Description

Detailed parameter table

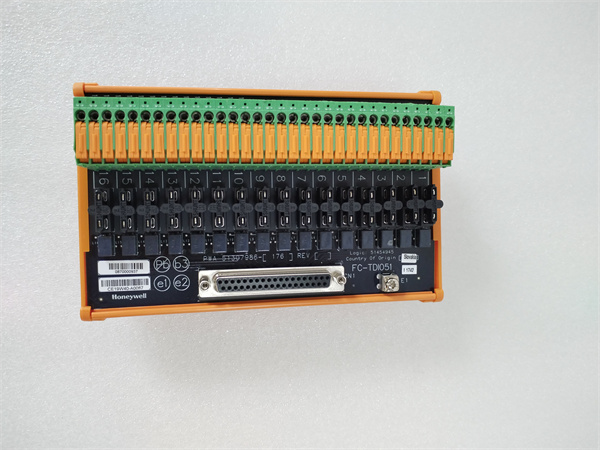

| Parameter name | Parameter value |

| Product model | FC-TDIO51 |

| Manufacturer | Honeywell |

| Product category | Mixed digital I/O module |

| Number of channels | 16 (8 digital inputs, 8 digital outputs) |

| Input type | 24 V DC, PNP/NPN configurable |

| Output type | Relay (changeover), 250 V AC/30 V DC |

| Maximum switching current | 5 A per output channel (resistive load) |

| Safety integrity level | SIL 2 (per IEC 61508) |

| Response time | Input: ≤2 ms; Output: ≤5 ms |

| Isolation rating | 2.5 kV AC (channel to backplane) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | Max 12 W |

| Operating temperature range | -20°C to +60°C (-4°F to +140°F) |

| Dimensions (LxWxH) | 130 mm x 90 mm x 70 mm (5.12 in x 3.54 in x 2.76 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Experion PKS, Safety Manager |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61508, CE, UL, ATEX |

Honeywell FC-TDIO51

Product introduction

The FC-TDIO51 is a versatile mixed digital I/O module from Honeywell, engineered to streamline connectivity in industrial automation and safety systems. As part of Honeywell’s distributed I/O portfolio, this module combines 8 digital inputs and 8 relay outputs in a single compact unit, serving as a critical interface between field devices and control systems.

FC-TDIO51 excels in bridging safety and standard automation functions, with its SIL 2 certification ensuring reliability in safety-critical loops while supporting general-purpose control tasks. Its configurable inputs accommodate both PNP and NPN sensors, while relay outputs handle a range of actuators, from small solenoids to alarm horns. Whether integrated into Honeywell’s Experion PKS or Safety Manager systems, FC-TDIO51 reduces cabinet space requirements, simplifies wiring, and enhances system flexibility—making it a go-to solution for diverse industrial environments, from chemical plants to manufacturing facilities.

Core advantages and technical highlights

Mixed I/O efficiency: By integrating 8 inputs and 8 outputs in one module, FC-TDIO51 eliminates the need for separate input and output units, reducing hardware costs and saving up to 40% of cabinet space compared to discrete modules. This compact design is particularly valuable in crowded control panels, such as those in retrofitted production lines where space is limited. The balanced channel count also simplifies system design for applications requiring symmetric I/O, like machine control stations with equal numbers of sensors and actuators.

Dual-purpose functionality: FC-TDIO51’s SIL 2 certification allows it to operate in both safety and standard control loops, eliminating the need for separate safety-rated and general-purpose modules. For example, in a packaging line, it can monitor emergency stops (safety input) and control conveyor motors (standard output) simultaneously. This dual role reduces inventory complexity and simplifies integration, as engineers work with a single module type across multiple system layers.

Flexible sensor compatibility: The module’s digital inputs are configurable for PNP or NPN signals via software, supporting seamless integration with third-party sensors—from proximity switches to emergency stop buttons. This eliminates the need for signal converters, reducing potential failure points and cutting installation time. Inputs also feature built-in surge protection (2 kV) to withstand electrical noise, ensuring stable operation near motors or welding equipment.

Robust output performance: FC-TDIO51’s relay outputs deliver 5 A switching capacity, handling higher loads than many competing mixed modules. This allows direct control of devices like small motors or heating elements without external contactors, simplifying wiring and improving response times. Relay contacts are rated for 100,000 electrical operations, ensuring long service life in high-cycle applications such as automated assembly machines.

Typical application scenarios

In chemical processing plants, FC-TDIO51 monitors and controls batch reactor systems. Its inputs connect to level switches and pressure sensors (PNP type) to track process conditions, while outputs activate isolation valves and agitator motors. The module’s SIL 2 rating ensures safe shutdowns if pressure exceeds thresholds, while its mixed design reduces the number of modules needed in the reactor’s control cabinet. Integration with Experion PKS allows operators to monitor both input status and output actions via a single HMI screen.

Automotive body shops utilize FC-TDIO51 to manage robotic welding cells. Inputs detect door interlock switches (NPN) and light curtain breaks, while outputs control weld gun actuation and cell access lights. The module’s fast input response time (≤2 ms) ensures immediate detection of safety breaches, triggering output relays to stop welding operations within 5 ms—critical for protecting workers from hazardous motion. Its rugged design withstands the electromagnetic interference common in welding environments.

Food and beverage facilities deploy FC-TDIO51 in filling line control. Inputs monitor bottle presence sensors and cap verification switches, while outputs control filling valves and reject mechanisms. The relay outputs’ 250 V AC rating allows direct connection to line contactors, simplifying the control chain. Its wide operating temperature range (-20°C to +60°C) ensures reliability in cold storage areas and near steam-heated cleaning stations, maintaining consistent performance in harsh food processing environments.

Honeywell FC-TDIO51

Related model recommendations

FC-TDIO52: A high-density variant of FC-TDIO51 with 16 inputs and 16 outputs, ideal for larger systems like warehouse automation where more I/O points are needed.

FC-QPP-0001: Honeywell’s safety controller that pairs with FC-TDIO51 to manage complex safety logic, extending system capabilities to SIL 3 in high-risk applications.

FS-SDI-16: 16-channel safety digital input module that complements FC-TDIO51 in systems requiring additional safety inputs beyond its 8-channel capacity.

FC-PS24-2A: 24 V DC power supply optimized for FC-TDIO51, providing stable voltage with overload protection to support the module’s 12 W power consumption.

XP101: Explosion-proof enclosure for FC-TDIO51, certified for ATEX Zone 2 areas, enabling safe operation in facilities with flammable vapors.

Experion PKS SCADA: Honeywell’s distributed control system that integrates with FC-TDIO51 for centralized monitoring and control of industrial processes.

FC-TAO8: Analog output module that works with FC-TDIO51 to add 4-20 mA control capabilities, suitable for applications requiring variable speed drives or proportional valves.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-TDIO51, ensure the DIN rail is securely mounted in a dust-free enclosure with ambient temperature between -20°C and +60°C. Use a torque wrench set to 0.8 Nm to fasten the module, ensuring a stable fit. Verify the 24 V DC power supply is regulated, grounded, and protected by a 1A fuse. Use shielded twisted-pair cables (0.5 mm² minimum) for input connections, routing them separately from power cables to minimize EMI. For outputs, use 1.5 mm² cables to handle the 5 A current, and label all channels clearly to simplify troubleshooting.

Maintenance suggestions: For FC-TDIO51, perform monthly visual inspections to check for loose terminals or signs of overheating (discoloration). Test input channels quarterly using a signal generator to verify response times (<2 ms) and ensure PNP/NPN configuration matches connected sensors. Annually, check relay outputs with a multimeter to detect contact wear—replace the module if continuity resistance exceeds 100 mΩ. Back up configuration settings to a secure device via Honeywell’s configuration software, and avoid hot-swapping during operation to prevent system disruptions. Use only Honeywell-certified spares to maintain SIL 2 integrity.

Service and guarantee commitment

FC-TDIO51 is backed by Honeywell’s 3-year warranty, covering manufacturing defects and ensuring compliance with SIL 2 specifications under normal operating conditions. Honeywell’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and integration, with critical issues addressed within 8 hours.

We offer on-site commissioning services, including channel testing, safety loop validation, and software integration with Experion PKS. Extended warranty options (up to 5 years) include annual preventive maintenance checks to verify isolation ratings and relay performance. In the event of a fault, Honeywell maintains regional stock of FC-TDIO51 modules, enabling next-day delivery to minimize downtime. All repairs use genuine components, ensuring the module retains its original safety certifications and operational reliability. This commitment reflects Honeywell’s dedication to industrial efficiency and customer peace of mind.