Description

Detailed parameter table

| Parameter name | Parameter value |

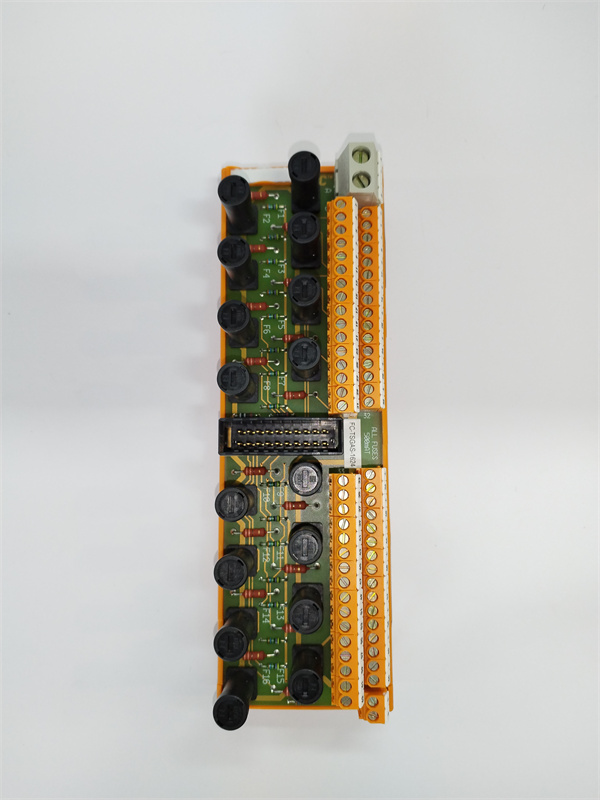

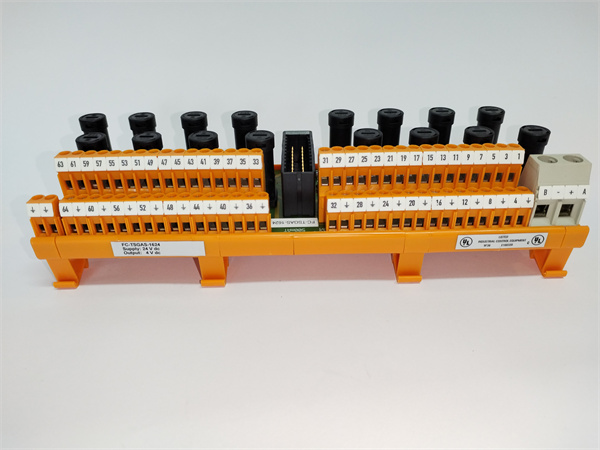

| Product model | FC-TSGAS-1624 |

| Manufacturer | Honeywell |

| Product category | Gas detection interface module |

| Number of channels | 16 (isolated) |

| Input signal type | 4-20 mA, HART 7 (for gas detectors) |

| Supported gas types | Toxic (e.g., H₂S, CO), combustible (e.g., CH₄) |

| Measurement range | 0-100% LEL (combustible), 0-100 ppm (toxic) |

| Accuracy | ±0.1% of full scale |

| Response time | ≤50 ms (signal processing) |

| Isolation rating | 3 kV AC (channel to channel, channel to backplane) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 20 W (including detector power) |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 150 mm x 110 mm x 90 mm (5.91 in x 4.33 in x 3.54 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Gas Detectors, Experion PKS, Safety Manager |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61508 (SIL 2), ATEX, IECEx, UL 61010 |

Honeywell FC-TSGAS-1624

Product introduction

The FC-TSGAS-1624 is a specialized gas detection interface module from Honeywell, engineered to serve as a critical link between gas detection sensors and industrial safety/control systems. As a core component of Honeywell’s gas monitoring ecosystem, this module is designed to process signals from 16 isolated channels of gas detectors, converting raw sensor data into actionable insights for both safety and process management.

FC-TSGAS-1624 excels in monitoring both toxic and combustible gases, leveraging HART 7 communication to not only capture 4-20 mA measurement signals but also retrieve diagnostic data from smart detectors. Its SIL 2 certification ensures it meets the rigor of safety-critical applications, enabling seamless integration with Honeywell’s Safety Manager for emergency shutdown (ESD) sequences, while compatibility with Experion PKS allows for centralized monitoring. Whether deployed in oil refineries, chemical plants, or wastewater treatment facilities, FC-TSGAS-1624 provides real-time gas concentration monitoring, predictive maintenance alerts, and rapid fault response—forming a vital safety barrier for personnel and assets.

Core advantages and technical highlights

Dual gas type support: FC-TSGAS-1624 is uniquely designed to handle both toxic and combustible gas detectors, eliminating the need for separate modules for different gas types. This versatility simplifies system design in facilities where multiple gas hazards exist—for example, a petrochemical plant monitoring both H₂S (toxic) and methane (combustible). The module automatically recognizes detector types via HART, configuring measurement ranges and alarm thresholds accordingly, reducing setup complexity.

Enhanced safety integrity: With SIL 2 certification per IEC 61508, FC-TSGAS-1624 ensures reliable performance in safety loops. It features built-in fault detection (e.g., open/short circuits, detector failures) and self-diagnostics with 99% coverage, triggering immediate alerts if a channel or the module itself malfunctions. This level of integrity is critical in applications like confined space monitoring, where a missed gas leak could lead to fatal exposures or explosions.

Advanced HART diagnostics: Beyond measuring gas concentrations, FC-TSGAS-1624 uses HART 7 to access detailed detector health data—such as sensor drift, filter contamination, or calibration due dates. For instance, it can identify a CO detector with a failing sensor element while still monitoring CO levels, enabling scheduled maintenance before a complete failure. This proactive approach reduces false alarms and ensures detectors remain reliable when needed most.

Robust isolation and ruggedness: The module’s 3 kV AC isolation exceeds industry standards, preventing ground loops and electrical interference that could corrupt gas measurements or trigger false alarms. This is particularly valuable in industrial environments with long cable runs from detectors to control rooms. Combined with its wide operating temperature range (-40°C to +70°C) and resistance to vibration/EMI, FC-TSGAS-1624 maintains performance in harsh conditions, from offshore platforms to desert pipelines.

Typical application scenarios

In oil and gas production facilities, FC-TSGAS-1624 monitors wellheads and processing areas by connecting to 16 Honeywell XNX gas detectors. It tracks methane (combustible) and H₂S (toxic) levels, with 4-20 mA signals converted to real-time concentrations displayed on Experion PKS. If methane exceeds 50% LEL or H₂S exceeds 10 ppm, the module triggers Safety Manager to activate ventilation systems and sound alarms via relay outputs. HART diagnostics also alert maintenance teams to replace detector sensors approaching end-of-life, preventing unplanned downtime.

Chemical manufacturing plants utilize FC-TSGAS-1624 in storage tank farms, where it monitors volatile organic compounds (VOCs) and toxic gases like chlorine. The module’s fast response time (<50 ms) ensures rapid detection of leaks during tank filling operations, enabling immediate shutdown of transfer pumps via Safety Manager. Its 3 kV isolation protects against electrical noise from nearby pumps, ensuring stable readings even in electrically noisy environments.

Wastewater treatment plants deploy FC-TSGAS-1624 to monitor biogas (methane) and hydrogen sulfide in digesters. The module connects to intrinsically safe detectors, processing signals to prevent explosive methane buildup and protect workers from H₂S exposure. HART data on detector calibration status is integrated into the plant’s CMMS, streamlining maintenance schedules. The module’s rugged design withstands the high humidity and corrosive fumes common in wastewater facilities, ensuring long-term reliability.

Honeywell FC-TSGAS-1624

Related model recommendations

FC-TSGAS-824: An 8-channel variant of FC-TSGAS-1624, ideal for smaller facilities or localized monitoring zones, such as laboratory fume hoods or small storage areas.

XNX Universal Transmitter: Honeywell’s smart gas detector, optimized for use with FC-TSGAS-1624, supporting multiple sensor types with advanced HART diagnostics.

FC-QPP-0001: Safety controller that pairs with FC-TSGAS-1624 to execute emergency shutdown sequences, extending safety capabilities to SIL 3 for high-risk areas.

RAE Systems QRAE 3: Portable gas detector that complements FC-TSGAS-1624 for spot checks, with data synced to Experion PKS for comprehensive gas monitoring.

FC-PS24-5A: Redundant 24 V DC power supply designed to support FC-TSGAS-1624 and connected detectors, ensuring uninterrupted operation during power fluctuations.

Safety Manager: Honeywell’s safety instrumented system that integrates with FC-TSGAS-1624 to manage gas-related ESD logic and alarm prioritization.

FC-TSDI-16: Digital input module that adds 16 discrete channels to FC-TSGAS-1624 systems, monitoring detector status indicators (e.g., fault LEDs) for enhanced diagnostics.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-TSGAS-1624, ensure the DIN rail is mounted in a dust-free, explosion-proof enclosure (if in hazardous areas) with ambient temperature between -40°C and +70°C. Use a torque wrench set to 1.2 Nm to secure the module. Verify the 24 V DC power supply is isolated, fused (3A), and capable of supplying 20 W (including detector power). Use shielded twisted-pair cables (minimum 0.75 mm²) for detector connections, grounding the shield at the module end to minimize EMI. Route cables separately from high-voltage lines, and label each channel with the corresponding detector location.

Maintenance suggestions: For FC-TSGAS-1624, perform weekly checks of status LEDs to verify power, communication, and channel health. Use Honeywell’s Gas Monitor Software monthly to run HART diagnostic scans, checking for sensor drift, filter blockages, or detector calibration due dates. Calibrate the module annually using a certified gas standard and signal generator to ensure accuracy. Inspect cable connections quarterly for corrosion or looseness, reterminating with stainless steel lugs if needed. If a channel fails, isolate it via software and replace the module with a Honeywell-certified spare to maintain SIL 2 integrity. Back up configuration settings to a secure device to simplify replacement.

Service and guarantee commitment

FC-TSGAS-1624 is backed by Honeywell’s 5-year warranty, covering manufacturing defects and ensuring compliance with SIL 2 and hazardous area certifications under normal operating conditions. Honeywell’s global gas safety support team provides 24/7 technical assistance, with certified engineers available to assist with configuration, detector integration, and safety loop validation—critical issues are addressed within 4 hours.

We offer on-site commissioning services, including detector calibration verification, HART communication setup, and integration with Safety Manager/Experion PKS. Extended warranty options (up to 7 years) include annual preventive maintenance, firmware updates, and priority access to replacement parts. In the event of a fault, Honeywell maintains regional stock of FC-TSGAS-1624 modules, enabling next-day delivery to minimize safety system downtime. All repairs use genuine components, ensuring the module retains its original isolation ratings, accuracy, and safety certifications. This commitment reflects Honeywell’s dedication to industrial safety and customer operational confidence.