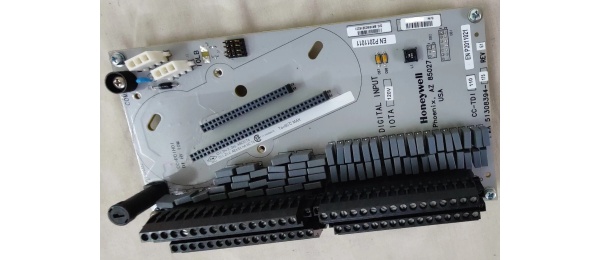

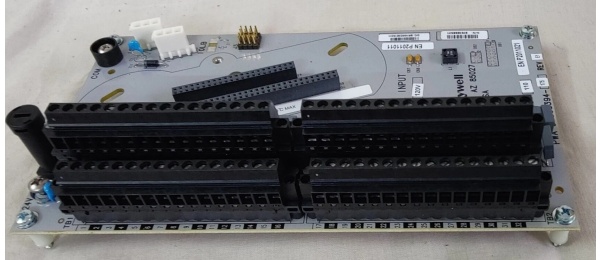

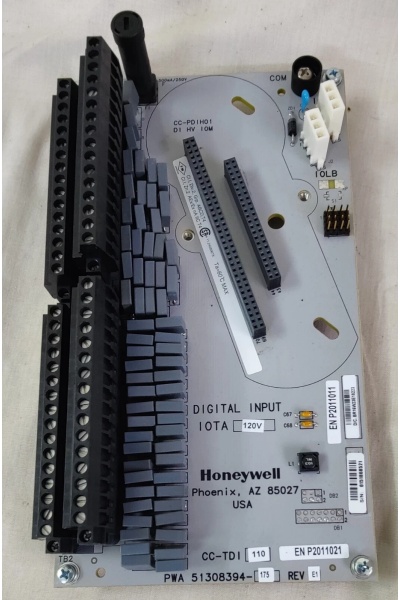

Description

Key Technical Specifications

- Model Number: CC-TDI220

- Manufacturer: Honeywell Process Solutions

- Input Channels: 24 independent 24VDC digital inputs (sink/source configurable)

- Input Voltage Range: 18–32VDC (operational); High = >15VDC, Low = <9VDC

- Input Current: 3mA @ 24VDC (nominal)

- Power Supply: Dual redundant 24VDC inputs, 0.8A max total current draw

- Isolation Rating: 500V AC (channel-to-channel; 1-minute dielectric test); 1500V AC (field-to-backplane)

- Hot-Swap Capability: Yes (supports module replacement without controller shutdown)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Enclosure Rating: IP20 (rack-mounted for control cabinet installation)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

- Diagnostic Capabilities: Open-circuit, short-circuit, and overvoltage detection per channel

Honeywell CC-TDI220

Field Application & Problem Solved

In refineries, chemical plants, and power generation facilities running Experion PKS, the biggest headache with digital input modules is channel cross-talk and undetected wiring faults—both of which lead to false process alarms or missed critical signals (e.g., a failed ESD valve position switch). Legacy non-isolated DI modules let faults in one channel take down an entire bank of inputs, forcing costly process shutdowns to troubleshoot. The CC-TDI220 solves this with 500V channel-to-channel isolation, so a shorted or grounded channel never impacts neighboring inputs.

You’ll find this module in every critical Experion PKS I/O rack: monitoring limit switch positions on crude oil pipeline valves, tracking proximity sensor status on conveyor belts in pulp mills, and verifying pressure switch trips on boiler feedwater systems. Its core value is diagnostic transparency—every channel reports open-circuit, short-circuit, and overvoltage faults directly to the Experion PKS HMI, eliminating the need for manual multimeter checks in the field. Unlike basic DI modules, it doesn’t just tell you a channel is “on” or “off”—it tells you why it’s faulted, cutting troubleshooting time from hours to minutes.

Another critical problem it addresses is hot-swap capability. During planned turnarounds or unplanned module failures, you can replace the CC-TDI220 without shutting down the Experion PKS controller—this is a game-changer for continuous processes like ethylene production, where even a 10-minute shutdown costs six-figure losses. Its dual redundant power inputs also mean you can hook it up to two separate 24VDC supplies, eliminating power as a single point of failure in safety-critical loops.

Installation & Maintenance Pitfalls (Expert Tips)

Sink/Source Configuration Is Non-Negotiable

The CC-TDI220 is configurable for sink or source input mode, but rookies often skip this step and wire the module to match the wrong mode. For sink mode, the field device supplies the 24VDC; for source mode, the module supplies the 24VDC to the field device. Wiring a source-mode sensor to a sink-configured channel will result in a permanent “low” signal; wiring a sink-mode switch to a source-configured channel will short the module’s 24VDC supply. Always confirm the field device’s input type before configuring the module via Experion PKS Configuration Studio—save the configuration to the controller’s memory to avoid rework during replacement.

Don’t Ignore Shield Grounding for Long Cable Runs

For field cables longer than 100 meters, ungrounded shields will pick up EMI from nearby VFDs or high-voltage motors, causing intermittent “flickering” input states. Run the cable shield to a single point ground at the module end—never ground both ends (this creates a ground loop). Use a dedicated ground bus bar for the CC-TDI220, separate from motor or VFD grounds. I’ve fixed a boiler control loop that was tripping false alarms— the issue was a 200-meter ungrounded cable picking up noise from a nearby VFD. A $5 grounding clamp solved the problem instantly.

Redundant Power Inputs Need Separate Power Supplies

A common mistake is daisy-chaining both redundant power inputs to the same 24VDC supply—this defeats the purpose of redundancy. If the supply fails, the module goes offline, taking all 24 channels with it. Connect each power input to a separate, independently fused 24VDC supply (e.g., one from the controller rack, one from a standalone power unit). During commissioning, test power failover by unplugging one supply— the module should keep running without any channel faults or communication drops.

Diagnostic Alerts Are Not “Noise”—Investigate Them

Techs often dismiss the CC-TDI220’s diagnostic alerts as “false positives,” but these alerts almost always indicate a real field issue (e.g., a frayed cable, a failing switch). An open-circuit alert on a valve position switch, for example, could mean the switch’s wiring is damaged—ignoring it could lead to a valve failing to open during a process upset. Set up HMI alarms for all diagnostic faults and require maintenance to investigate every alert within 24 hours. I’ve seen a plant avoid a major pipeline rupture by fixing a frayed cable that triggered an open-circuit alert on the CC-TDI220.

Honeywell CC-TDI220

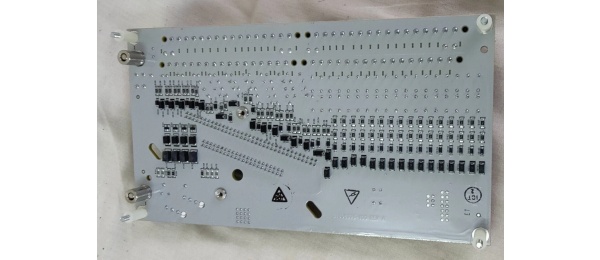

Technical Deep Dive & Overview

The Honeywell CC-TDI220 is an intelligent, isolated digital input module designed for the Experion PKS C-Series I/O rack, with a focus on fault tolerance and diagnostic visibility. At its core, each of the 24 channels uses a dedicated optocoupler to provide 500V channel-to-channel isolation—this means a short circuit in one field device won’t damage the module or disrupt other channels. The module’s sink/source configuration is handled via firmware, with no physical DIP switches to misconfigure, and the configuration is stored in non-volatile memory so it survives power cycles.

The dual redundant power inputs feed into a built-in power management circuit that automatically switches to the secondary supply if the primary fails—switchover time is less than 1ms, so there’s no disruption to channel data or communication with the Experion PKS controller. The module communicates with the controller via the C-Series backplane bus, with a 50ms update rate that ensures real-time signal transmission for critical safety loops.

Its diagnostic engine is a standout feature: it continuously monitors each channel for open circuits, short circuits, and overvoltage conditions. When a fault is detected, it sends a detailed diagnostic code to the controller, which is displayed on the HMI with a clear description of the issue (e.g., “Channel 12: Open Circuit”). Unlike basic DI modules, it doesn’t require external diagnostic tools—all troubleshooting can be done from the control room.

In the field, the CC-TDI220’s strength is its reliability—with proper installation, it runs for 7–10 years without unplanned failures. Its hot-swap capability and redundant power inputs make it ideal for safety-critical applications, and its diagnostic transparency eliminates the guesswork from field troubleshooting. For Experion PKS users, it’s the go-to digital input module for any application where uptime and fault visibility are non-negotiable.