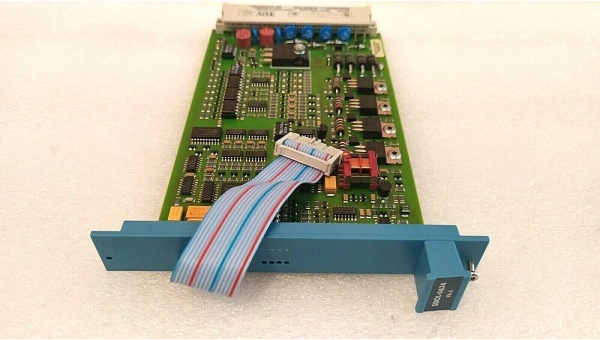

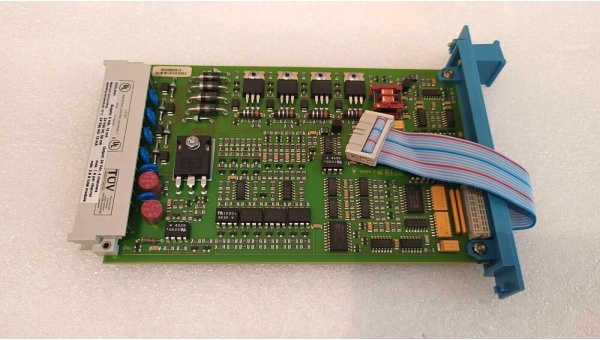

Description

Key Technical Specifications

- Model Number: FC-SDOL-0424

- Manufacturer: Honeywell Process Solutions

- Output Channels: 4 independent 24VDC safe digital outputs (fail-safe, normally de-energized)

- Output Voltage Range: 18–32VDC (operational)

- Output Current: 2A per channel (continuous); 5A per channel (peak, 1s max)

- Power Supply: Dual redundant 24VDC inputs, 1.0A max total current draw

- Safety Rating: SIL 3 capable when used in FSC SIS architectures (per IEC 61508)

- Isolation Rating: 2500V AC (field-to-logic; 1-minute dielectric test); 500V AC (channel-to-channel)

- Fail-Safe State: De-energized (valves default to safe position on power loss or module fault)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Enclosure Rating: IP20 (rack-mounted for control cabinet installation)

- Certifications: TÜV, UL 508S, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

- Diagnostic Capabilities: Per-channel short-circuit detection, open-load detection, power supply fault monitoring, module health status reporting

Honeywell FC-SDOL-0424

Field Application & Problem Solved

In refineries, chemical plants, and LNG terminals, the single biggest risk to process safety is a digital output module that fails to trigger an emergency shutdown (ESD) when a hazard is detected. Legacy non-safety DO modules often lack fail-safe logic—they can get stuck in the “energized” state during a fault, leaving solenoid valves open and processes exposed to catastrophic risks like overpressure or fire. The FC-SDOL-0424 solves this with a normally de-energized fail-safe design: if power is lost, the module faults, or the FSC controller triggers a shutdown, all channels de-energize instantly, forcing final elements (like ESD valves) into their pre-defined safe positions.

You’ll find this module in every FSC SIS installation: controlling emergency shutdown valves on crude distillation units, activating fire suppression system solenoids, and tripping motor shutdown relays on pump skids. Its core value is safety compliance— it’s SIL 3 capable, which means it meets the highest global standards for safety instrumented systems. Unlike standard DO modules, it provides diagnostic feedback for each channel, so you can detect a failed solenoid valve or broken wire before a hazard occurs. This predictive visibility cuts unplanned downtime by letting you replace faulty components during scheduled turnarounds instead of emergency shutdowns.

Another critical problem it addresses is channel isolation. In high-EMI environments like turbine halls or VFD rooms, cross-channel interference can cause false valve actuation. The FC-SDOL-0424’s 500V channel-to-channel isolation prevents this, ensuring a fault in one ESD loop never impacts another. I’ve seen this module prevent a false shutdown of a gasoline blending unit— a nearby VFD fried a non-isolated module, but the FC-SDOL-0424 kept running without a glitch.

Installation & Maintenance Pitfalls (Expert Tips)

Fail-Safe Wiring Must Match Valve Safe Position

Rookies often wire solenoid valves to the FC-SDOL-0424 without verifying the valve’s fail-safe position. For example, a valve that fails closed (FC) requires the module to energize to open it—if you wire it backwards, a module fault will open the valve instead of closing it, creating a hazard. Always cross-reference the valve’s datasheet with the module’s wiring diagram: normally de-energized = valve in safe position; energized = valve in operating position. Test the fail-safe logic during commissioning by cutting power to the module— confirm all valves move to their safe positions immediately. This 10-minute test can prevent a disaster.

Don’t Skip Load Matching for Solenoid Valves

The module’s 2A continuous current rating is non-negotiable. Oversizing the load (e.g., connecting a 3A solenoid) will cause the channel to overheat and trip, leading to unplanned shutdowns. Undersizing the load (e.g., a 0.5A solenoid with no dummy load) can cause unstable switching and false diagnostics. Calculate the total load current (including cable resistance) for each channel— if it’s below 0.5A, add a 1.5kΩ dummy load to stabilize the circuit. I’ve fixed a failed fire suppression system where a tech connected a 2.5A solenoid to the module; swapping it for a 2A-rated solenoid solved the issue.

Redundant Power Inputs Need Separate Safety-Class Supplies

A common mistake is connecting both redundant power inputs to the same 24VDC supply— this defeats the purpose of redundancy in a safety system. If the supply fails, the module de-energizes all channels, which is correct for safety, but it should only happen if the SIS triggers it, not a single power glitch. Connect each input to a separate safety-class 24VDC supply (e.g., one from the FSC rack, one from a standalone safety power unit). During commissioning, test power failover by unplugging one supply— the module should continue operating without channel faults or diagnostic alerts.

Diagnostic Alerts Are Not “Nuisance” — Investigate Them Immediately

Techs often ignore open-load or short-circuit alerts from the FC-SDOL-0424, thinking they’re caused by temporary wiring issues. An open-load alert on an ESD valve channel means the solenoid wire is broken— if a hazard occurs, the valve won’t actuate. A short-circuit alert means the wire is grounded— this can cause the module to overheat and fail. Set up HMI alarms that require a maintenance work order to be created for every diagnostic fault. I’ve seen a plant avoid a tank overpressure incident by fixing an open-load alert on an ESD valve channel— the wire was corroded and would have failed during the next pressure spike.

Honeywell FC-SDOL-0424

Technical Deep Dive & Overview

The Honeywell FC-SDOL-0424 is a purpose-built safe digital output module for the FSC fail-safe control system, designed from the ground up for safety-critical applications. At its core, each of the 4 channels uses a dedicated fail-safe relay and optocoupler to ensure the normally de-energized state is maintained unless the FSC controller explicitly commands it to energize. The 2500V field-to-logic isolation protects the FSC controller from high-voltage transients in the field, while the 500V channel-to-channel isolation prevents cross-talk in high-EMI environments.

The module’s dual redundant power inputs feed into a built-in power management circuit that prioritizes the primary supply but switches to the secondary in less than 1ms if the primary fails. This ensures uninterrupted operation during power glitches, while still maintaining fail-safe logic if both supplies are lost. The diagnostic engine continuously monitors each channel for open loads, short circuits, and overcurrent conditions, sending real-time data to the FSC controller via the backplane bus.

Unlike standard DO modules, the FC-SDOL-0424 does not have a “force” function— you cannot override the fail-safe state from the HMI. This is a deliberate design choice to prevent unauthorized tampering with safety loops. Its IP20 rating means it’s meant for indoor control cabinet installation; if you need to mount it in a hazardous area, pair it with a NEMA 4X enclosure rated for Zone 2.

In the field, this module’s strength is its uncompromising focus on safety. It has no user-programmable logic to misconfigure, no moving parts to wear out, and a fail-safe design that errs on the side of process protection. With proper installation (correct valve wiring, load matching, redundant power) and proactive maintenance (acting on diagnostic alerts), it will run for 10+ years without unplanned failures, making it the backbone of reliable FSC SIS installations.