Description

Detailed parameter table

| Parameter name | Parameter value |

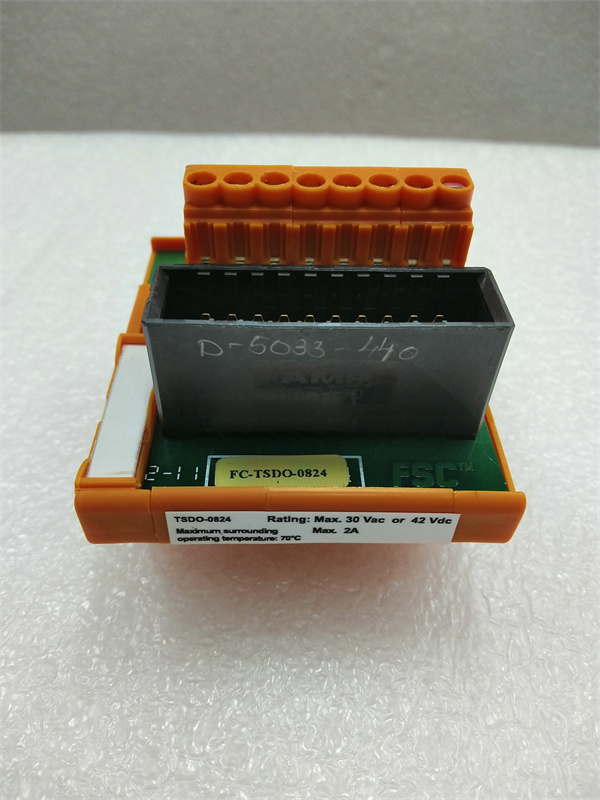

| Product model | FC-TSDO-0824 |

| Manufacturer | Honeywell |

| Product category | Safety digital output module |

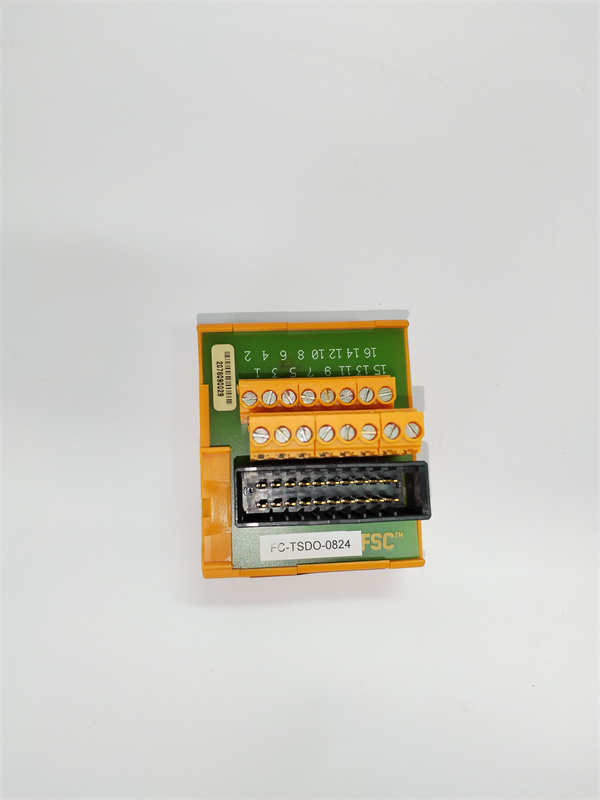

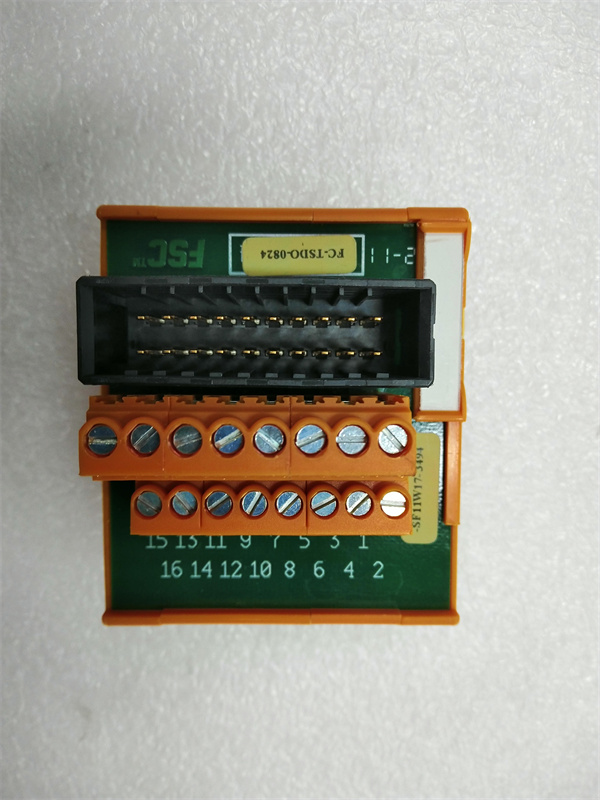

| Number of channels | 8 (isolated) |

| Output type | Relay (changeover), 250 V AC / 30 V DC |

| Maximum switching current | 5 A per channel (resistive load) |

| Safety integrity level | SIL 2 (per IEC 61508) |

| Response time | ≤10 ms |

| Isolation rating | 3 kV AC (channel to channel, channel to backplane) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 12 W |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 130 mm x 100 mm x 75 mm (5.12 in x 3.94 in x 2.95 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Safety Manager, Experion PKS, FC-TSGAS-1624 |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61508, ATEX, IECEx, UL 508 |

Honeywell FC-TSDO-0824

Product introduction

The FC-TSDO-0824 is a high-reliability safety digital output module from Honeywell, engineered to serve as a critical execution layer in industrial safety systems. As a key component of Honeywell’s safety I/O portfolio, this module is designed to translate safety controller commands into physical actions, controlling emergency shutdown devices, alarms, and isolation equipment with precise timing and fault tolerance.

FC-TSDO-0824 features 8 isolated relay outputs, each capable of switching high-power loads while maintaining SIL 2 integrity—making it ideal for safety-critical applications where failure to act could endanger personnel or assets. It integrates seamlessly with Honeywell’s Safety Manager for coordinated emergency shutdown (ESD) sequences and works with Experion PKS for centralized monitoring of output status. Whether deployed in oil refineries, chemical plants, or power generation facilities, FC-TSDO-0824 ensures reliable activation of safety barriers, from shutdown valves to alarm sirens, forming the final link in a robust safety chain.

Core advantages and technical highlights

SIL 2 safety compliance: FC-TSDO-0824 meets the stringent requirements of SIL 2 per IEC 61508, ensuring it can be trusted in safety loops where failure could lead to hazardous events. Its design includes redundant relay drivers, built-in self-diagnostics (with 99% fault coverage), and monitoring of contact wear—detecting faults like welded contacts or open circuits and triggering immediate alerts. This level of reliability is critical in applications such as emergency shutdown systems, where a failed output could prevent a valve from closing during a gas leak.

Isolated channels: Each of the 8 channels features 3 kV AC isolation from other channels and the backplane, eliminating cross-talk and protecting the module from voltage spikes or ground loops. This isolation ensures a fault in one channel (e.g., a short circuit in a shutdown valve) does not affect others, maintaining system integrity in distributed safety loops. For example, in a chemical plant with multiple isolation valves, a fault in one valve’s circuit won’t disable the module’s ability to actuate others.

High-power relay outputs: With 5 A switching capacity per channel, FC-TSDO-0824 can directly control heavy-duty devices like motorized shutdown valves, contactors, and alarm horns without external amplifiers. This simplifies system design and reduces potential failure points, as fewer components are involved in the safety loop. The relays’ changeover contacts (1 normally open + 1 normally closed) also enable status feedback, allowing the module to verify that an output action was executed successfully.

Extreme environment resilience: Built to operate in temperatures ranging from -40°C to +70°C, FC-TSDO-0824 thrives in harsh industrial settings—from arctic pipelines to desert refineries. Its rugged construction resists vibration, humidity, and electromagnetic interference (EMI), ensuring reliable performance in conditions that would degrade standard output modules. This durability minimizes maintenance needs in remote or hard-to-access locations.

Typical application scenarios

In oil and gas production facilities, FC-TSDO-0824 acts as the execution layer for wellhead safety systems. It connects to Safety Manager, receiving commands to actuate emergency shutdown valves (ESVs) when hazardous gas levels (detected by FC-TSGAS-1624) exceed thresholds. The module’s 5 A relays directly control the valve actuators, while normally closed contacts provide feedback to confirm valve closure. Its fast response time (<10 ms) ensures ESVs close within critical time windows, preventing gas leaks from escalating into explosions.

Chemical processing plants utilize FC-TSDO-0824 in batch reactor safety loops. It controls emergency isolation valves, rupture disc actuators, and area alarms, activating them if temperature or pressure sensors detect dangerous conditions. The module’s isolated channels prevent cross-contamination between reactor zones, ensuring a fault in one reactor’s safety system doesn’t affect others. Integration with Experion PKS allows operators to monitor output status, verifying that safety actions were executed as intended.

Wastewater treatment plants deploy FC-TSDO-0824 to manage biogas safety systems. It activates ventilation fans, gas flare igniters, and emergency stop circuits for digester pump

Honeywell FC-TSDO-0824

s when methane levels exceed 50% LEL. The module’s wide temperature range ensures reliable operation in the humid, corrosive environment of digester control rooms, while its SIL 2 certification guarantees it can be trusted to prevent explosive buildup.

Related model recommendations

FC-TSDO-1624: A 16-channel variant of FC-TSDO-0824, ideal for larger safety systems like refinery process units requiring more output points.

FC-QPP-0001: Honeywell’s safety controller that pairs with FC-TSDO-0824 to manage safety logic, extending system capabilities to SIL 3 when used in redundant configurations.

FC-TSGAS-1624: Gas detection interface module that works with FC-TSDO-0824 in gas safety loops, triggering output actions when hazardous levels are detected.

XNX Safety Relay: Supplementary relay module for FC-TSDO-0824 that handles loads exceeding 5 A, such as large motorized valves, while maintaining safety integrity.

FC-PS24-3A: Redundant 24 V DC power supply optimized for FC-TSDO-0824, ensuring uninterrupted operation during power fluctuations.

Safety Manager: Honeywell’s safety instrumented system that coordinates FC-TSDO-0824 with input modules, executing complex ESD sequences based on process hazards.

FC-TSDI-16: Digital input module that complements FC-TSDO-0824, providing feedback on output device status (e.g., valve position) for closed-loop safety control.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-TSDO-0824, ensure the DIN rail is mounted in a dust-free enclosure (explosion-proof if in hazardous areas) with ambient temperature between -40°C and +70°C. Use a torque wrench set to 1.0 Nm to secure the module. Verify the 24 V DC power supply is isolated, fused (2A), and grounded to prevent noise. Use 1.5 mm² shielded cables for output connections, grounding the shield at the module end to minimize EMI. Route power and signal cables separately, and label each channel with the connected device (e.g., “ESV-101”) for easy troubleshooting.

Maintenance suggestions: For FC-TSDO-0824, perform monthly visual inspections to check for loose connections or signs of overheating (discoloration). Test relay operation quarterly by simulating safety commands and verifying contact closure with a multimeter—replace the module if contacts show resistance >100 mΩ. Use Honeywell’s Safety Builder software to run diagnostic scans monthly, checking for relay wear or driver faults. Calibrate response time annually using an oscilloscope to ensure it remains <10 ms. Always replace with Honeywell-certified spares to maintain SIL 2 integrity, and back up configuration settings to a secure device.

Service and guarantee commitment

FC-TSDO-0824 is backed by Honeywell’s 5-year warranty, covering manufacturing defects and ensuring compliance with SIL 2 and hazardous area certifications under normal operating conditions. Honeywell’s global safety support team provides 24/7 technical assistance, with certified engineers available to assist with configuration, loop testing, and safety validation—critical issues are addressed within 4 hours.

We offer on-site commissioning services, including relay contact testing, integration with Safety Manager, and verification of response times. Extended warranty options (up to 7 years) include annual preventive maintenance, firmware updates, and priority access to replacement parts. In the event of a fault, Honeywell maintains regional stock of FC-TSDO-0824 modules, enabling next-day delivery to minimize safety system downtime. All repairs use genuine components, ensuring the module retains its original isolation ratings, switching capacity, and safety certifications. This commitment reflects Honeywell’s dedication to industrial safety and customer operational reliability.