Description

Detailed parameter table

| Parameter name | Parameter value |

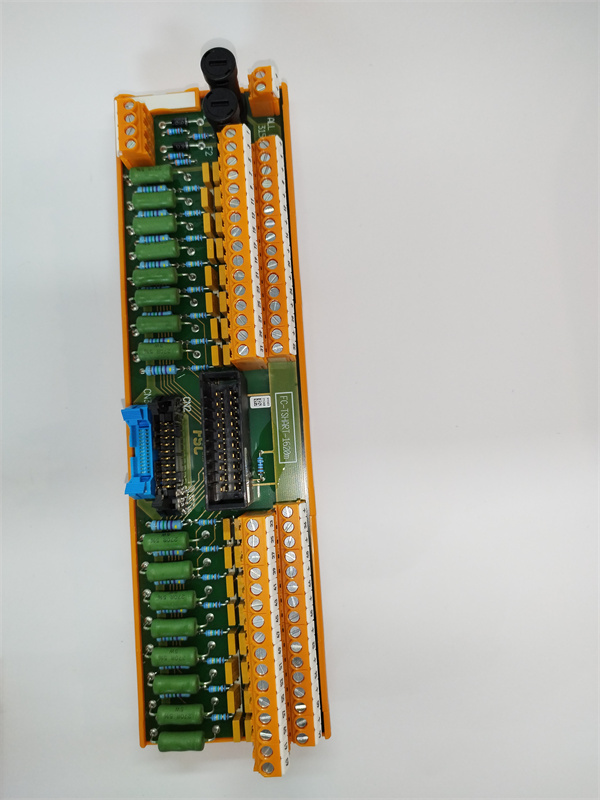

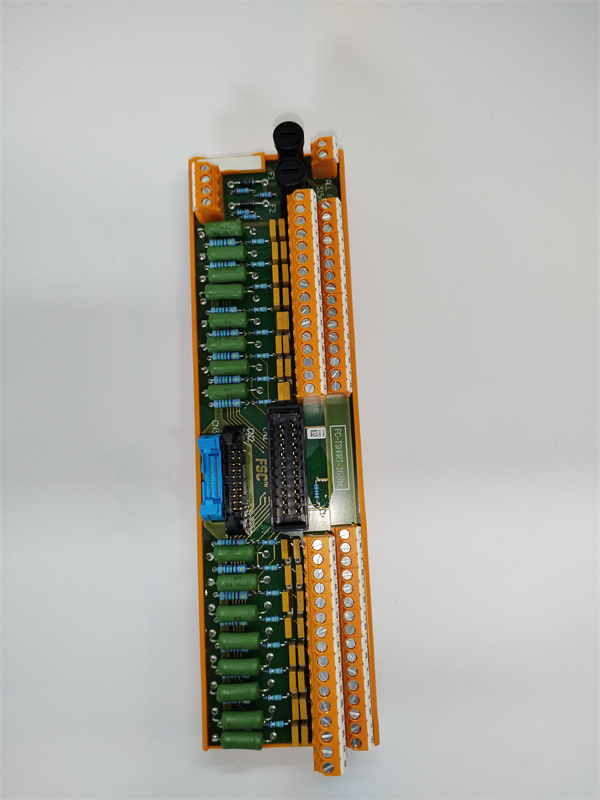

| Product model | FC-TSHART-1620M |

| Manufacturer | Honeywell |

| Product category | HART analog input module |

| Number of channels | 16 (isolated) |

| Input signal type | 4-20 mA (HART 7 compatible) |

| Measurement range | 0-24 mA |

| Accuracy | ±0.05% of full scale |

| Resolution | 16-bit |

| Update rate | 100 ms per channel (configurable) |

| Isolation rating | 2.5 kV AC (channel to channel, channel to backplane) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | Max 15 W |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 140 mm x 100 mm x 80 mm (5.51 in x 3.94 in x 3.15 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Experion PKS, Safety Manager |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61508 (SIL 2), CE, UL, ATEX, IECEx |

Honeywell FC-TSHART-1620M

Product introduction

The FC-TSHART-1620M is a high-performance HART analog input module from Honeywell, designed to serve as a critical interface between smart field devices and industrial control systems. As a key component of Honeywell’s distributed I/O ecosystem, this module excels in capturing and processing 4-20 mA signals with embedded HART 7 communication, enabling seamless integration with intelligent sensors, transmitters, and actuators.

FC-TSHART-1620M stands out for its ability to handle both analog measurement data and digital HART commands simultaneously, making it ideal for applications requiring deep device diagnostics alongside real-time process monitoring. With 16 isolated channels, it provides accurate, high-resolution data to Honeywell’s Experion PKS and Safety Manager systems, supporting both standard automation and safety-critical loops (SIL 2 certified). Whether deployed in oil and gas refineries, chemical plants, or power generation facilities, FC-TSHART-1620M ensures reliable data acquisition, simplifies device management, and enhances process visibility—laying the foundation for efficient and informed decision-making.

Core advantages and technical highlights

Dual-mode HART support: FC-TSHART-1620M fully complies with HART 7, enabling bidirectional communication with smart field devices. This means it not only measures 4-20 mA process variables (e.g., pressure, temperature, flow) but also retrieves diagnostic data, device configurations, and calibration information via HART commands. For example, it can read a pressure transmitter’s sensor health status while monitoring line pressure, allowing predictive maintenance and reducing unplanned downtime. This dual functionality eliminates the need for separate HART modems, streamlining system architecture.

High accuracy and resolution: With 16-bit resolution and ±0.05% accuracy, FC-TSHART-1620M delivers precise measurements even for small signal variations—critical in applications like pharmaceutical batch processing, where tight control of temperature or pH is essential. The module’s low noise design ensures stable readings in electrically noisy environments, such as near large motors or variable frequency drives, maintaining data integrity across diverse industrial settings.

Robust isolation: FC-TSHART-1620M features 2.5 kV AC isolation between channels and from channels to the backplane, preventing ground loops and protecting sensitive control systems from voltage spikes. This isolation is particularly valuable in distributed installations with long cable runs, where electrical interference is common. Each channel operates independently, ensuring a fault in one channel does not affect others—a key requirement for maintaining process continuity in critical applications.

Wide environmental resilience: Engineered to operate in extreme temperatures (-40°C to +70°C), FC-TSHART-1620M thrives in harsh industrial environments, from arctic oil fields to desert power plants. Its rugged design resists vibration, humidity, and electromagnetic interference (EMI), ensuring reliable performance in conditions that would degrade less robust modules. This durability reduces maintenance needs and extends service life in challenging locations.

Typical application scenarios

In oil refineries, FC-TSHART-1620M monitors crude oil distillation columns by connecting to 16 HART-enabled pressure and temperature transmitters. It captures real-time pressure readings (4-20 mA) for process control while using HART to retrieve transmitter diagnostics, such as sensor drift or membrane contamination. This data is sent to Experion PKS, allowing operators to address potential issues before they cause process upsets. The module’s SIL 2 rating also enables it to participate in safety loops, triggering alarms if pressure exceeds critical thresholds.

Chemical processing plants utilize FC-TSHART-1620M to manage batch reactors, where it connects to pH, level, and flow transmitters. Its high accuracy ensures precise monitoring of reaction parameters, while HART communication allows remote calibration of transmitters without disrupting production. For example, a pH transmitter’s calibration can be adjusted via the module during a batch pause, reducing the need for manual intervention in hazardous areas. The module’s wide temperature range ensures reliable operation near reactor jackets, where ambient temperatures fluctuate significantly.

Power generation facilities deploy FC-TSHART-1620M in turbine control systems, monitoring steam pressure, exhaust temperature, and lubricating oil flow via smart transmitters. Its fast update rate (100 ms) provides the real-time data needed for turbine load adjustments, while HART diagnostics track transmitter health to prevent unexpected failures during peak demand. The module’s isolation protects against electrical noise from turbine generators, ensuring measurement stability even in high-EMI environments.

Honeywell FC-TSHART-1620M

Related model recommendations

FC-TSHART-820M: An 8-channel variant of FC-TSHART-1620M, ideal for smaller systems or applications with fewer analog points, such as pilot plants or skid-mounted equipment.

FC-TSAO-820M: HART analog output module that pairs with FC-TSHART-1620M, providing 8 channels for 4-20 mA control signals to valves and variable speed drives, enabling closed-loop control.

FC-QPP-0001: Honeywell’s safety controller that integrates with FC-TSHART-1620M to process safety-critical analog data, extending system capabilities to SIL 3 in high-risk applications.

STT250: Honeywell’s smart temperature transmitter, optimized for use with FC-TSHART-1620M, providing accurate RTD/thermocouple measurements with rich HART diagnostics.

FC-PS24-3A: 24 V DC power supply designed to support FC-TSHART-1620M and connected field devices, featuring redundancy for uninterrupted operation.

Experion PKS HMI: Operator interface software that visualizes data from FC-TSHART-1620M, displaying both process variables and HART diagnostic information in a user-friendly dashboard.

FC-TSDI-16: Digital input module that complements FC-TSHART-1620M, adding 16 digital channels for monitoring discrete devices (e.g., limit switches) in mixed-signal systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-TSHART-1620M, ensure the DIN rail is securely mounted in a climate-controlled or ruggedized enclosure, with ambient temperature within -40°C to +70°C. Use a torque wrench set to 1.0 Nm to fasten the module, ensuring a stable fit. Verify the 24 V DC power supply is isolated, regulated, and protected by a 2A fuse. Use shielded twisted-pair cables (minimum 0.5 mm²) for field connections, grounding the shield at both ends to minimize EMI. Route signal cables separately from power cables, and maintain at least 30 mm clearance around the module for ventilation.

Maintenance suggestions: For FC-TSHART-1620M, perform monthly checks of status LEDs to verify power, communication, and channel health. Use Honeywell’s configuration software quarterly to run HART diagnostic scans, checking for device faults, calibration drift, or communication errors. Calibrate the module annually using a certified 4-20 mA signal generator to maintain accuracy. Inspect cable connections quarterly for tightness and corrosion, reterminating if necessary. If a channel fails, isolate it via software and replace the module with a Honeywell-certified spare to maintain isolation and safety certifications. Back up configuration settings to a secure device to simplify replacement.

Service and guarantee commitment

FC-TSHART-1620M is backed by Honeywell’s 5-year warranty, covering manufacturing defects and ensuring compliance with published performance specifications, including SIL 2 certification. Honeywell’s global technical support team provides 24/7 assistance for configuration, HART integration, and troubleshooting, with critical issues addressed within 6 hours.

We offer on-site commissioning services, where certified engineers verify channel calibration, configure HART communication, and integrate the module with Experion PKS. Extended warranty options (up to 7 years) include annual preventive maintenance, firmware updates, and priority access to technical support. In the event of a fault, Honeywell maintains regional stock of FC-TSHART-1620M modules, enabling next-day delivery to minimize downtime. All repairs use genuine components, ensuring the module retains its original accuracy, isolation ratings, and safety certifications. This commitment reflects Honeywell’s confidence in the reliability of FC-TSHART-1620M and its dedication to supporting seamless industrial operations.