Description

Key Technical & Application Characteristics

- Bus Compatibility & Signal Transmission: As an I/O bus-oriented module, FC-IOBUS-CPIO2 is highly compatible with Honeywell’s FC series bus protocols. It is mainly used for the transmission of digital switching signals, and can stably connect with the DCS main controller through the industrial bus. It supports multi-point signal parallel transmission, which can meet the signal interaction needs of multiple on-site digital devices at the same time. Its internal circuit adopts anti-interference design, which can resist electromagnetic interference in industrial sites and reduce signal loss or error during transmission.

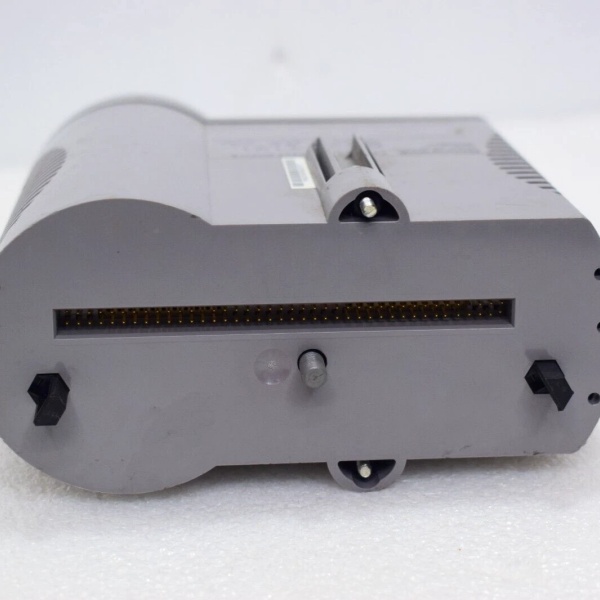

- Physical & Installation Traits: Following the consistent modular design of Honeywell FC series modules, the product has a compact structure and is suitable for installation in standard industrial control cabinets. It adopts a rail or card-type installation method that is common in industrial control, which is convenient for engineers to assemble and disassemble during system debugging and maintenance. The wiring interface adopts standard industrial terminals, which is compatible with common industrial cables and reduces wiring difficulty.

- Field Application Scenarios: It is widely used in process industries with high requirements for control stability, such as petroleum refining, chemical production, and thermal power generation. In chemical production workshops, it can connect digital limit switches, solenoid valves and other equipment on the reaction kettle, transmit the on-off state of the equipment to the central DCS, and at the same time receive control signals from the controller to control the start and stop of the on-site equipment. In thermal power plants, it is used in the auxiliary control system of boilers to realize the signal transmission between the ash removal equipment, feeding equipment and the central control system, ensuring the continuous and stable operation of the production line.

Honeywell CC-PFB801

Installation & Maintenance Notes

- Confirm Bus Protocol Matching: When integrating with the DCS system, it is necessary to confirm that the bus protocol of the controller is consistent with the module. Although the module has good compatibility, mismatched protocol versions will lead to communication failure. It is recommended to check the system configuration manual in advance and complete the protocol matching setting before power-on.

- Ensure Firm Wiring Connection: The module relies on stable wiring to realize signal transmission. When connecting the terminal, use professional tools to fasten the cable to avoid poor contact caused by loose wiring, which may lead to signal fluctuation or interruption. After wiring, use a multimeter to test the continuity of the line to eliminate hidden dangers of wiring.

- Avoid Adjacent Installation with High-power Equipment: High-power equipment such as industrial frequency converters will generate strong electromagnetic radiation during operation. Installing FC-IOBUS-CPIO2 close to such equipment will interfere with its signal transmission. It is recommended to keep a safe distance of more than 30cm during installation, or use a metal partition to isolate it if the installation space is limited.

- Regularly Conduct Communication Detection: During daily maintenance, use industrial bus diagnostic tools to check the module’s signal transmission rate and error rate. If abnormal phenomena such as delayed signal response are found, timely check whether the module’s interface is corroded and whether the bus line is aging, and clean or replace the parts in time to ensure the stable operation of the industrial control system.

Honeywell CC-PFB801