: Configure channel types using Honeywell’s configuration software, setting analog ranges, RTD/thermocouple types, and digital polarities. Calibrate analog inputs with a certified signal generator (e.g., 4 mA = 0°C, 20 mA = 100°C) and verify outputs with a multimeter. Test digital channels by simulating inputs (e.g., closing a switch) and checking for corresponding output activation. Validate communication with the control system by monitoring real-time data in Experion PKS, ensuring values match field device readings.

Maintenance suggestions: Perform monthly visual inspections to check for loose connections or corrosion on terminals. Calibrate analog channels quarterly using a certified standard to maintain ±0.05% accuracy—critical for regulated industries like pharmaceuticals. Use diagnostic software to run annual channel tests, checking for drift, noise, or isolation degradation. Replace the module if digital response time exceeds 1 ms or analog accuracy deviates beyond specifications. Back up configuration settings to a secure device, and use only Honeywell-certified spares to ensure compatibility.

Service and guarantee commitment

FC-PUIO01 is backed by Honeywell’s 3-year warranty, covering manufacturing defects and ensuring compliance with published performance specifications under normal operating conditions. Honeywell’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and integration, with a 12-hour response time for critical issues.

We offer on-site commissioning services, including channel configuration, calibration, and integration with control systems, performed by certified automation engineers. Extended warranty options (up to 5 years) include annual preventive maintenance, firmware updates, and priority technical support. In the event of a fault, Honeywell maintains regional stock of FC-PUIO01 modules, enabling next-day delivery to minimize downtime. All repairs use genuine components, ensuring the module retains its original accuracy, isolation ratings, and compatibility. This commitment reflects Honeywell’s dedication to industrial efficiency and customer operational reliability.